Multi-cleaning type food processing technology for food processing

A food processing, multiple technology, applied in multiple cleaning food processing technology of food processing, multiple cleaning food processing technology field, can solve the problems of water and impurity separation, cleaning quality discount, impurity cannot be processed, etc., to achieve good cleaning, The effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

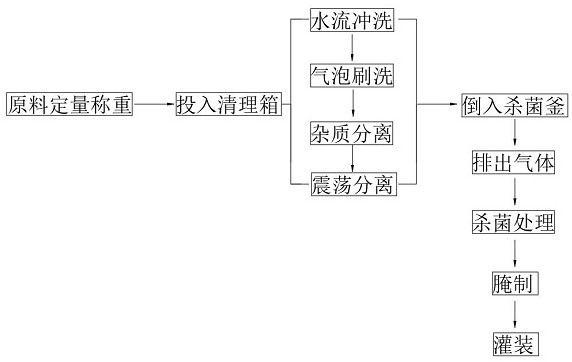

[0033] See Figure 1 , a multi-cleansing food processing process for food processing, characterized by: comprising the following steps,

[0034] S1, weigh raw materials: the raw materials are placed on the weighing machine to weigh, take 80 kg of raw materials, and then pour the raw materials into the cleaning box 1, waiting for the cleaning box 1 to clean up the impurities on the raw materials;

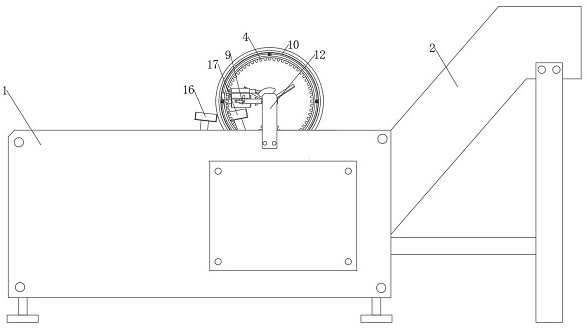

[0035] S2, brush cleaning: through the track in the treatment box 1 to drive the flow of raw materials, the use of water flow in the treatment box 1 reciprocating impact raw materials to remove impurities, and then the use of the brush brush in the treatment box 1 brush to wash raw materials, and finally through the tracks in the treatment box 1 to drive the raw materials out of the inside of the treatment box 1;

[0036] S3, impurity separation: through the treatment box 1 on the filter plate 10 and the water surface in the treatment box 1 contact, and then the floating impurities on the...

Embodiment 2

[0046] The present embodiment is an improvement made on the basis of Example 1, according to Figure 1-6 As shown, the rotating rod 44 is also installed with a adjustment device 3, the rotating rod 44 is used to drive the adjustment device 3 to resist the force block 91, wherein one of the support frames 12 is fixedly installed with a weld sleeve 7, the adjustment device 3 comprises sliding the shaft sleeve 34 connected to the rotary rod 44, the bushing 34 is mounted with a sector plate 32, the fan plate 32 is used to resist the force block 91, the bushing 34 is also provided with a slip sleeve 31, the slip sleeve 31 is connected to the weld sleeve 7 through the second spring 36, Slip sleeve 31 supports the sealing barrel 97 through the support rod 37, the rotary rod 44 is also installed with a squeeze bar 13, the sealing barrel 97 is also installed with a resistance block 15, the extrusion bar 13 is used to resist the resistance block 15.

[0047] In the present embodiment:

[004...

Embodiment 3

[0051] The present embodiment is an improvement made on the basis of Example 1, according to Figure 1-7 As shown, the push rod 94 is also installed with a piston disc 96, the sealing barrel 97 is also installed with a blowing part 6, the blowing component 6 includes a trachea 62 connected to the sealing barrel 97, the sealing barrel 97 is also installed with a gas box 61, the sealing barrel 97 and the gas storage box 61 are connected by the trachea 62, the piston disc 96 is used to squeeze the air inside the sealing barrel 97 to the inside of the trachea 62, the trachea 62 is used to deliver air to the inside of the gas box 61, the blowing plate 14 is also provided with a pore for spraying air 18, The air hole 18 is used to spray air onto the filter plate 10 for desorization, the hitting plate 14 is also installed with a conveyor pipe 65, the conveyor pipe 65 extends to the interior of the gas box 61.

[0052] In the present embodiment:

[0053] Spray gas to remove impurities: accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com