Industrial sulfuric acid solid-liquid separation system

A solid-liquid separation, industrial sulfuric acid technology, applied in separation methods, filtration separation, sulfur compounds and other directions, can solve problems such as water waste, achieve the effect of preventing clogging and improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

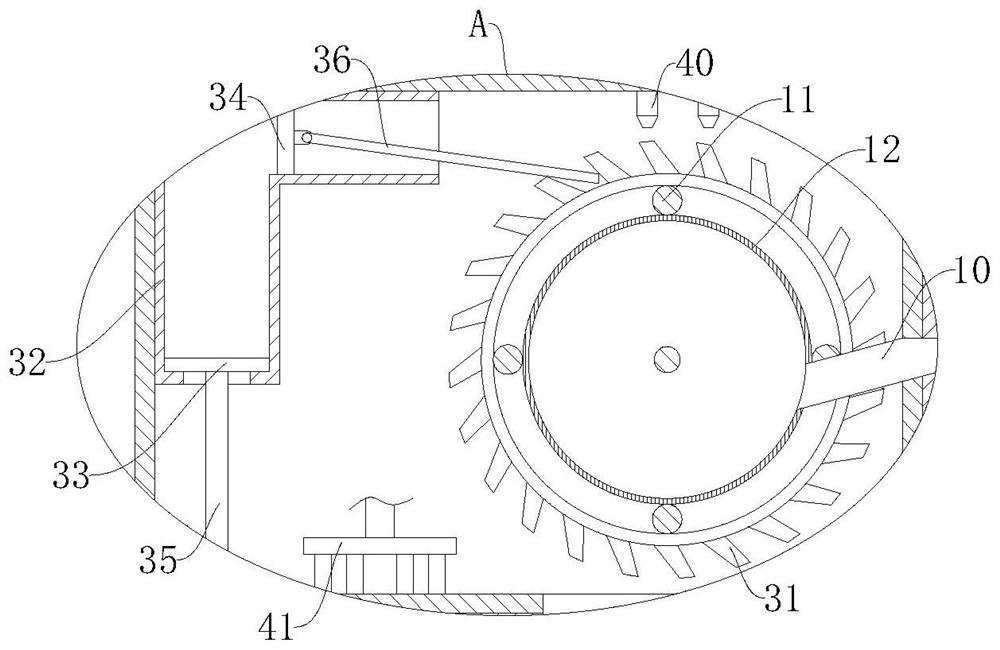

[0050] As an embodiment of the present invention, refer to Figure 4 , the first drive mechanism includes a mounting bracket 23 that is fixedly installed in the funnel 20 horizontally. A reciprocating screw rod 26 is vertically fixedly installed on the top of the reciprocating screw rod 26, a slider 27 is threadedly installed on the reciprocating screw rod 26, and two top rods 28 that cooperate with the second filter plate 21 are vertically fixed and installed on the top wall of the slider 27. A second installation rod 46 is fixed horizontally on the inner wall of the funnel 20 , and a telescopic rod 47 whose output end is fixedly connected to the side wall of the slider 27 is vertically fixed and installed on the second installation rod 46 .

[0051] In the initial state, under the action of gravity, the bottom wall of the second filter plate 21 is in contact with the top of the reciprocating screw rod 26. During the working process, the liquid passing through the first filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com