Composite hydraulic oil cylinder of large-tonnage powder hydraulic forming machine

A technology of hydraulic cylinders and forming machines, which is applied in the direction of material forming presses, stamping machines, presses, etc., and can solve the problems of increased use costs and limited use places

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

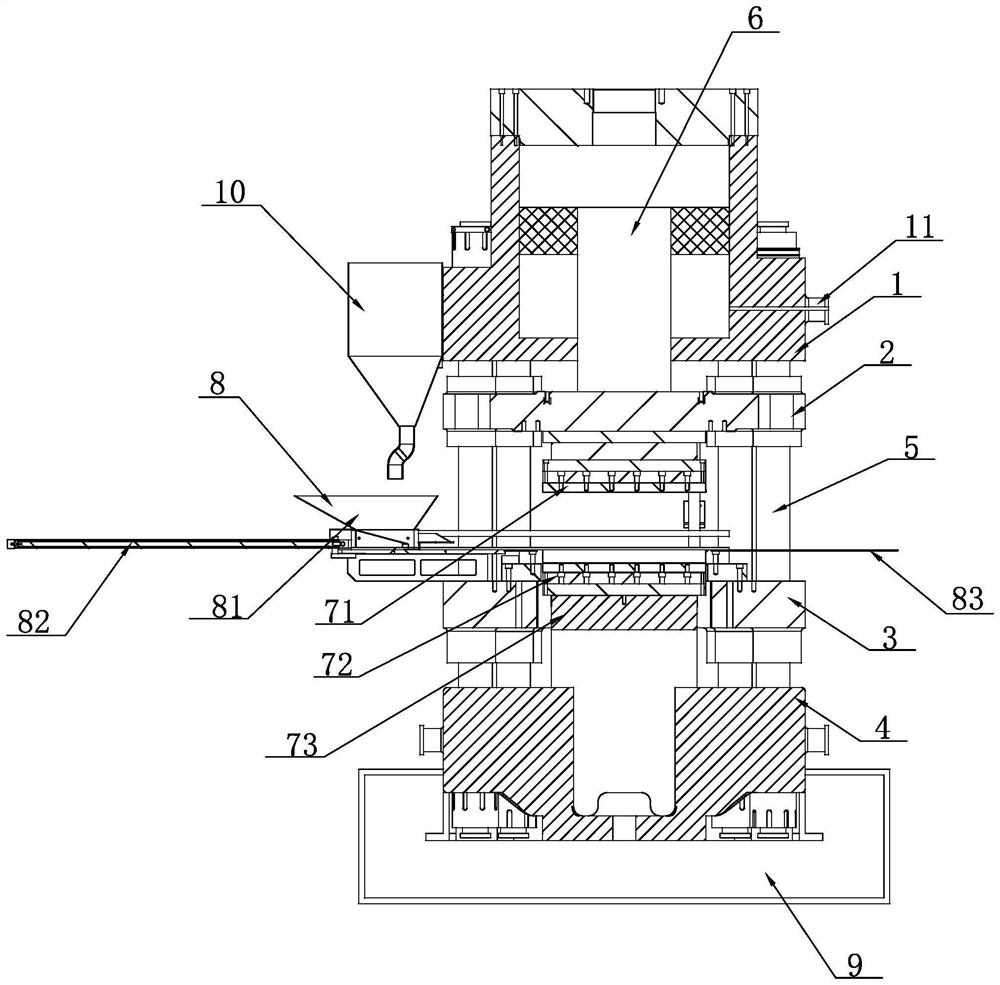

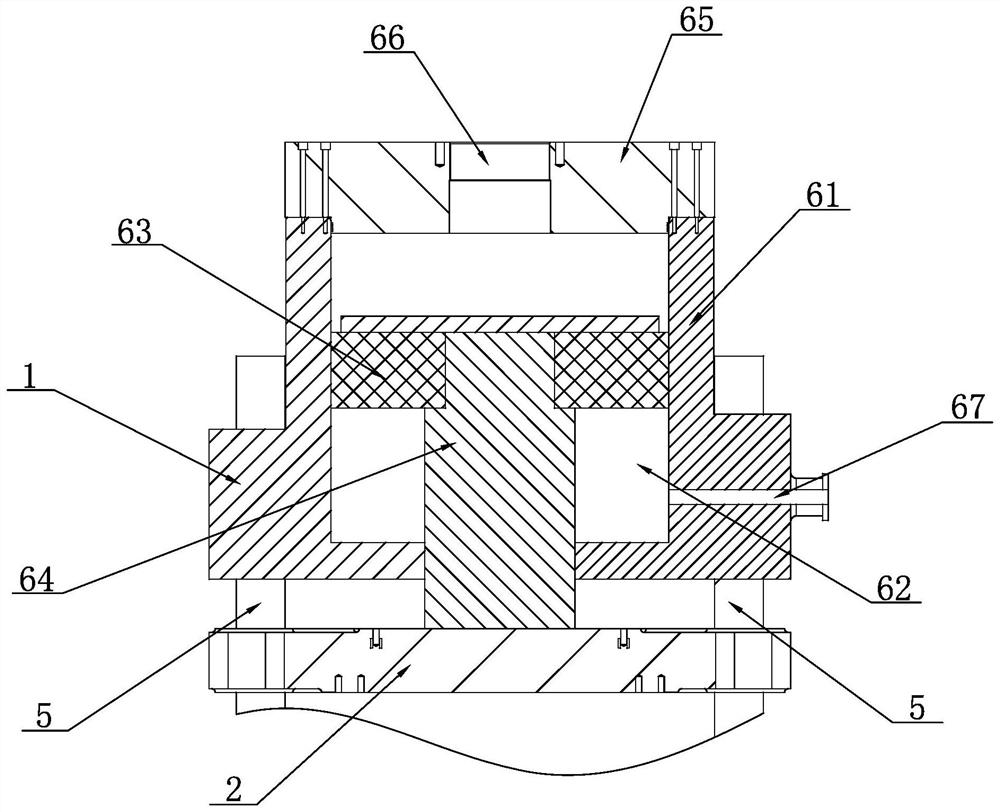

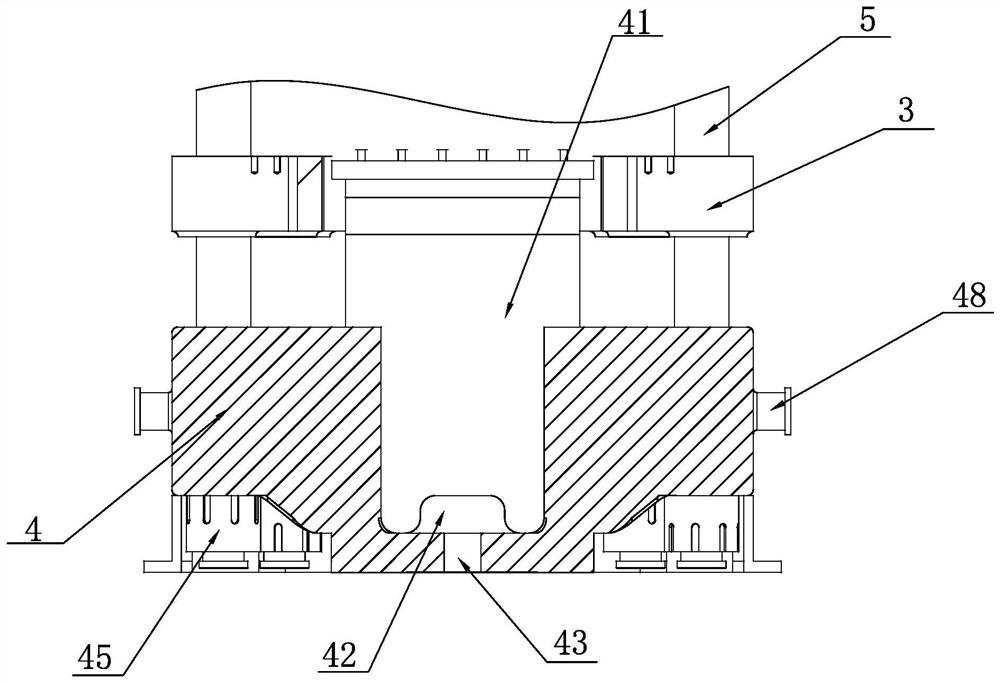

[0027] A composite hydraulic cylinder of a large-tonnage powder hydraulic molding machine, such as Figure 1-7 As shown, it includes an upper fixed plate 1, an upper moving plate 2, a lower moving plate 3, a base 4, eight columns 5, a main pressure cylinder 6, a composite molding die, a feeder 8, an oil storage tank 9 and a powder material tank 10, The eight uprights 5 are divided into four groups and are respectively arranged between the upper fixed plate 1 and the base 4, the two ends of all the uprights 5 are respectively fixed on the upper fixed plate 1 and the base 4, and the upper moving plate 2 and the lower moving plate 3 are respectively sleeved on the upper fixed plate 1 and the base 4. On the eight uprights 5, the upper moving plate 2 and the lower moving plate 3 can slide up and down along the eight uprights 5. The upper fixed plate 1 doubles as the master cylinder 61 of the main hydraulic cylinder 6, and is located in the center of the upper fixed plate 1. The pos...

Embodiment 2

[0030] Embodiment 2: Different from Embodiment 1, in order to further reduce the number of parts, the master cylinder piston 63 and the master cylinder piston rod 64 are an integrated structure; in order to further reduce the self-weight of the equipment, the master cylinder piston rod 64 and The center of the master cylinder piston 63 is provided with a weight reduction cavity 46; in order to further reduce the height of the whole machine and reduce the oil leakage path, the master cylinder block 61 and the cylinder cover plate 65 are integrated.

[0031] In order to facilitate the processing and installation of the upper fixing plate 1 , the upper lifting lugs 11 are symmetrically arranged at equal height positions on the side of the upper fixing plate 1 , and the upper moving oil holes 67 are arranged along the axis of the upper lifting lugs 11 .

[0032]This structure reduces the height of the 6,000-ton powder iso-density press molding machine to 6.43 meters, and the equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com