Essential oil highly inward emulsion and preparation method thereof

A highly introverted, essential oil technology, applied in the directions of essential oils/spices, preservation of fatty substances by additives, and fat generation, can solve problems such as application limitations and toxicity, and achieve high biocompatibility, low cost, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

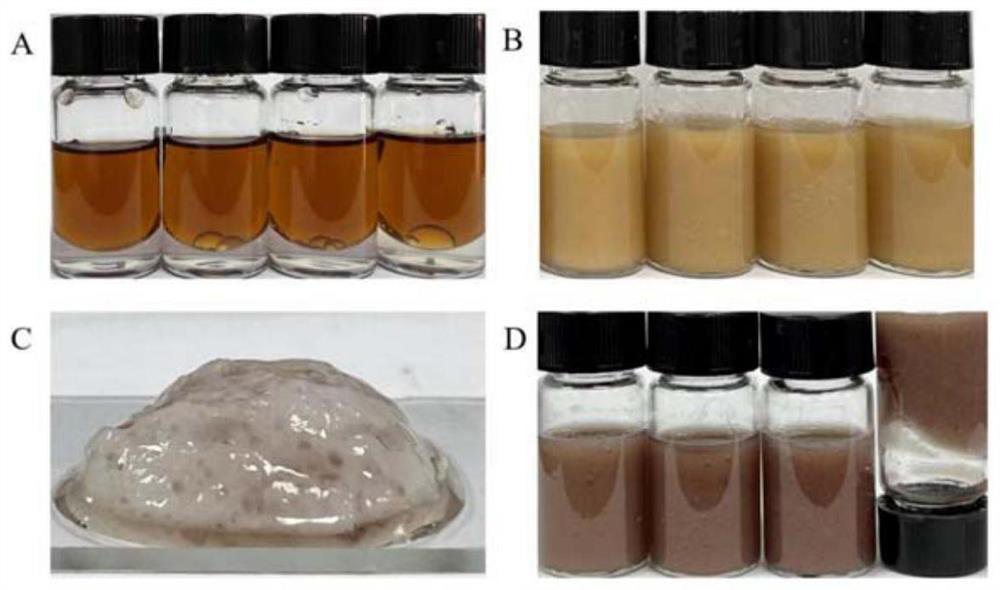

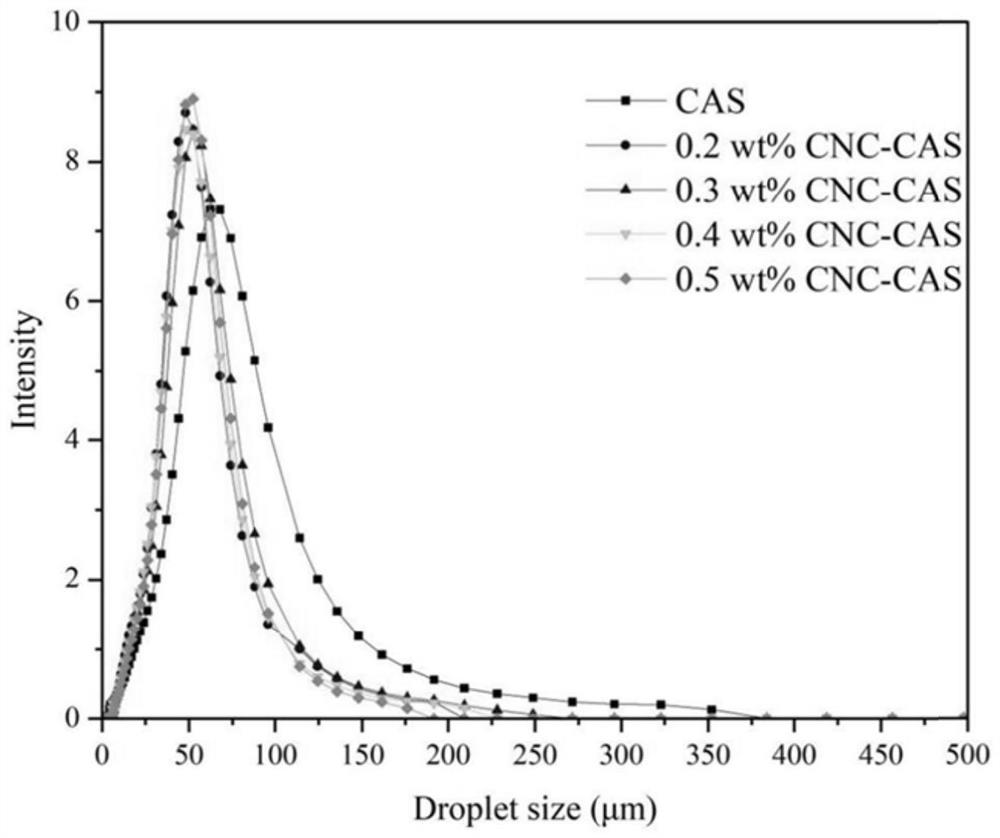

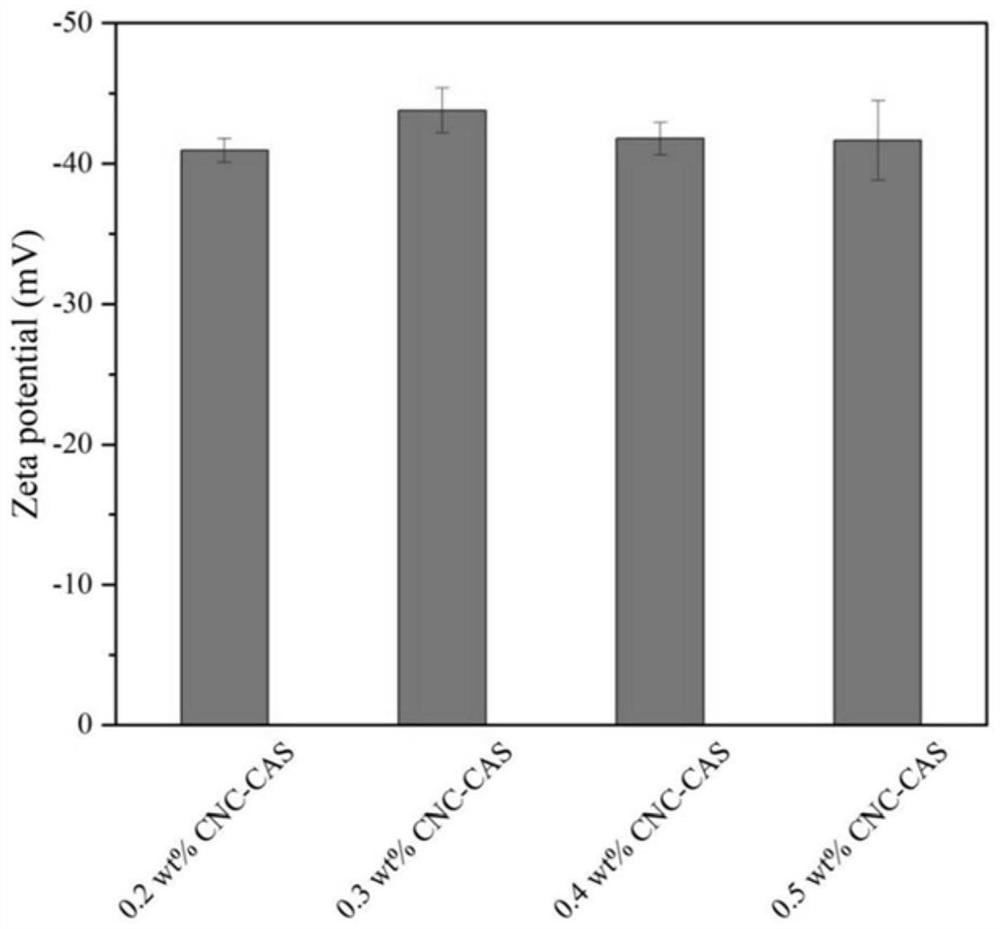

Examples

Embodiment 1

[0063] The preparation method of the high introversion emulsion of essential oil comprises the following steps:

[0064] (1) Preparation of nanocrystalline cellulose

[0065] Disperse 8 g of MCC in 50 mL of sulfuric acid with a mass fraction of 70%, stir vigorously at 50° C. for 10 h, and dilute the reaction mixture with 8 times of water to quench the hydrolysis reaction. Then 8 mL of 30 wt% H was added 2 O 2 solution, a suspension of oxidized nanocrystalline cellulose. After 30 min of reaction, the crystals were separated by centrifugation at 8000 rpm for 10 min, washed with ultrasonic waves, and centrifuged several times to remove excess acid. Finally, dialysis and freeze-drying were carried out to prepare nanocrystalline cellulose.

[0066] (2) Preparation of gelatinized soluble starch

[0067] 3.5 g of soluble starch was weighed and dissolved in 100 mL of deionized aqueous solution with stirring to prepare a 3% solution, which was completely gelatinized in a 95° C. wa...

Embodiment 2

[0079] (1) Preparation of nanocrystalline cellulose

[0080] 9 g of MCC was dispersed in 50 mL of sulfuric acid with a mass fraction of 70%, vigorously mechanically stirred at 50° C. for 10 h, and the reaction mixture was diluted with 8 times of water to quench the hydrolysis reaction. Then 8 mL of 30 wt% H was added 2 O 2 solution, a suspension of oxidized nanocrystalline cellulose. After 30 min of reaction, the crystals were separated by centrifugation at 8000 rpm for 10 min, washed with ultrasonic waves, and centrifuged several times to remove excess acid. Finally, dialysis (molecular weight cut off 14000kDa) and freeze-drying were carried out to prepare nanocrystalline cellulose.

[0081] (2) Preparation of gelatinized soluble starch

[0082] 4 g of soluble starch was weighed and dissolved in 100 mL of deionized aqueous solution with stirring to prepare a 4% solution, which was completely gelatinized in a 95° C. water bath for 30 min, cooled to 80° C. for later use.

...

Embodiment 3

[0088] (1) Preparation of nanocrystalline cellulose

[0089] 7.5 g of MCC was dispersed in 50 mL of sulfuric acid with a mass fraction of 75%, vigorously mechanically stirred at 50° C. for 10 h, and the reaction mixture was diluted with 8 times of water to quench the hydrolysis reaction. Then 8 mL of 30 wt% H was added 2 O 2 solution, a suspension of oxidized nanocrystalline cellulose. After 30 min of reaction, the crystals were separated by centrifugation at 8000 rpm for 10 min, washed with ultrasonic waves, and centrifuged several times to remove excess acid. Finally, dialysis and freeze-drying were performed to prepare nanocrystalline cellulose.

[0090] (2) Preparation of gelatinized soluble starch

[0091] 3.5 g of soluble starch was weighed and dissolved in 100 mL of deionized aqueous solution with stirring to prepare a 5% solution, which was completely gelatinized in a 95° C. water bath for 30 minutes, cooled to 80° C. for later use.

[0092] (3) Preparation of hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com