Halogen-free flame-retardant scratch-resistant antibacterial polypropylene material as well as preparation method and application thereof

An antibacterial polypropylene and scratch-resistant technology, applied in the field of modified polypropylene materials and their preparation, can solve the problems of adding a large amount of flame retardant, harmful to human body, and adding a large amount of halogen-free flame retardant, so as to improve the resistance to Scratch effect, lower flame retardant dosage, effect of excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Preparation of Zirconium Phosphonate 1#

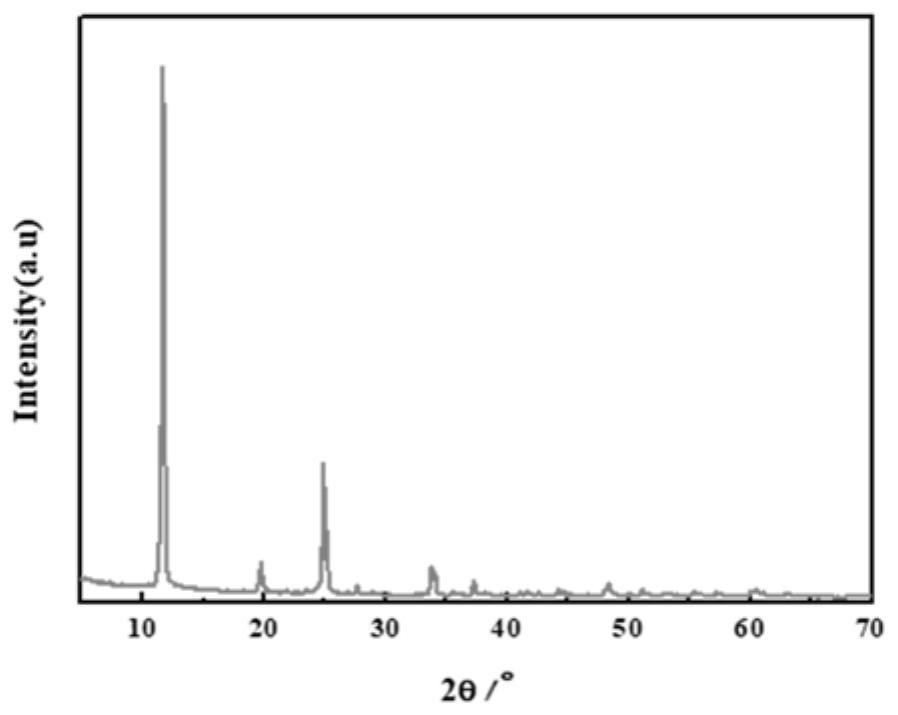

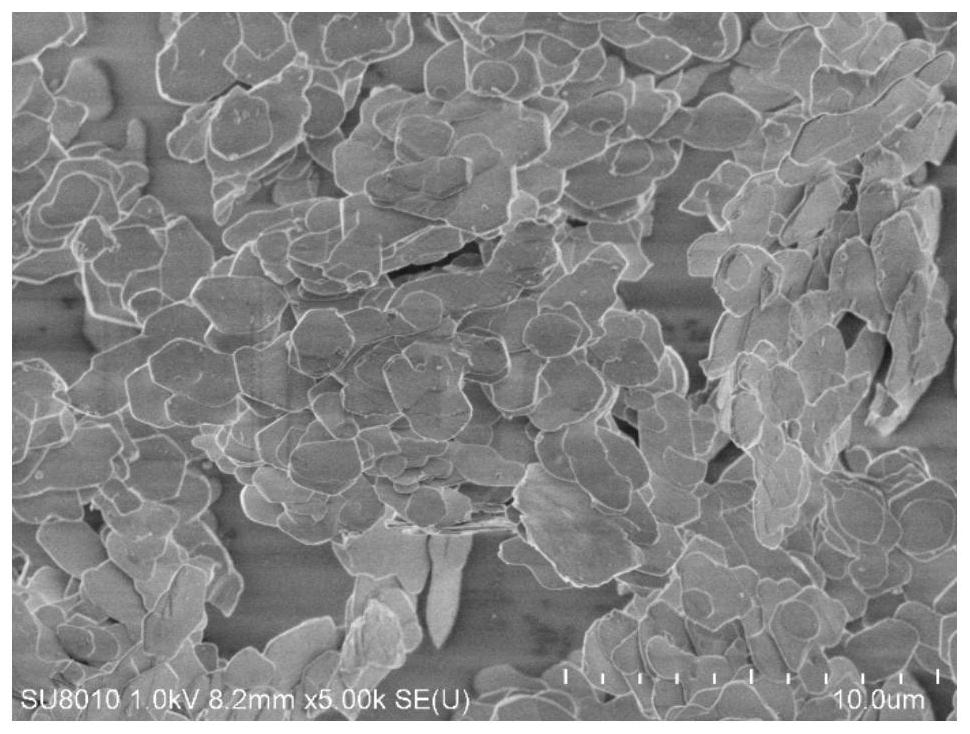

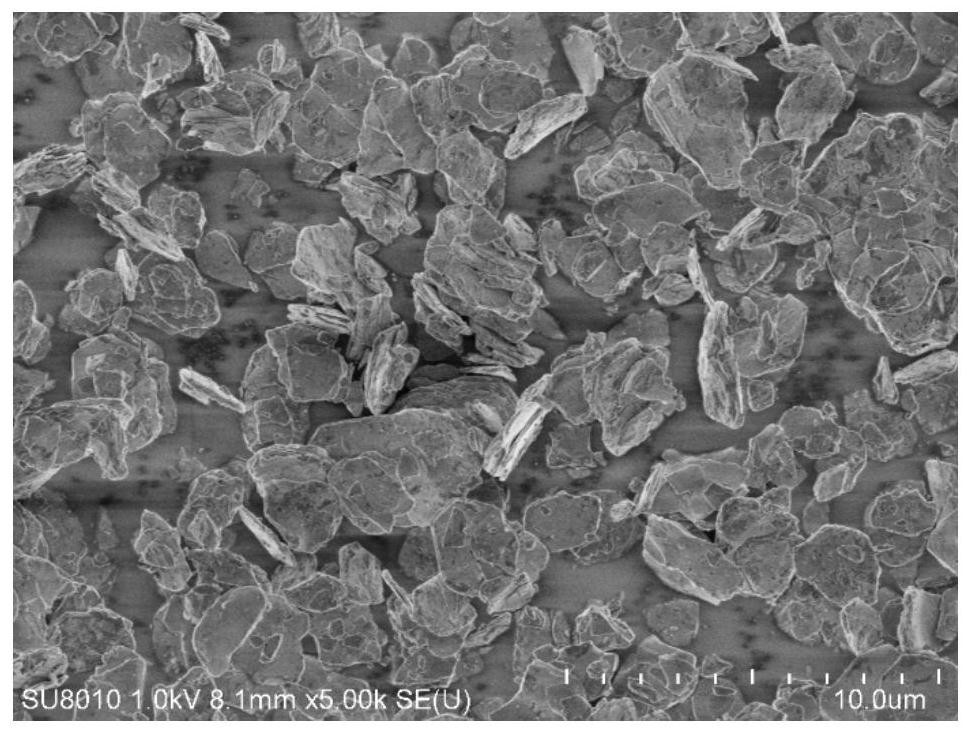

[0054] Accurately weigh 20.3g of zirconium oxychloride and dissolve it in 200mL of deionized water to make an aqueous solution of zirconium oxychloride, and accurately weigh 21g of glyphosate and dissolve it in 3000mL of deionized water to make an aqueous solution of glyphosate. Add 40 g of hydrofluoric acid with a concentration of 40% to the zirconium oxychloride aqueous solution, stir and mix the zirconium oxychloride aqueous solution and the glyphosate aqueous solution in a flask, keep stirring, heat the reaction in a water bath at 80° C. for 6 hours, centrifuge the product, and use Wash with deionized water until the supernatant is neutral, dry at 90°C, and grind the sample into powder to obtain 28.7 g of zirconium glyphosate phosphonate, which is denoted as ZrGP1, and its X-ray diffraction (XRD) spectrum is shown in figure 1 , the scanning electron microscope (SEM) photo see figure 2 .

[0055] Preparation of Silver Ammo...

Embodiment 1

[0062] 7 parts of intumescent flame retardant, 7 parts of silver ammonium phosphomolybdate intercalated zirconium phosphate, 4 parts of ceramic fiber powder, 2 parts of silicone masterbatch MB50-001 (Dow Corning), 0.8 parts of antioxidant 1010, 36 parts of white oil #0.5 parts and 78.5 parts of polypropylene 6012 (Sinopec) were weighed and mixed uniformly in proportion, then added to a twin-screw extruder with a length-to-diameter ratio of 38:1, melted, extruded and granulated to obtain the product. The product performance is shown in Table 2.

Embodiment 2

[0064] 9 parts of intumescent flame retardant, 3 parts of silver ammonium phosphomolybdate intercalated zirconium phosphate, 2 parts of ceramic fiber powder, 3 parts of silicone masterbatch MB50-001 (Dow Corning), 0.5 parts of antioxidant 1010, 36 parts of white oil #0.5 parts and 82 parts of polypropylene 6012 (Sinopec) were weighed and mixed uniformly in proportion, then added to a twin-screw extruder with a length-to-diameter ratio of 38:1, melted, extruded and granulated to obtain the product. Product properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com