Thermoplastic composite material bolt and preparation method and application thereof

A composite material, thermoplastic technology, applied in the field of rod bolts, to achieve the effect of easy promotion, excellent mechanical properties, and improved axial and radial rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

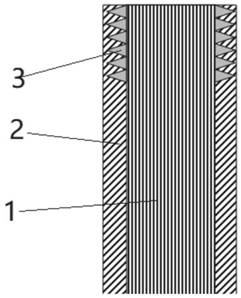

[0031] A thermoplastic composite bolt specifically includes two parts: a thermoplastic hybrid fiber reinforced core 1 and a surface thermoplastic hybrid fiber wound thread layer 2 . Among them, the thermoplastic hybrid fiber reinforced core 1 is reinforced by mixing M40 carbon fiber and aramid K129 fiber at a ratio of 4:1, and is composited with a polyethylene matrix with a resin content of 60%. The hybrid fiber is arranged in one direction by pultrusion. Extrusion process compound infiltration thermoplastic matrix to form a reinforced core 1 with a diameter of 6 mm. On the surface of the hybrid fiber reinforced core 1, T300 carbon fiber and aramid K29 fiber are mixed with a mixing ratio of 5:1, and the surface thread reinforcement layer 2 is prepared by a hoop winding method with a winding angle of 85°. After winding the fibers of the reinforced thread layer 2, the fibers of the thread layer are impregnated with polyethylene resin with a resin content of 50% at a temperatur...

Embodiment 2

[0033] A thermoplastic composite bolt specifically includes two parts: a thermoplastic hybrid fiber reinforced core 1 and a surface thermoplastic hybrid fiber wound thread layer 2 . Among them, the thermoplastic hybrid fiber reinforced core 1 is reinforced by mixing M60 carbon fiber and aramid K29 fiber at a ratio of 2:1, and is composited with a polypropylene matrix with a resin content of 65%. The hybrid fiber is unidirectionally arranged by pultrusion. Extrusion process compound infiltration thermoplastic matrix to form a reinforced core with a diameter of 4mm. T700 carbon fiber and UHMWPE fiber were mixed on the surface of the hybrid fiber reinforced core with a mixing ratio of 5:3, and the surface thread reinforcement layer 2 was prepared in a spiral winding manner with a winding angle of 45°. After winding the fibers of the reinforced thread layer 2, the fibers of the thread layer are impregnated with polyethylene resin with a resin content of 55% at a temperature of 2...

Embodiment 3

[0035] A thermoplastic composite bolt specifically includes two parts: a thermoplastic hybrid fiber reinforced core 1 and a surface thermoplastic hybrid fiber wound thread layer 2 . Among them, the thermoplastic hybrid fiber reinforced core 1 is reinforced by mixing M55 carbon fiber and aramid K129 fiber at a ratio of 2:1, and is compounded with an ethylene terephthalate matrix with a resin content of 50%, and the hybrid fiber is pultruded. Arranged vertically, the reinforced core 1 with a diameter of 2 mm is formed by compositely infiltrating a thermoplastic matrix by a pultrusion process. The surface of the hybrid fiber reinforced core 1 is mixed with T800 carbon fiber and PBO fiber with a mixing ratio of 3:1, and the surface thread reinforcement layer 2 is prepared by a hoop winding method with a winding angle of 88°. After winding the fibers of the reinforced thread layer 2, the fibers of the thread layer are impregnated with polyethylene resin with a resin content of 65% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com