Reusable biodegradable plastic and preparation method thereof

A technology of biodegradable plastics and raw materials, applied in the field of biodegradable plastics and its preparation, can solve the problems of insufficient material hardness and temperature resistance, lack of toughness and rigidity, low comprehensive performance of plastics, etc., achieve low cost, accelerate plastic degradation, Effect of improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

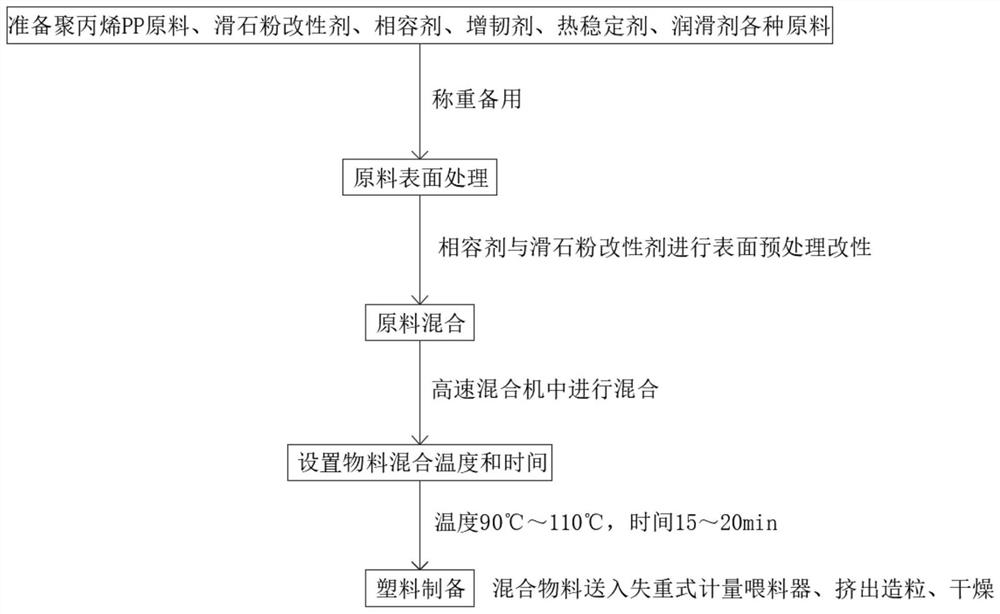

Method used

Image

Examples

Embodiment 1

[0037] A recyclable biodegradable plastic, in weight percentage, comprising the following components:

[0038] 65wt% polypropylene PP raw material, 32wt% talc modifier, 1.0wt% compatibilizer, 1.5wt% toughening agent, 0.2wt% heat stabilizer, 0.3wt% lubricant.

[0039] Specifically, the talc modifier is selected from at least one particle size of 1250 mesh, 2000 mesh, 3000 mesh, 5000 mesh, and 20-100 nm.

[0040] The rigidity of polypropylene PP raw materials is improved by talc mineral inorganic ion polymerization technology, the flexural modulus reaches more than 3000 MPa, and the flexural strength reaches more than 37 MPa. The talc powder is unstable to light to accelerate the degradation of PP materials.

[0041] Specifically, the compatibilizer is selected from POE-g-MAH, SEBS-g-MAH, PP-g-MAH, silane coupling agent, titanate coupling agent, aluminate coupling agent, composite coupling agent at least one of the agents.

[0042] The main function of setting the compatibiliz...

Embodiment 2

[0056] A recyclable biodegradable plastic, in weight percentage, comprising the following components:

[0057] 50wt% polypropylene PP raw material, 38.5wt% talc modifier, 5.0wt% compatibilizer, 5.0wt% toughening agent, 0.5wt% heat stabilizer, 1.0wt% lubricant.

[0058] Specifically, the talc modifier is selected from at least two of the particle sizes of 1250 mesh, 2000 mesh, 3000 mesh, 5000 mesh, and 20-100 nm.

[0059] The rigidity of polypropylene PP raw materials is improved by talc mineral inorganic ion polymerization technology, the flexural modulus reaches more than 3000 MPa, and the flexural strength reaches more than 37 MPa. The talc powder is unstable to light to accelerate the degradation of PP materials.

[0060] Specifically, the compatibilizer is selected from POE-g-MAH, SEBS-g-MAH, PP-g-MAH, silane coupling agent, titanate coupling agent, aluminate coupling agent, composite coupling agent at least two of the agents.

[0061] The main function of setting the co...

Embodiment 3

[0075] A recyclable biodegradable plastic, in weight percentage, comprising the following components:

[0076] 58wt% polypropylene PP raw material, 35wt% talc modifier, 3.0wt% compatibilizer, 3.0wt% toughening agent, 0.35wt% heat stabilizer, 0.65wt% lubricant.

[0077] Specifically, the talc modifier is selected from at least one particle size of 1250 mesh, 2000 mesh, 3000 mesh, 5000 mesh, and 20-100 nm.

[0078] The rigidity of polypropylene PP raw materials is improved by talc mineral inorganic ion polymerization technology, the flexural modulus reaches more than 3000 MPa, and the flexural strength reaches more than 37 MPa. The talc powder is unstable to light to accelerate the degradation of PP materials.

[0079] Specifically, the compatibilizer is selected from POE-g-MAH, SEBS-g-MAH, PP-g-MAH, silane coupling agent, titanate coupling agent, aluminate coupling agent, composite coupling agent at least two of the agents.

[0080] The main function of setting the compatibil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com