Preparation method of carbon black nano material

A nanomaterial and carbon black technology, applied in the field of nanomaterials, can solve the problems of affecting reinforcement performance, decreased bacteriostatic effect, poor bacteriostatic effect, etc., and achieve improved mechanical properties and bacteriostatic performance, good dispersibility and bacteriostatic performance. , the effect of strong fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

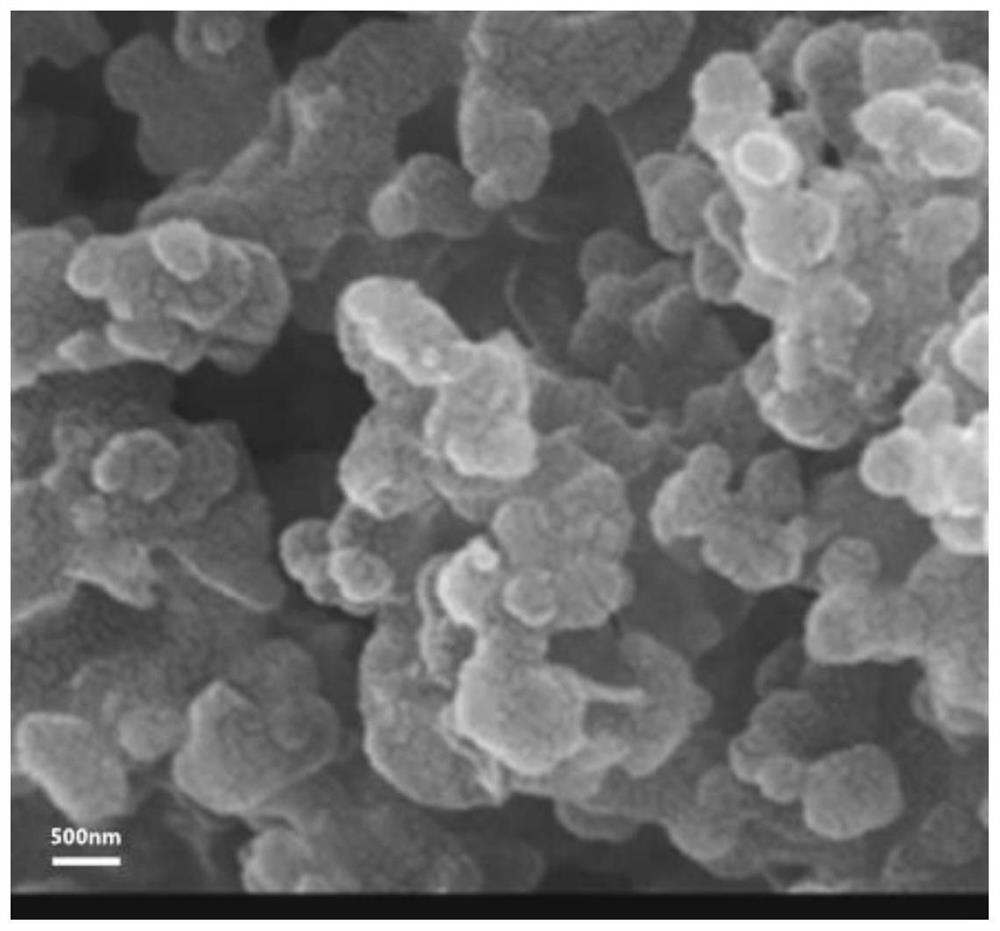

[0038] A preparation method of carbon black nanomaterial, comprising the following steps:

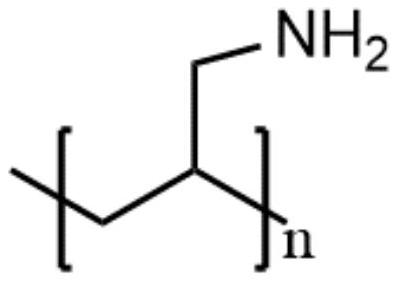

[0039] Step 1. Weigh nano carbon black with model Vulcan XC-72 and particle size of 600-800 nm and disperse it in a NaOH solution with a mass fraction of 5% by ultrasonic dispersion. The mass ratio of nano carbon black to NaOH solution is 1:15. Stir for 3 hours at 55°C, and the filter residue obtained by filtration under reduced pressure is washed with pure water until the washing solution is neutral, and then vacuum dried to obtain activated nano-carbon black;

[0040] Step 2. Dissolve polyallylamine in absolute ethanol, the mass ratio of polyallylamine to absolute ethanol is 1.4:25, slowly add activated nano-carbon black, activated nano-carbon black and polyallylamine The mass ratio of 1:0.28, stirred at room temperature for 10h, and vacuum-dried the filter residue obtained by filtration under reduced pressure to obtain polyallylamine / nano carbon black;

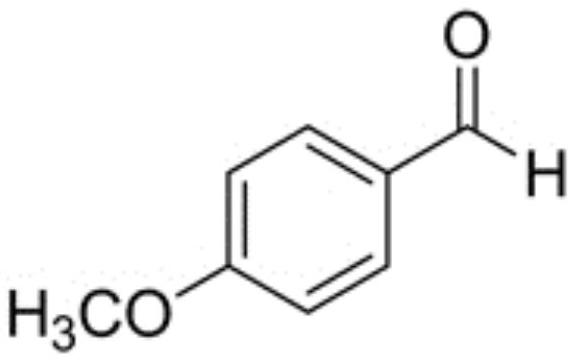

[0041] Step 3, taking by wei...

Embodiment 2

[0044] A preparation method of carbon black nanomaterial, comprising the following steps:

[0045] Step 1. Weigh the nano-carbon black with a model of Vulcan XC-72 and a particle size of 600-800 nm and ultrasonically disperse it in a KOH solution with a mass fraction of 5%. The mass ratio of the nano-carbon black to the KOH solution is 1:10. Stir for 2 hours at 50-60°C, and the filter residue obtained by filtration under reduced pressure is washed with pure water until the washing solution is neutral, and then vacuum dried to obtain activated nano-carbon black;

[0046] Step 2. Dissolve polyallylamine in absolute ethanol, the mass ratio of polyallylamine to absolute ethanol is 1.2:20, slowly add activated nano-carbon black, activated nano-carbon black and polyallylamine The mass ratio is 1:0.22, stirred at room temperature for 8h, and the filter residue obtained by filtration under reduced pressure is vacuum-dried to obtain polyallylamine / nano carbon black;

[0047] Step 3, t...

Embodiment 3

[0050] A preparation method of carbon black nanomaterial, comprising the following steps:

[0051] Step 1. Weigh the nano-carbon black with a model of Vulcan XC-72 and a particle size of 600-800 nm and disperse it in ammonia water with a mass fraction of 10% by ultrasonic. The mass ratio of nano-carbon black and ammonia water is 1:20. Under stirring for 4 hours, the filter residue obtained by filtration under reduced pressure is washed with pure water until the washing solution is neutral, and then vacuum dried to obtain activated nano-carbon black;

[0052] Step 2. Dissolve polyallylamine in absolute ethanol, the mass ratio of polyallylamine to absolute ethanol is 1.6:30, slowly add activated nano-carbon black, activated nano-carbon black and polyallylamine The mass ratio of the powder was 1:0.35, stirred at room temperature for 12 h, and vacuum-dried the filter residue obtained by filtration to obtain polyallylamine / nano carbon black;

[0053] Step 3, taking by weighing p-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com