Treatment method suitable for highlight mirror surface plastic uptake door plate

A treatment method and door panel technology, applied in spray booths, spraying devices, etc., can solve problems such as uneven pits, surface effects that are difficult to meet the needs of end customers, and poor hand feeling, and achieve low surface pits and scratches, and are convenient The effect of the sanding and gluing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

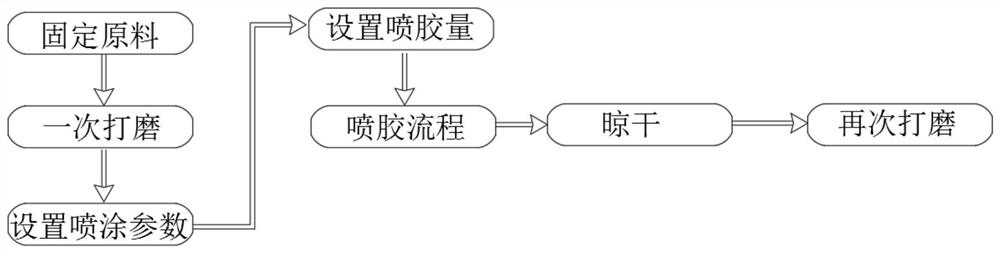

[0028] refer to figure 1 , suitable for the processing method of high-gloss mirror blister door panels, including the following steps:

[0029] S1: Fix the raw material, fix the plate to be processed on the rotatable worktable, and debug it so that it can be rotated and fixed normally, which is convenient for the grinding and gluing steps of the plate, saving time and effort;

[0030] S2: Grind once. Before spraying glue, use sponge cubes and different specifications of sandpaper to polish in four steps. When grinding: The first step is to use sponge cube sand and 320-grit sandpaper to polish the modeling part until the roughness is uniform and there are no obvious knife marks. , the second step is to use sponge square sand and 180-grit sandpaper to polish the wire groove until the surface is smooth and free of fiber burrs. Grind the surface with grit sandpaper until the surface is smooth, free of fiber burrs and sand marks;

[0031] S3: Set the spraying parameters, use the ...

Embodiment 2

[0037] refer to figure 1 , suitable for the processing method of high-gloss mirror blister door panels, including the following steps:

[0038] S1: Fix the raw material, fix the plate to be processed on the rotatable worktable, and debug it so that it can be rotated and fixed normally, which is convenient for the grinding and gluing steps of the plate, saving time and effort;

[0039] S2: Grind once. Before spraying glue, use sponge cubes and different specifications of sandpaper to polish in four steps. When grinding: The first step is to use sponge cube sand and 320-grit sandpaper to polish the modeling part until the roughness is uniform and there are no obvious knife marks. , the second step is to use sponge square sand and 180-grit sandpaper to polish the wire groove until the surface is smooth and free of fiber burrs. Grind the surface with grit sandpaper until the surface is smooth, free of fiber burrs and sand marks;

[0040] S3: Set the spraying parameters, use the ...

Embodiment 3

[0046] refer to figure 1 , suitable for the processing method of high-gloss mirror blister door panels, including the following steps:

[0047] S1: Fix the raw material, fix the plate to be processed on the rotatable worktable, and debug it so that it can be rotated and fixed normally, which is convenient for the grinding and gluing steps of the plate, saving time and effort;

[0048] S2: Grind once. Before spraying glue, use sponge cubes and different specifications of sandpaper to polish in four steps. When grinding: The first step is to use sponge cube sand and 320-grit sandpaper to polish the modeling part until the roughness is uniform and there are no obvious knife marks. , the second step is to use sponge square sand and 180-grit sandpaper to polish the wire groove until the surface is smooth and free of fiber burrs. Grind the surface with grit sandpaper until the surface is smooth, free of fiber burrs and sand marks;

[0049] S3: Set the spraying parameters, use the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com