Double-component glue automatic glue mixer

A technology of two-component glue and glue mixing machine, which is applied in mixers, mixers with rotating stirring devices, mixing methods, etc., and can solve the problems of not being suitable for high-speed automatic production, low production efficiency, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawings and examples.

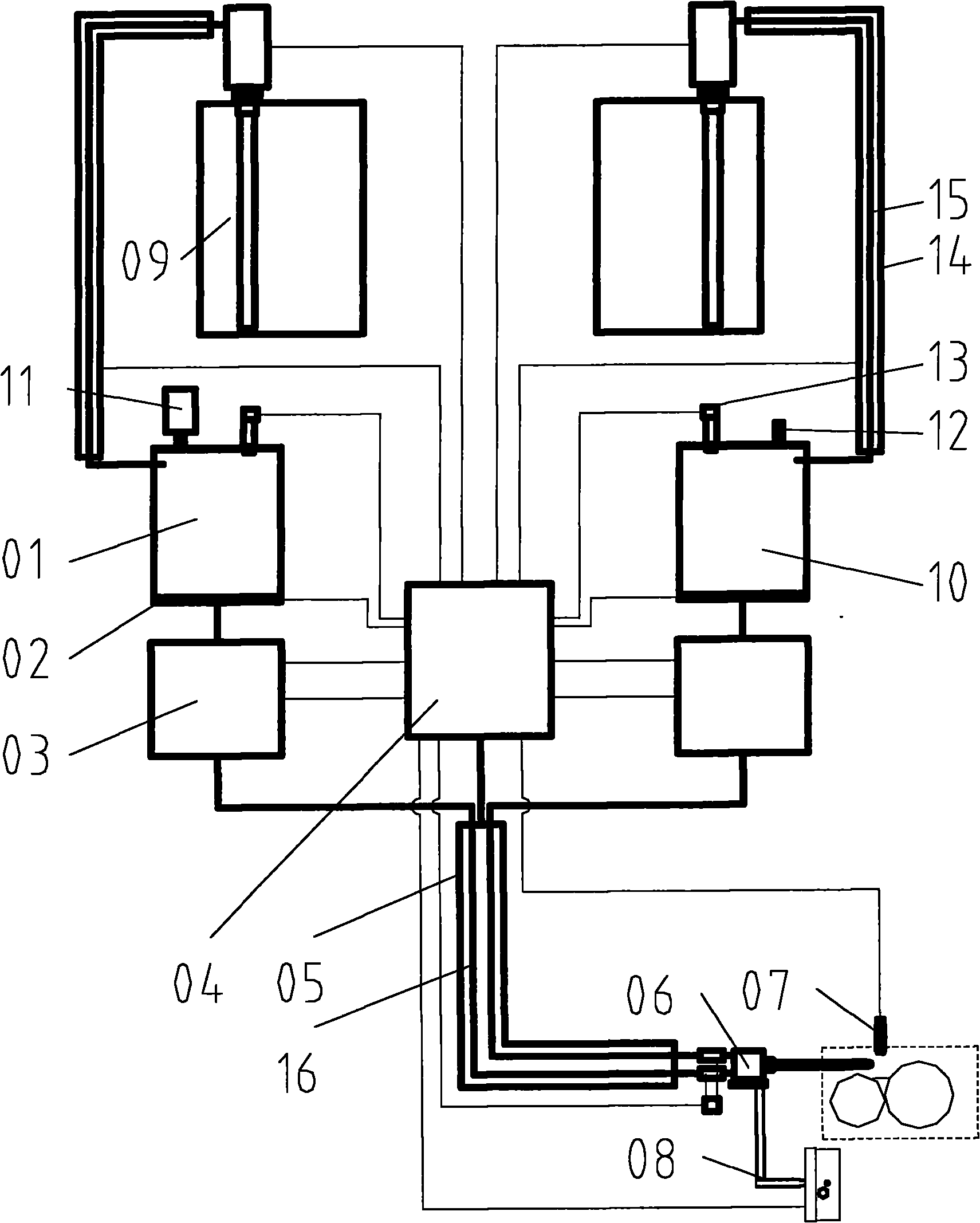

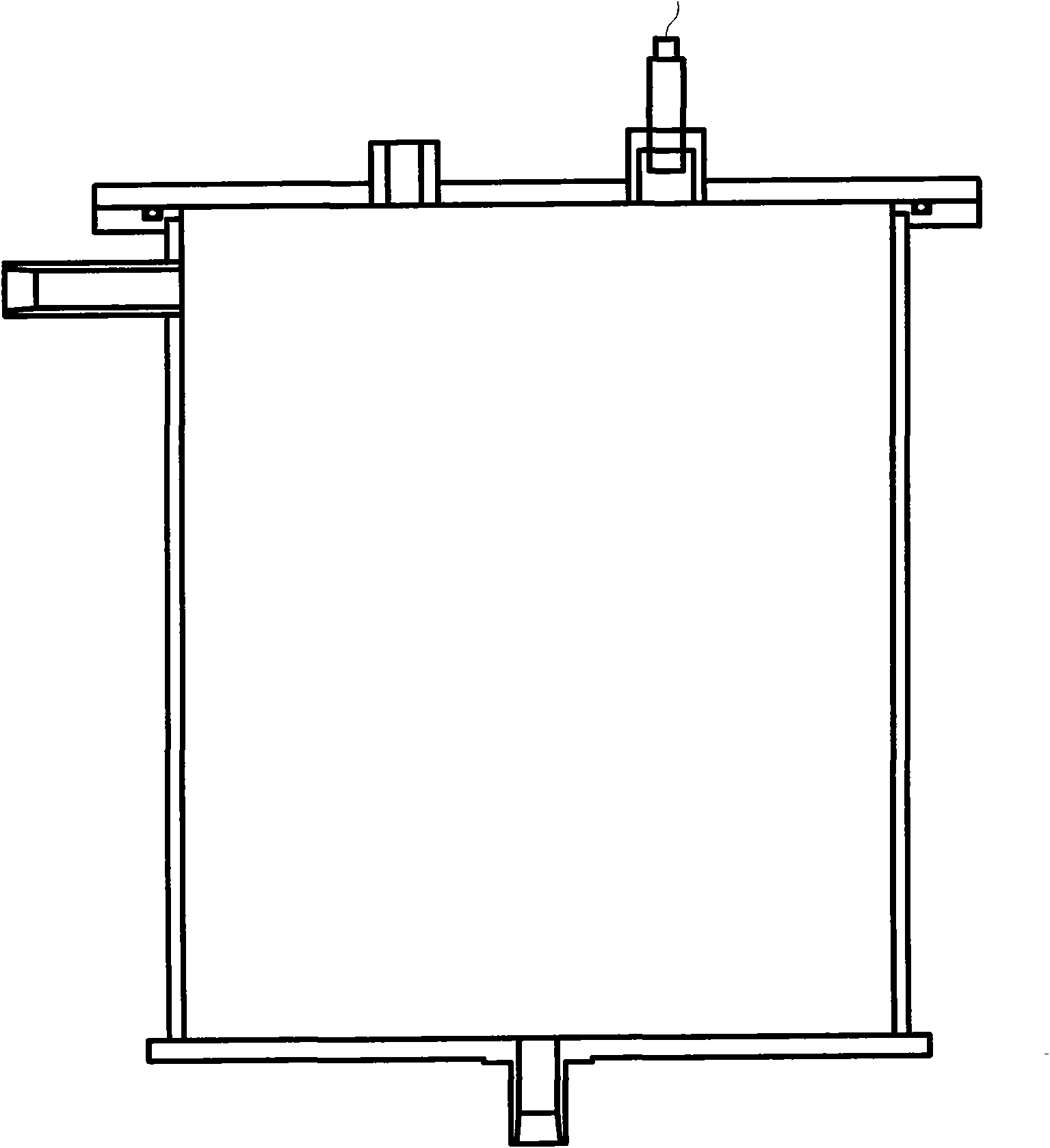

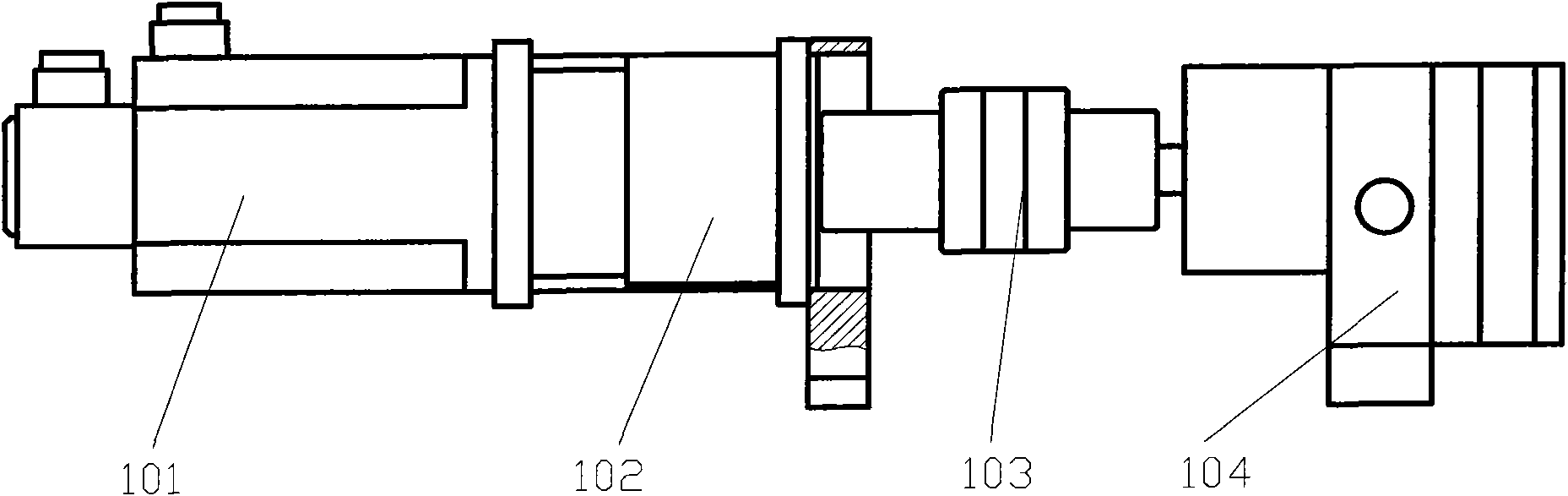

[0020] Please refer to the accompanying drawings. In this invention, the A and B glues that need to be mixed are placed in the A glue storage bucket 01 and the B glue storage bucket 10 respectively. When the glue needs to be waterproof, the air intake of the double glue storage bucket A dryer can be installed at the mouth. Under the control of the electric control system, the glue storage barrel heating ring 02 in contact with the bottom of the barrel heats the glue in the glue storage barrel to the required temperature, and through the electric control system 04, the motor 101 of the output mechanism drives the gear pump at a certain speed 103 operation, A and B glues pass through gear pump 104, rubber pipe 16, pneumatic actuator 201 from glue storage tanks 01 and 10 respectively in proportion, and enter into mixing head 202, and the rod core in mixing pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com