Machining and positioning tool for side face hole of slewing bearing

A technology of slewing bearing and positioning tooling, which is applied in positioning devices, supports, metal processing equipment, etc., can solve the problems of clogging and reserved groove cleaning, low processing efficiency of slewing bearings, low continuous operation efficiency, etc. The convenience of clearing blockage, avoiding too long cleaning time, and reducing the effect of post-processing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

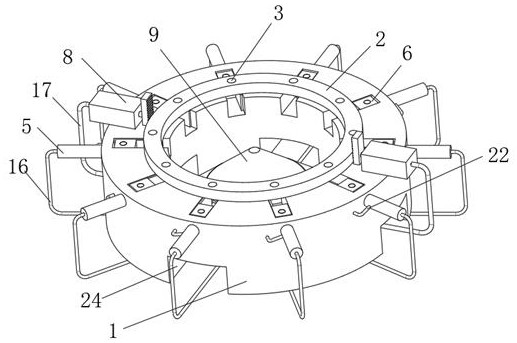

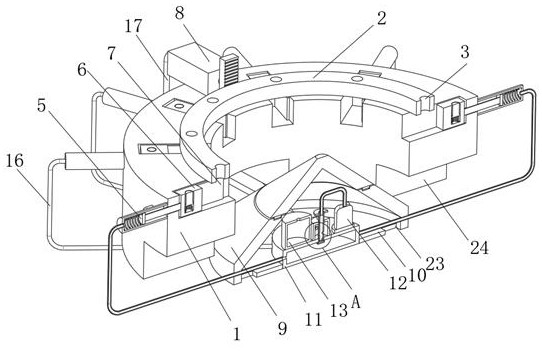

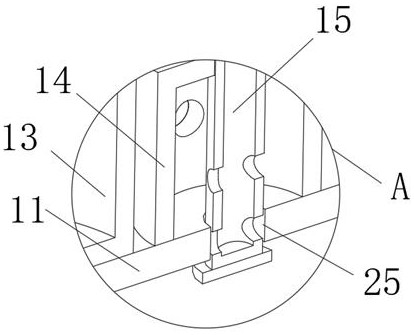

[0022] The first embodiment: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the slewing bearing 2 is placed on the top surface of the mounting base 1, and the hydraulic pump 12 is started. As the hydraulic pump 12 enters the No. 2 distribution sleeve 14, the internal oil pressure of the No. 2 distribution sleeve 14 increases, so that the The pressure oil enters the positioning mechanism 8 through the No. 2 pipe 17, and the positioning mechanisms 8 on both sides act simultaneously, so that the slewing bearing is fixedly clamped between the two sets of positioning mechanisms 8. After the drilling is completed, the telescopic rod 20 is activated to make the telescopic The rod 20 pushes the adjustment mechanism 15 down, so that the No. 2 hole 155 on the adjustment mechanism 15 moves down from the through hole 25 to the inside of the No. 1 distribution sleeve 11. At this time, the hydraulic pump 12 simultaneously supplies the No. 1 distribution sleeve 11 ...

no. 2 example

[0034] Second embodiment: as figure 1 , figure 2 , Figure 4 and Figure 10 As shown, during the continuous machining of large batches of slewing bearings, as the drilling arm drills along the top surface of the slewing bearing 2, a large amount of scrap is sputtered out and falls on the outer surface of the guide mechanism 9, and with the large amount of cutting When the liquid is ejected, part of the cutting fluid flows into the outer surface of the guide mechanism 9 , and the cutting along the inclined downward flow of the guide mechanism 9 flows down with the falling scrap, and the cutting fluid mixed with the scrap flows into the mounting seat 1 through the guide mechanism 9 In the side groove 24, and with the continuous drilling work, the cutting fluid used in large quantities and sprayed continuously slides down to the side groove 24 along the guide mechanism 9, and the cutting fluid flowing down from a high place by gravity at this time is The bottom gathers into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com