High-hydrocarbon liquid fuel reforming hydrogen production catalyst as well as preparation method and application thereof

A liquid fuel, reforming hydrogen production technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of easy carbonization, activity and high temperature resistance , easy sulfur poisoning and other problems, to achieve the effect of rapid reaction, inhibition of carbon sintering phenomenon, and high degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

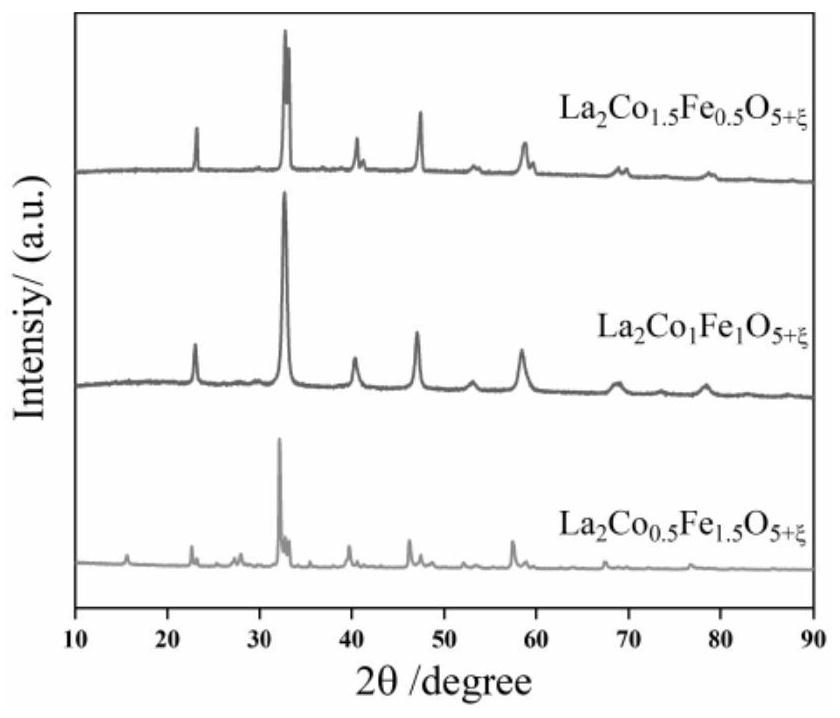

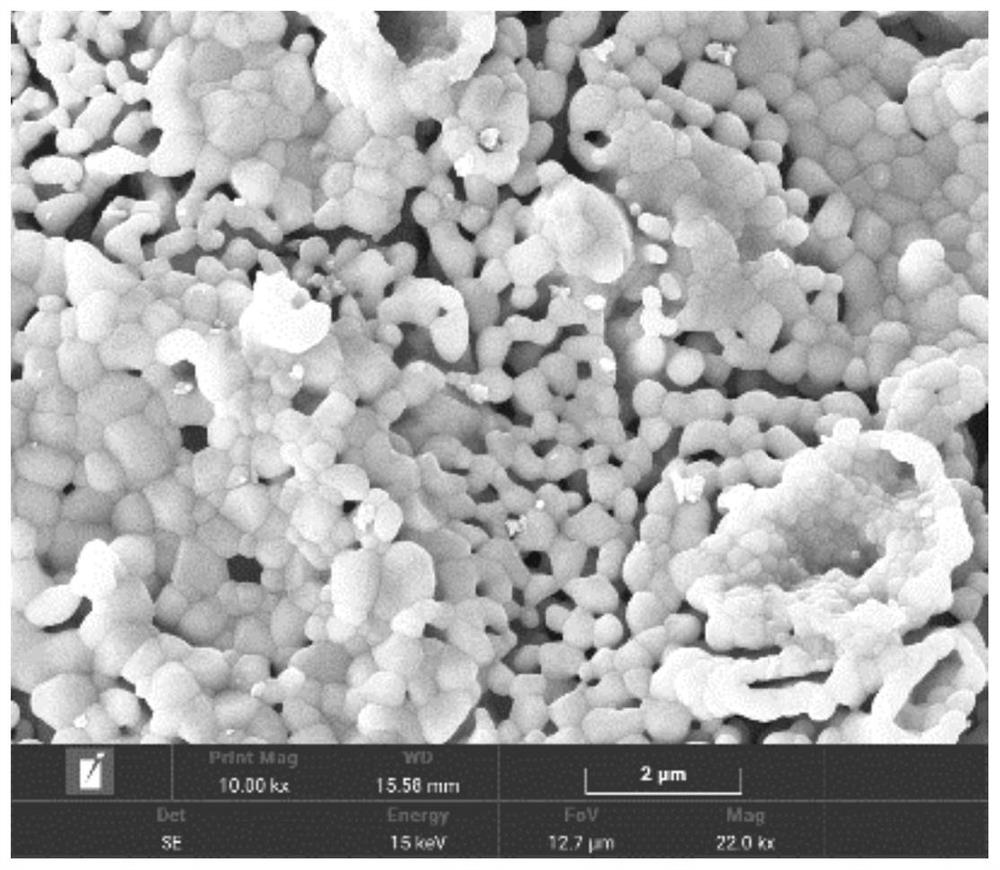

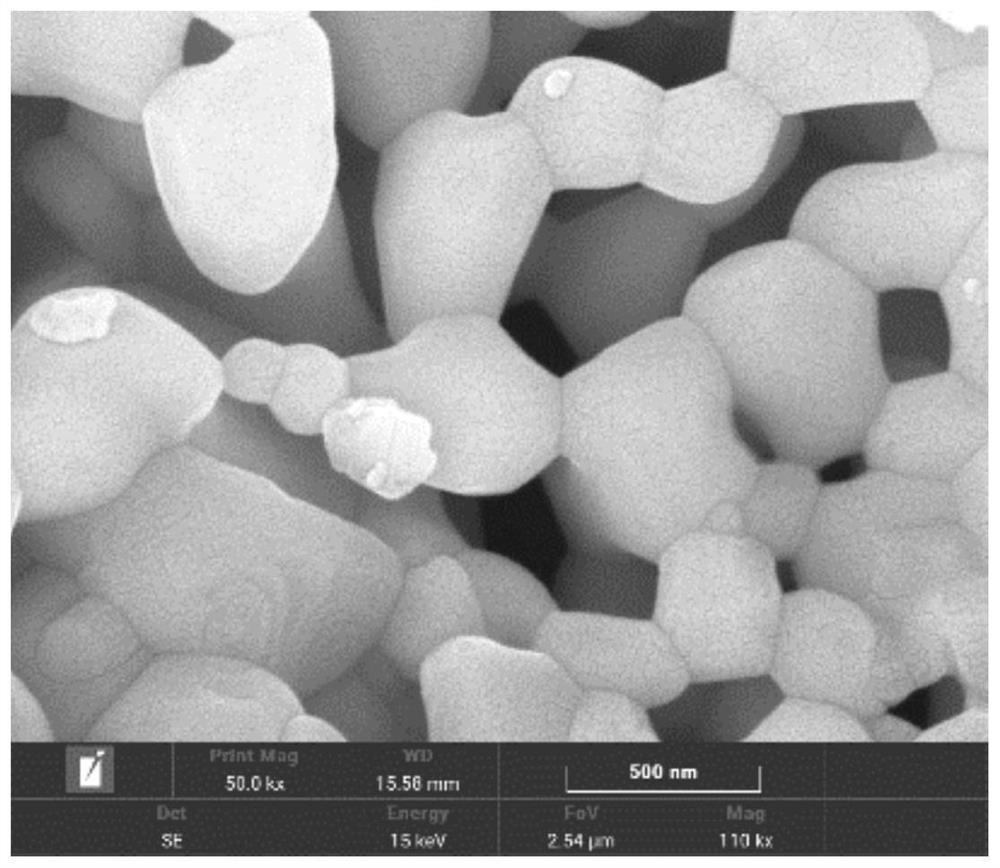

Embodiment 1

[0046] B1. On a molar basis, dissolve 2 parts of lanthanum nitrate, 0.5 part of cobalt nitrate and 1.5 parts of ferric nitrate in distilled water in sequence under magnetic stirring until the mixture is uniform to form a clear and transparent solution.

[0047] B2. Add 1 part of acetylacetone and 2 parts of acetic acid to 1 part of hexamethylenetetramine in turn under the condition of oil bath heating, and after stirring, obtain a light yellow viscous liquid, and configure to obtain a complexing agent.

[0048] B3. Add 1 part of the prepared complexing agent to 1 part of the clear and transparent solution obtained from B1 and heat it in an oil bath, the heating temperature is 80°C, the heating time of the oil bath heating is 2h, and the preparation is carried out under magnetic stirring into a gel.

[0049] B4. Place the above gel in an oven to dry, the drying temperature is 180°C, and the drying time is 3h;

[0050] B5. Grind the dried gel into powder, calcined at 1000°C, th...

Embodiment 2

[0054] C1. On a molar basis, 2 parts of lanthanum nitrate, 1 part of cobalt nitrate and 1 part of ferric nitrate are sequentially dissolved in distilled water under the condition of magnetic stirring until the mixture is uniform to form a clear and transparent solution.

[0055] C2. Add 2 parts of acetylacetone and 5 parts of acetic acid to 2 parts of hexamethylenetetramine successively under the condition of oil bath heating, and after stirring, obtain a light yellow viscous liquid, and configure to obtain a complexing agent.

[0056] C3. Add 1 part of the prepared complexing agent to 1 part of the clear and transparent solution obtained from C1 and heat it in an oil bath, the heating temperature is 80°C, the heating time of the oil bath heating is 1h, and the preparation is carried out under magnetic stirring into a gel.

[0057] C4. Place the above gel in an oven to dry, the drying temperature is 180°C, and the drying time is 3h;

[0058] C5. Grind the dried gel into powde...

Embodiment 3

[0062] The molar ratio of lanthanum nitrate, cobalt nitrate and iron nitrate is 2:1.5:0.5,

[0063] D1. Dissolve 2 parts of lanthanum nitrate, 1.5 parts of cobalt nitrate and 0.5 part of ferric nitrate in distilled water successively under the condition of magnetic stirring on a molar basis until the mixture is uniform to form a clear and transparent solution.

[0064] D2. Add 1 part of 2,2-diethoxyacetophenone and 2 parts of acetic acid to 1 part of hexamethylenetetramine in turn under the condition of heating in an oil bath, stir to obtain a light yellow viscous liquid, and configure to obtain a complex mixture.

[0065] D3. Add 1 part of the prepared complexing agent to 1 part of the clear and transparent solution obtained in D1 and heat it in an oil bath, the heating temperature is 80°C, the heating time of the oil bath heating is 2h, and the preparation is carried out under magnetic stirring into a gel.

[0066] D4. Place the above gel in an oven to dry, the drying temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com