Non-closed overlying strata grouting filling isolation method

A non-closed, rock-covering technology, which is applied in the direction of filling, earth square drilling, surface mining, etc., can solve the problems of high cost of modified filling, waste of filling materials, and high cost of slurry material modification, so as to ensure the effect of grouting filling , reduce waste, and reduce filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

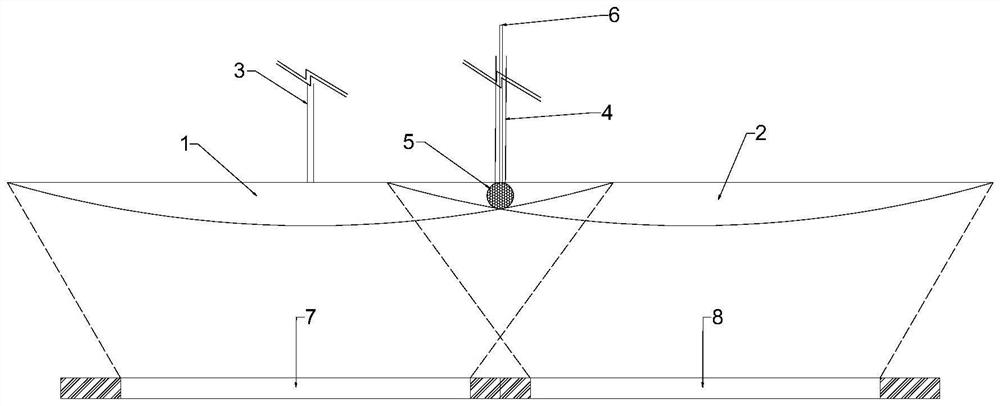

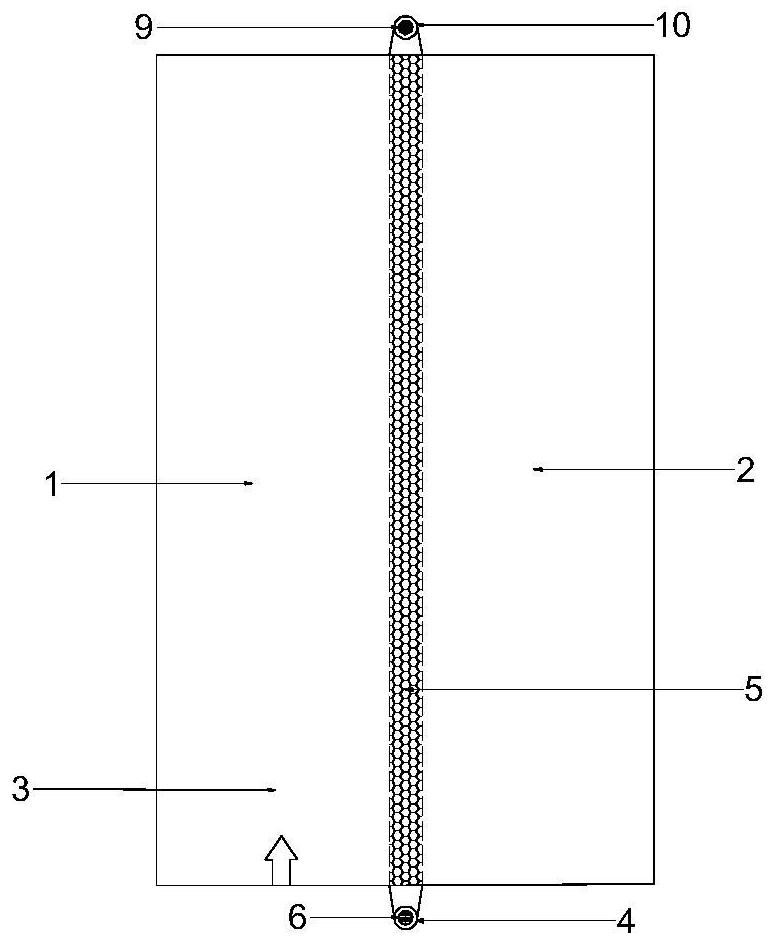

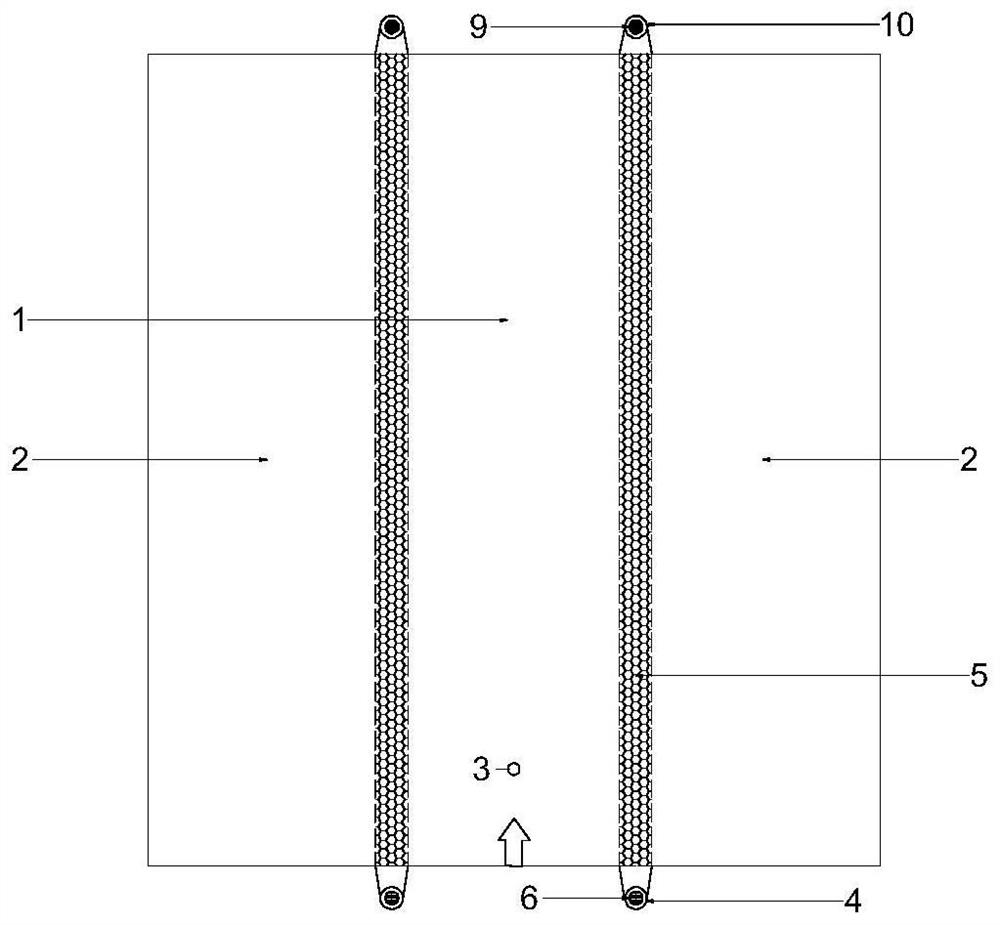

[0026] Such as Figure 1-2 As shown, the non-closed overlying rock grouting filling and isolation method of the present invention comprises the following steps:

[0027] a. Determine the lithology of the overlying rock according to the columnar shape of the drilled hole in the mining area, and judge the development position of the main mining fracture in the overlying rock based on this. The position where the main mining fracture develops is the grouting filling layer, such as figure 1 Mining fracture space 1 in the overlying rock and residual mining fracture 2 in the goaf side;

[0028] Preferably, in step a, a vertical borehole may be constructed above the mined working face 8 to detect the development position of the main mining fracture.

[0029] b. On the adjacent goaf side of the grouting filling working face 7 and at a certain distance outside the cut hole, a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com