Preparation method of C.I. Pigment yellow 83

A technology of pigment yellow and hydrochloric acid, applied in the field of pigment yellow, can solve the problems of different performance of dye products, different chromophores, different shades, etc., and achieve the effect of product dispersibility, uniform particle size distribution, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

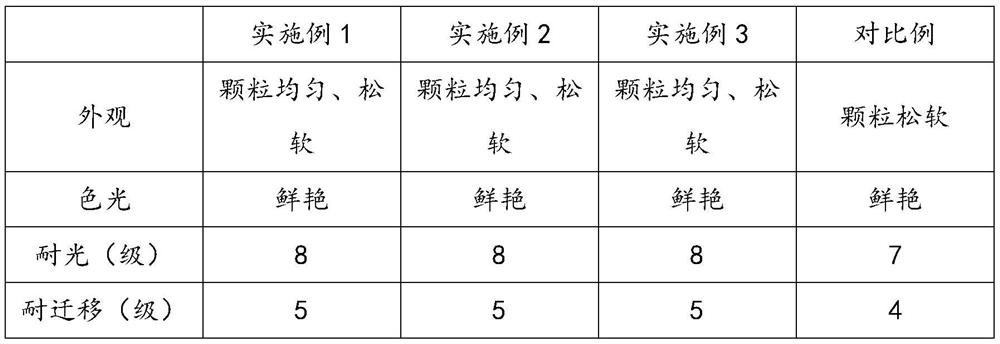

Examples

Embodiment 1

[0019] A preparation method of C.I. Pigment Yellow 83, comprising the steps:

[0020] Step 1, adding hydrochloric acid to the water and stirring evenly, then adding 3,3'-dichlorobenzidine and beating at room temperature for 20-40min to obtain 3,3'-dichlorobenzidine slurry for use; the hydrochloric acid adopts 30% hydrochloric acid , and the mol ratio of hydrochloric acid and 3,3'-dichlorobenzidine is 1:1, and the mass ratio of described water and hydrochloric acid is 2:1;

[0021] Step 2, adding hydrochloric acid to the water and stirring evenly, then adding 3,3'-dimethoxybenzidine and beating at room temperature for 20 minutes to obtain a 3,3'-dimethoxybenzidine slurry for use; the hydrochloric acid is 30% The hydrochloric acid, and the mol ratio of hydrochloric acid and 3,3'-dimethoxybenzidine is 1.5:1, and the mass ratio of described water and hydrochloric acid is 2:1;

[0022] Step 3, stir water and sodium nitrite evenly to form a nitrous acid solution, and the mass ratio...

Embodiment 2

[0027] A preparation method of C.I. Pigment Yellow 83, comprising the steps:

[0028] Step 1, adding hydrochloric acid to the water and stirring evenly, then adding 3,3'-dichlorobenzidine and beating at room temperature for 40min to obtain 3,3'-dichlorobenzidine slurry, which is for later use; the hydrochloric acid is 30% hydrochloric acid, and The mol ratio of hydrochloric acid and 3,3'-dichlorobenzidine is 1.1:1, and the mass ratio of described water and hydrochloric acid is 3:1;

[0029] Step 2, adding hydrochloric acid to the water and stirring evenly, then adding 3,3'-dimethoxybenzidine and beating at room temperature for 40 minutes to obtain 3,3'-dimethoxybenzidine slurry for use; the hydrochloric acid is 30% The hydrochloric acid, and the mol ratio of hydrochloric acid and 3,3'-dimethoxybenzidine is 1.8:1, and the mass ratio of described water and hydrochloric acid is 3:1;

[0030] Step 3, stir water and sodium nitrite to form a nitrous acid solution, and the mass rati...

Embodiment 3

[0035] A preparation method of C.I. Pigment Yellow 83, comprising the steps:

[0036] Step 1, adding hydrochloric acid to the water and stirring evenly, then adding 3,3'-dichlorobenzidine and beating at room temperature for 30 minutes to obtain 3,3'-dichlorobenzidine slurry, which is for later use; the hydrochloric acid is 30% hydrochloric acid, and The mol ratio of hydrochloric acid and 3,3'-dichlorobenzidine is 1:1, and the mass ratio of described water and hydrochloric acid is 2:1;

[0037] Step 2, adding hydrochloric acid to the water and stirring evenly, then adding 3,3'-dimethoxybenzidine and beating at room temperature for 30 minutes to obtain 3,3'-dimethoxybenzidine slurry for use; the hydrochloric acid is 30% The hydrochloric acid, and the mol ratio of hydrochloric acid and 3,3'-dimethoxybenzidine is 1.6:1, and the mass ratio of described water and hydrochloric acid is 2:1;

[0038] Step 3, stir water and sodium nitrite evenly to form a nitrous acid solution, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com