Method for preparing graphene by using waste graphite electrodes

A technology for discarding graphite and graphene, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of failing to fully utilize the economic value of graphite electrodes, low economic added value of products, and complicated processing processes, and achieve good results. Economic value and social value, the effect of less filling and larger specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

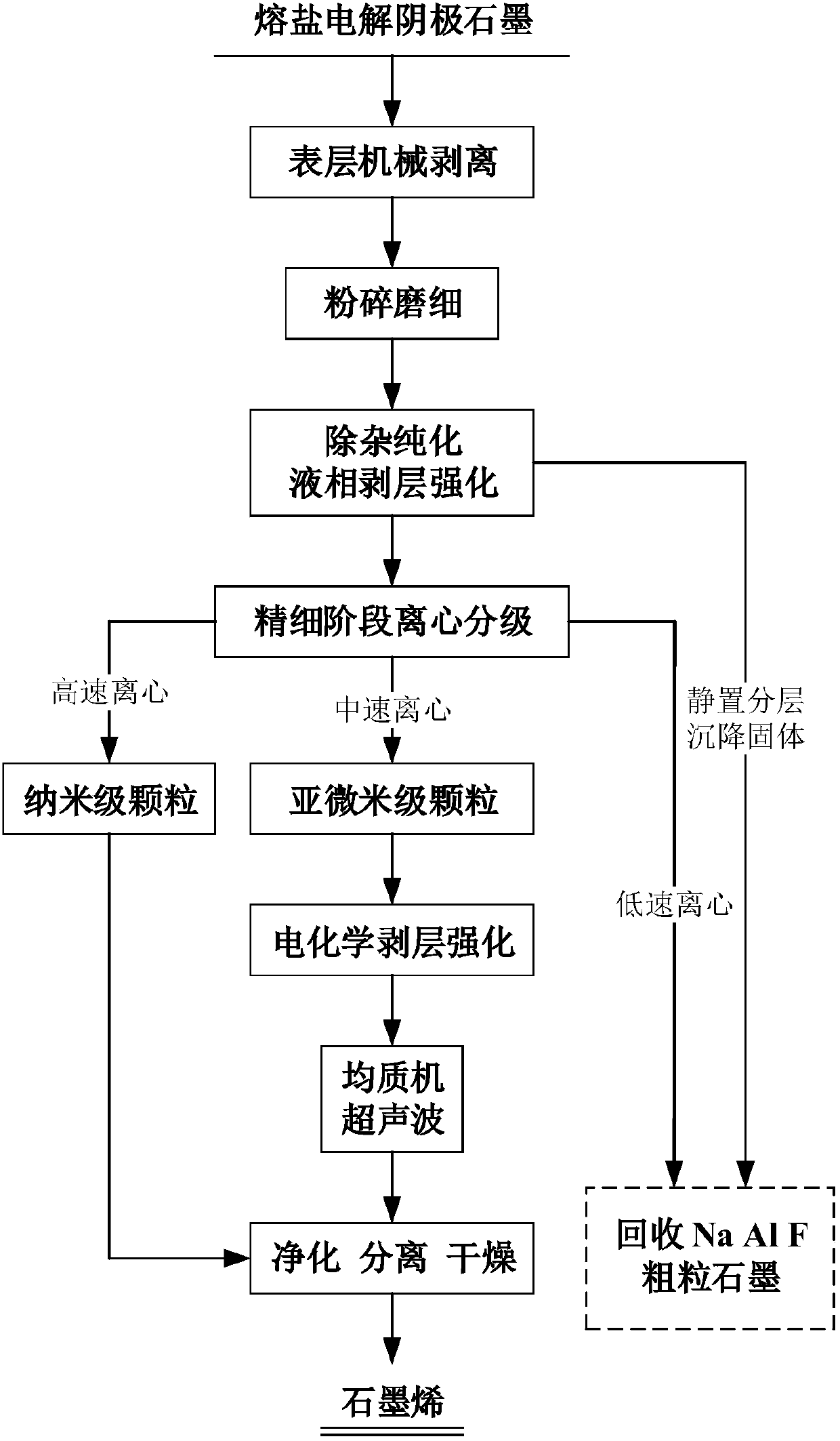

Image

Examples

Embodiment 1

[0051] First, at room temperature, LiF-Na 3 AlF 6 -KF as the raw material, molten salt electrolysis of aluminum produced waste cathode graphite electrode surface mechanically peeled off 0.5cm thick intercalated graphite block, and used ball mill equipment to crush into 20μm graphite powder; the graphite powder is placed in the liquid phase containing aluminum chloride In the purification stripping solution, hydrochloric acid is used to control the pH value to 1.0, the mass ratio of graphite powder to liquid phase purification stripping solution is 1:100, the weight ratio of aluminum chloride to graphite powder is 1:2, and the temperature is 50°C Stir for 0.5h, stand still for separation after stratification, obtain a turbid solution containing graphene in the upper layer for use, and impurities in the lower layer containing coarse graphite particles as raw materials for the recovery of coarse graphite and sodium, aluminum, and fluorine;

[0052] Centrifuge the graphene-containing ...

Embodiment 2

[0058] First, at room temperature, the upper surface of the waste cathode graphite electrode produced by the molten salt electrolysis of lithium with LiCl-KCl as the raw material is mechanically peeled off 10cm thick intercalated graphite blocks and crushed into 60μm graphite powder by ball milling equipment; Placed in a liquid phase purification stripping solution containing aluminum nitrate, using nitric acid to control the pH to 1.5, the mass ratio of graphite powder to liquid phase purification stripping solution is 1:10, and the weight ratio of aluminum nitrate to graphite powder is 1: 3.5. Stir and process for 1 hour at a temperature of 90℃, stand still for layering, and separate to obtain a turbid liquid containing graphene in the upper layer for use, and impurities such as coarse graphite particles in the lower layer as coarse graphite and recovery of sodium, aluminum, and fluorine. Raw materials;

[0059] Centrifuge the graphene-containing turbid liquid by centrifugation...

Embodiment 3

[0064] First of all, at room temperature, the NdF 3 -LiF-Nd 2 O 3 The graphite electrode surface of the waste cathode produced by the molten salt electrolysis as the raw material is mechanically peeled off a 1cm thick intercalated graphite block, and is pulverized into 30μm graphite powder with a ball mill; the graphite powder is placed in a liquid phase purification layer containing aluminum chloride In the liquid, hydrochloric acid is used to control the pH value to 1.0, the mass ratio of graphite powder to liquid phase purification stripping liquid is 1:80, the weight ratio of aluminum chloride to graphite powder is 1:3, and the temperature is 60℃. 40min, stand still for layering, and separate to obtain a turbid liquid containing graphene in the upper layer and coarse graphite particles in the lower layer as raw materials for the recovery of coarse graphite and sodium, aluminum, and fluorine;

[0065] Centrifuge the graphene-containing turbid liquid by centrifugation at a low s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com