Process method for preparing high-performance carbon black masterbatch

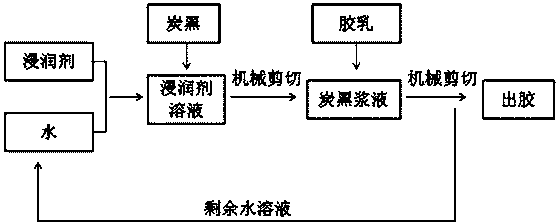

A process method and high-performance technology, applied in the field of preparation of carbon black masterbatch, can solve the problems of large dispersed particle size of carbon black, complex equipment, high energy consumption, improve solubility and dispersibility, simplify process, reduce processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Taking the dry glue quality in the natural latex as 100 parts, 50phr carbon black powder (N234) is added in the aqueous solution containing 10phr ethanol, and the mass percentage composition is the carbon black slurry of 2.5%, stirs 20min, and the natural latex is diluted to 40 % (mass percentage content, the following percentages are mass percentage content without special instructions) and then added to the carbon black slurry, stirred at a speed of 40m / min for 10min, adjusted the speed to 300m / min and stirred for 40min, and flocculated The masterbatch is taken out and dried. The above masterbatch contains 100phr of rubber, ZnO5phr, 2phr of stearic acid, 1010NA1phr of anti-aging agent, 1.2phr of accelerator CZ, and 2phr of sulfur. The rubber is mixed, and the vulcanization curve and rubber processing performance are measured after parking for 8 hours. After vulcanization at 143 ° C, the mechanical properties are measured.

Embodiment 2

[0026] Taking dry glue quality in natural latex as 100 parts, 50phr carbon black powder (N234) is added in the aqueous solution containing 50phr ethanol, the carbon black slurry that system mass percentage composition is 5%, stirs 20min, and natural latex (wherein dry 100 parts of glue) was diluted to 30% and added to the carbon black slurry, stirred at a speed of 20 m / min for 20 min, adjusted the speed of 200 m / min and stirred for 50 min, and the flocculated rubber was taken out, and the rest of the steps were as in Example 1.

Embodiment 3

[0028] Taking the dry glue quality in the natural latex as 100 parts, 50phr carbon black powder (N234) is added in the aqueous solution containing 150phr ethanol, the carbon black slurry that the system mass percentage composition is 7%, stirs 20min, and natural latex (wherein The dry glue is 100 parts) diluted to 25% and then added to the carbon black slurry, stirred at a speed of 10 m / min for 30 min, adjusted at a speed of 300 m / min and stirred for 30 min, and the flocculated rubber was taken out, and the rest of the steps were as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com