Self-emulsifying non-ionic water-based polyamideimide and preparation method thereof, carbon fiber sizing agent and preparation method and application thereof

A polyamide-imide, non-ionic technology, applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of difficult industrialization and unsuitable carbon fiber production line, etc., to reduce hygroscopicity, improve anti-humid heat aging performance, and improve dissolution. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

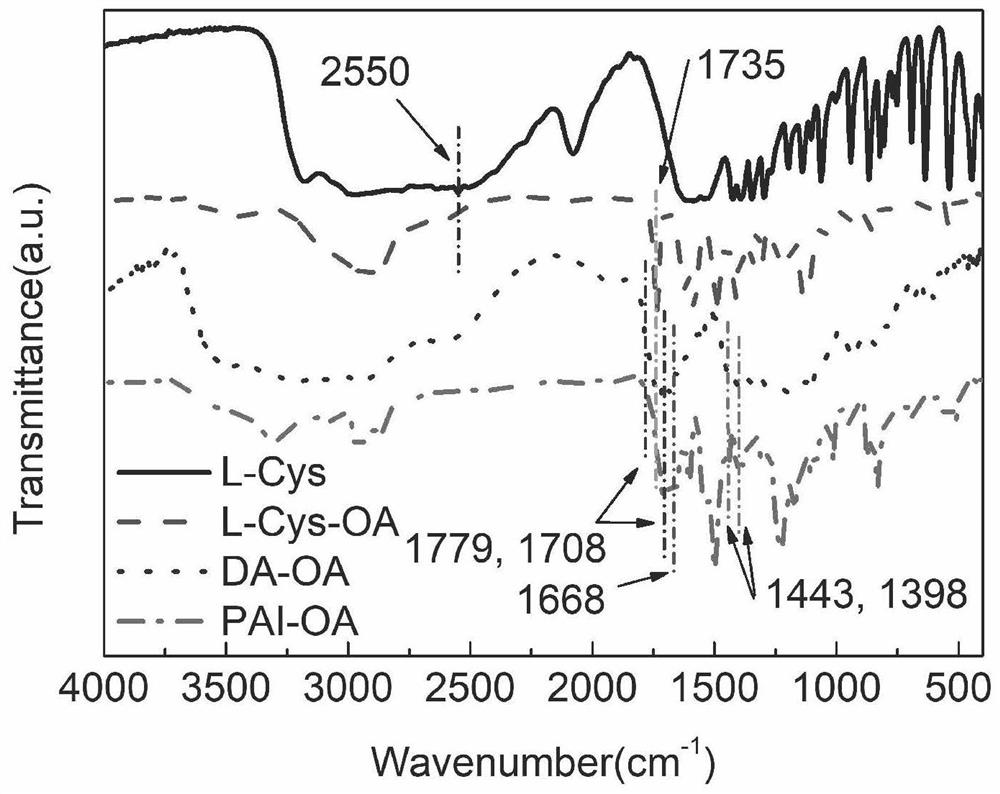

[0046] The present invention provides a self-emulsifying nonionic water-based polyamideimide, the structural formula of which is shown in formula I.

[0047]

[0048] In Formula 1, R is H or a methyl group, and X is a natural number between 1 and 9.

specific Embodiment approach 2

[0049] The present invention provides the preparation method of the self-emulsifying non-ionic water-based polyamideimide described in the specific embodiment, comprising the following steps:

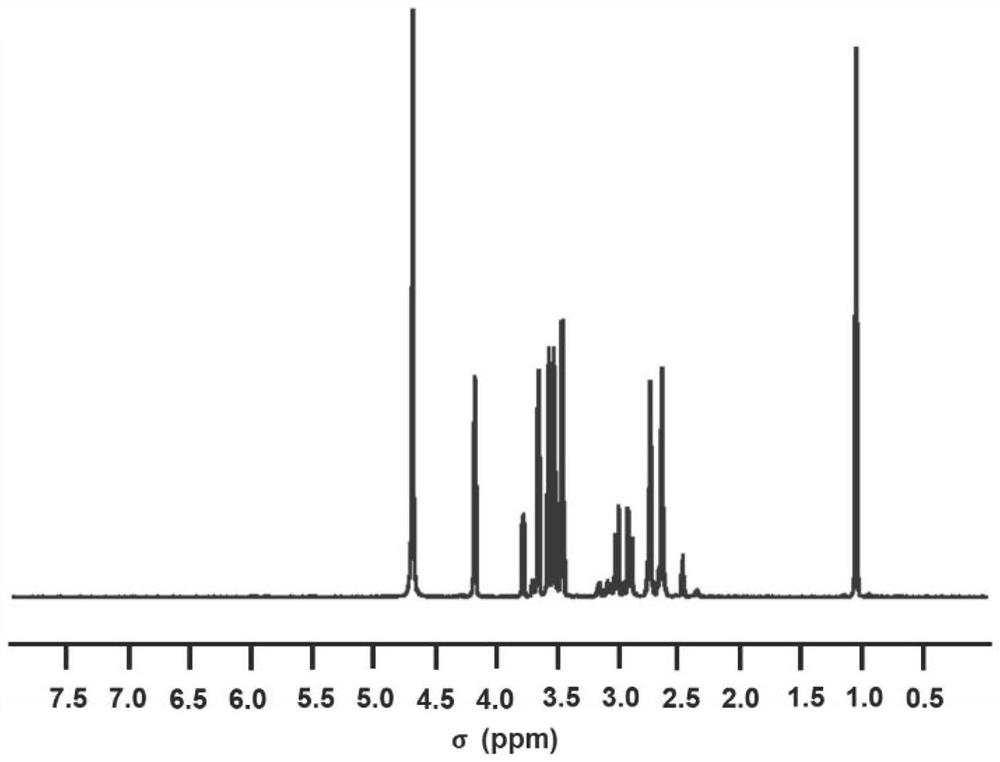

[0050] Step 1, L-cysteine reacts with an acrylate compound containing multiple ethoxy groups in water under alkali catalysis conditions to obtain a cysteine derivative, as shown in formula II, named L-Cys-OA ;

[0051]

[0052] In formula 2, R is H or methyl, and x is a natural number from 1 to 9;

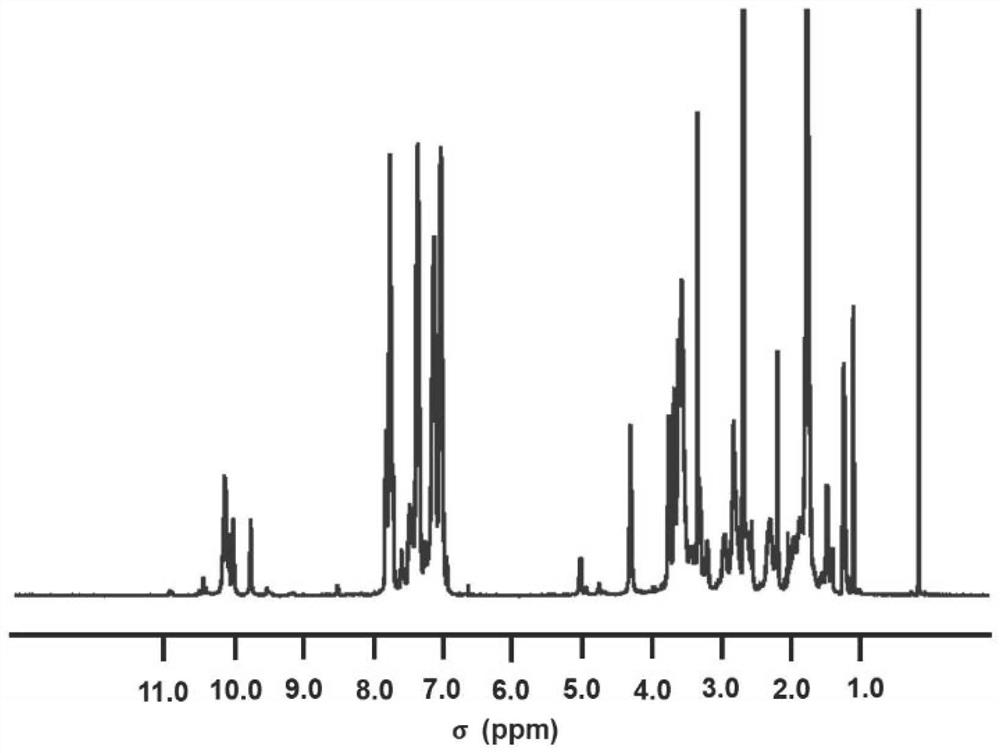

[0053] Step 2. The cysteine derivative shown in formula II is reacted with 1,2,4-cyclohexanetricarboxylic acid anhydride in glacial acetic acid to obtain a water-soluble imide acid-containing monomer, as shown in formula III, named for DA-OA.

[0054]

[0055] In formula III, R is H or methyl, and x is a natural number from 1 to 9;

[0056] Step 3. The water-soluble imide acid-containing monomer represented by formula III and 2,2-bis[4-(4-aminophenoxy)phenyl]propane are in the...

specific Embodiment approach 3

[0060] A preparation method of carbon fiber sizing agent, comprising the following steps:

[0061] The polymer PAI-OA synthesized by the specific embodiment 2 is dissolved in a small amount of organic solvent to obtain a polymer solution of a certain concentration, and this solution is directly added dropwise to a large amount of water under stirring to prepare an aqueous dispersion of a certain concentration. That is, carbon fiber sizing agent.

[0062] Further, the organic solvent is one of N,N-dimethylformamide, N,N-dimethylacetamide, N-methylpyrrolidone, and dimethyl sulfoxide; the polymer solution concentration is 10 ∼15% (w / v), specifically 15% (w / v), and the concentration of the carbon fiber sizing agent is 0.1-1 wt%, specifically 0.5 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com