High-energy barrier dysprosium single-ion magnet as well as preparation method and application thereof

A single-ion, magnet technology, applied in organic chemistry methods, chemical instruments and methods, inductance/transformer/magnet manufacturing and other directions, can solve the problems of low yield, easy decomposition or weathering, instability, etc., and achieves safe and simple process. Good reproducibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

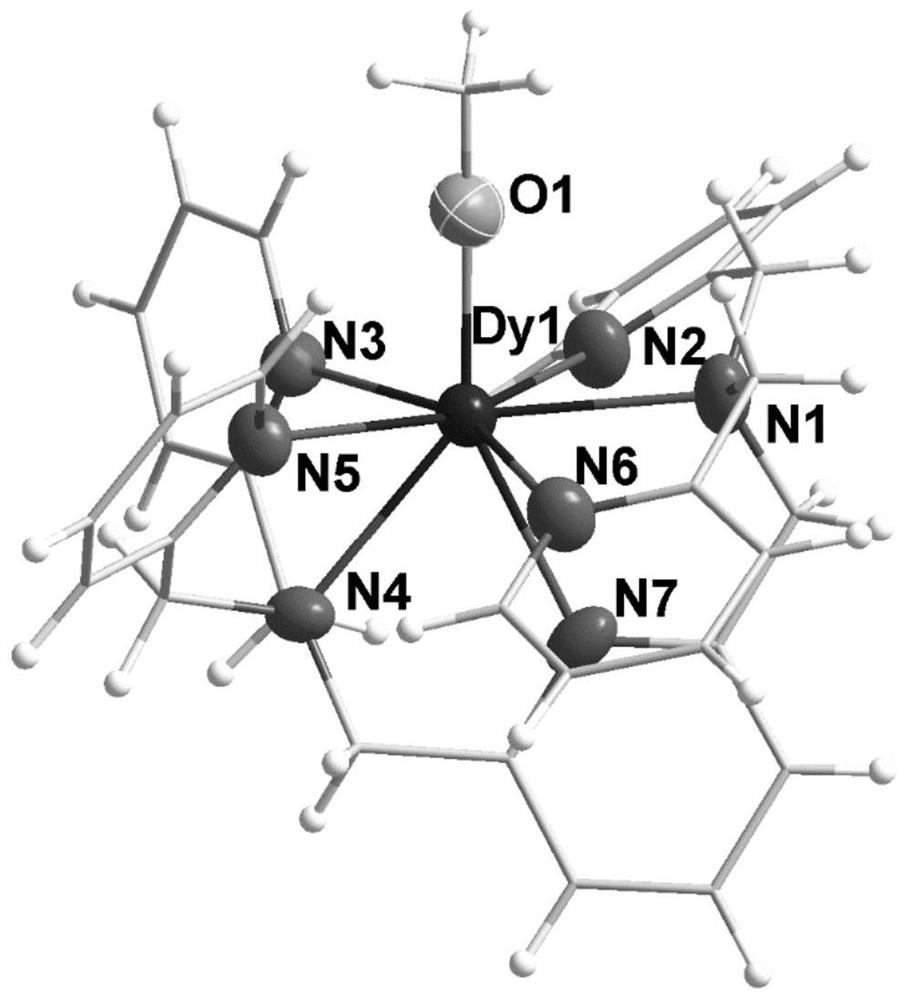

[0024] The preparation method of high energy barrier dysprosium single ion magnet, comprising: 2,6-bis(bis(2-pyridylmethyl)amino)picoline (BPA-TPA) (1mmol) and DyCl 3 ·6H 2 O (1 mmol) was dissolved in 15 mL of methanol, heated to reflux for 2 h, and a yellow clear solution was obtained. Then sodium trimethylsiliconate (2 mmol) was added, and reflux was continued for 2 h. A very small amount of yellow precipitate appeared, cooled to room temperature, and a small amount of insoluble matter was removed by filtration. , to which NaBPh was added 4 (4mmol), after stirring for 30min, a large amount of pale yellow precipitate was produced, filtered, and the precipitate was dissolved in 5mL of dichloromethane, and then 15mL of n-hexane was slowly added to it, left standstill, and two-phase diffusion was carried out for 2 days to obtain the dysprosium monoion magnet.

[0025] The yield of dysprosium single-molecule magnets prepared in this example was 66.4%.

Embodiment 2

[0027] The preparation method of high energy barrier dysprosium single ion magnet, comprising: 2,6-bis(bis(2-pyridylmethyl)amino)picoline (BPA-TPA) (1.5mmol) and DyCl 3 ·6H 2 O (1 mmol) was dissolved in 20 mL of methanol, heated to reflux for 2 h, and a yellow clear solution was obtained. Then sodium trimethylsiliconate (2.5 mmol) was added, and reflux was continued for 2 h. A very small amount of yellow precipitate appeared, cooled to room temperature, and a small amount of insoluble was removed by filtration. , to which NaBPh was added 4 (4.5mmol), after stirring for 30min, a large amount of pale yellow precipitates were produced, the precipitates were filtered out, dissolved in 8mL of dichloromethane, transferred to a test tube, 20mL of n-hexane was slowly added to it, and allowed to stand for two-phase diffusion for 3 days. That is, the dysprosium single ion magnet is obtained.

[0028] The yield of dysprosium single-molecule magnet prepared in this example was 69.2%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com