Anti-impact special-shaped flexible material cutting device

A technology of flexible materials and cutting devices, applied in vibration suppression adjustment, metal processing, spring/shock absorber, etc., can solve the problems of unstable cutting, low cutting efficiency, low cutting precision, etc., to ensure relative stability, automatic Adapt to the shock load and ensure the effect of shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The features and performance of the present invention will be described in further detail below in conjunction with the embodiments.

[0034] The frame 1 is a steel structure welded frame, and the whole is rectangular.

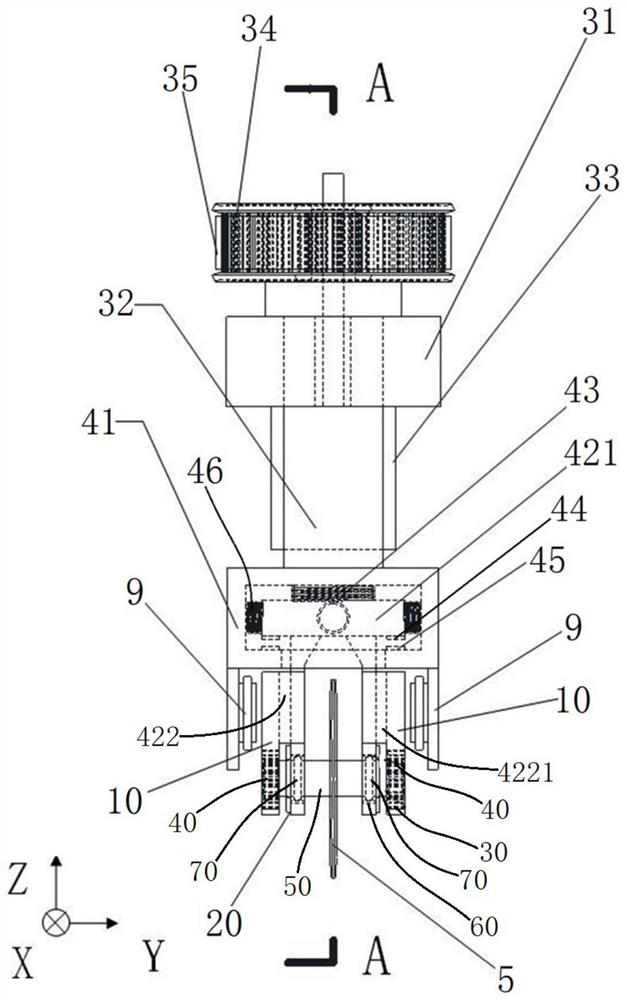

[0036] The rotary knife mechanism 3 is suspended on the output slider 231, including a bracket 31 and a connecting shaft rotatably assembled on the bracket 31

[0037] The shock absorbing device 4 includes a shock absorbing box 41 fixed on the lower end of the connecting shaft 32, and the shock absorbing box 41 has a rectangular shock absorbing cavity.

[0038] There are two driving boards 10, which are respectively attached to the outside of the two side boards 4221. The two driving boards 10 are respectively provided with

[0040] The driven synchronous pulley 36 is fixedly connected with the connecting shaft 32, and is coaxially connected with the through hole at the far end of the bracket 31. connecting shaft

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com