Poly putty specially used for multiple unit train as well as preparation method and application thereof

A technology for atomic ash and EMUs, applied in the direction of filling slurry, etc., can solve the problems of increasing train operation and maintenance costs, increasing surface cracking and falling off, hidden dangers, etc., achieving stable and controllable curing reaction, shortening of ash adjustment time, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

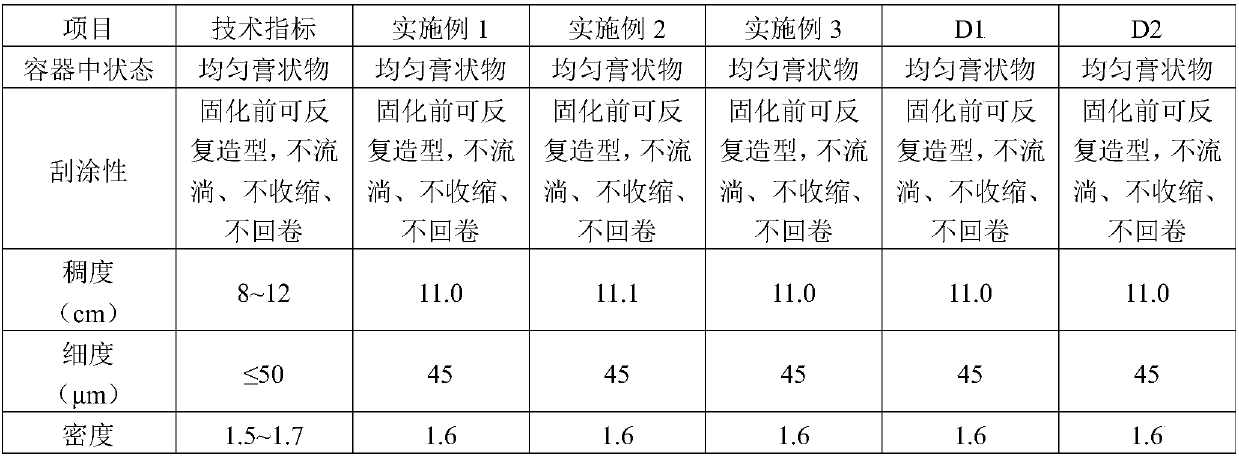

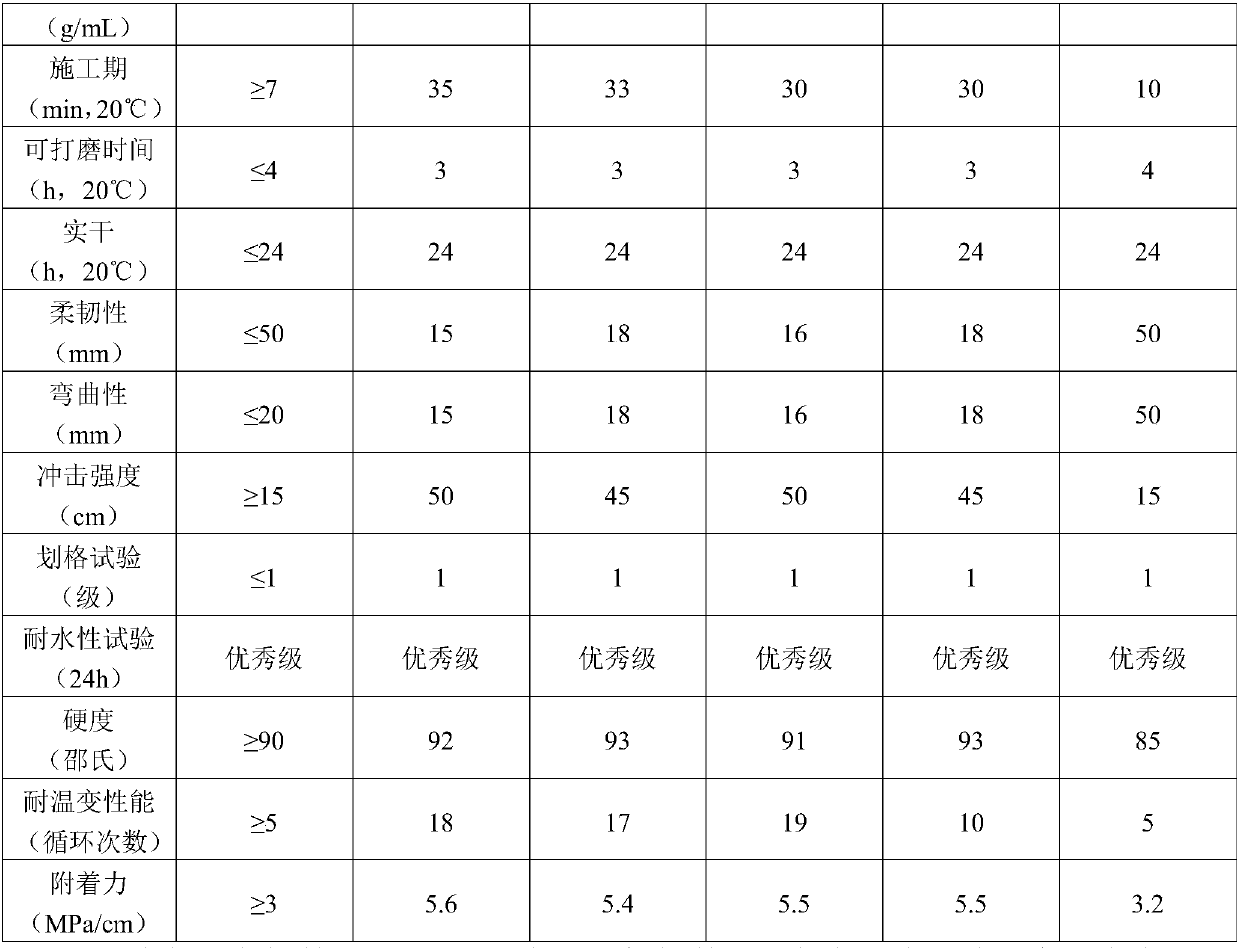

Examples

preparation example Construction

[0035] The preparation method of the most preferred composite auxiliary agent is: in parts by weight, 18 parts of TBC, 9 parts of 1,4-naphthoquinone, 37 parts of antioxidant 264, 12 parts of copper naphthenate, 24 parts Add one part of methyl ethyl ketone oxime into a mixing tank with stirring, start the stirring at a speed of 60-70 rpm, and stir at the current ambient temperature for 0.5-1 hour to form a uniform liquid substance.

[0036] The curing agent is cyclohexanone peroxide or methyl ethyl ketone peroxide.

[0037] The preparation step of described main ash comprises:

[0038] A. Preparation of compound additives

[0039] Weigh TBC, 1,4-naphthoquinone, antioxidant 264, copper naphthenate and methyl ethyl ketone oxime in proportion, add them to a mixing kettle with stirring, start stirring at 60-70 rpm, and stir at room temperature 0.5 to 1 hour to make it form a uniform liquid substance, that is, a compound additive;

[0040] B. Preparation of main ash

[0041] At ...

Embodiment 1

[0064]A kind of putty specially used for motor trains, including main ash and curing agent. The curing agent is cyclohexanone peroxide; the main ash includes: 4000g of unsaturated polyester resin, 70g of cobalt isooctanoate with a weight fraction of 8%, 300g of styrene, 40g of composite additives, and 600g of fumed silica , Titanium dioxide 800g, 325 mesh talc powder 2800g, 600 mesh talcum powder 1300g. Among them, the composite additive is composed of TBC, 1,4-naphthoquinone, antioxidant 264, copper naphthenate, and methyl ethyl ketone oxime.

[0065] The preparation process of described unsaturated polyester resin is:

[0066] Weigh 650g of diethylene glycol, 400g of ethylene glycol, 350g of neopentyl glycol, 700g of tetrahydrophthalic anhydride, and 200g of adipic acid into the reaction kettle, raise the temperature to 200°C, and keep it warm for 3.5 hours. The acid value is 60mgKOH / g Afterwards, cool down to 180°C, add 900g of maleic anhydride, raise the temperature to 2...

Embodiment 2

[0074] A kind of putty specially used for motor trains, including main ash and curing agent. The curing agent is cyclohexanone peroxide; the main ash includes: 4000g of unsaturated polyester resin, 70g of cobalt isooctanoate with a weight fraction of 8%, 500g of styrene, 50g of composite additives, and 700g of fumed silica , Titanium dioxide 800g, 325 mesh talc powder 2900g, 600 mesh talcum powder 1200g. Among them, the composite additive is composed of TBC, 1,4-naphthoquinone, antioxidant 264, copper naphthenate, and methyl ethyl ketone oxime.

[0075] The preparation process of described unsaturated polyester resin is:

[0076] Weigh 650g of diethylene glycol, 400g of ethylene glycol, 350g of neopentyl glycol, 700g of tetrahydrophthalic anhydride, and 200g of adipic acid into the reaction kettle, raise the temperature to 200°C, and keep it warm for 3.5 hours. The acid value is 58mgKOH / g Afterwards, cool down to 180°C, add 900g of maleic anhydride, raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com