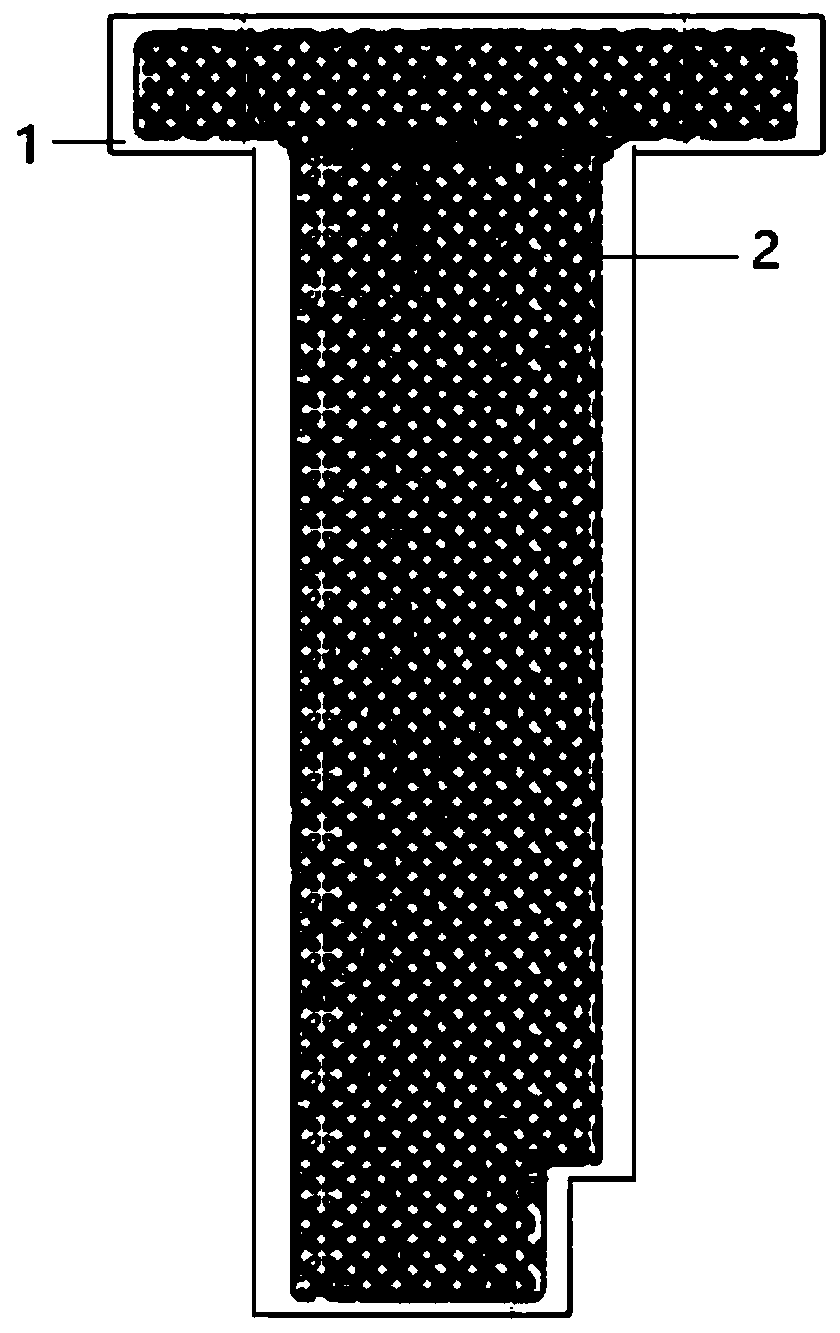

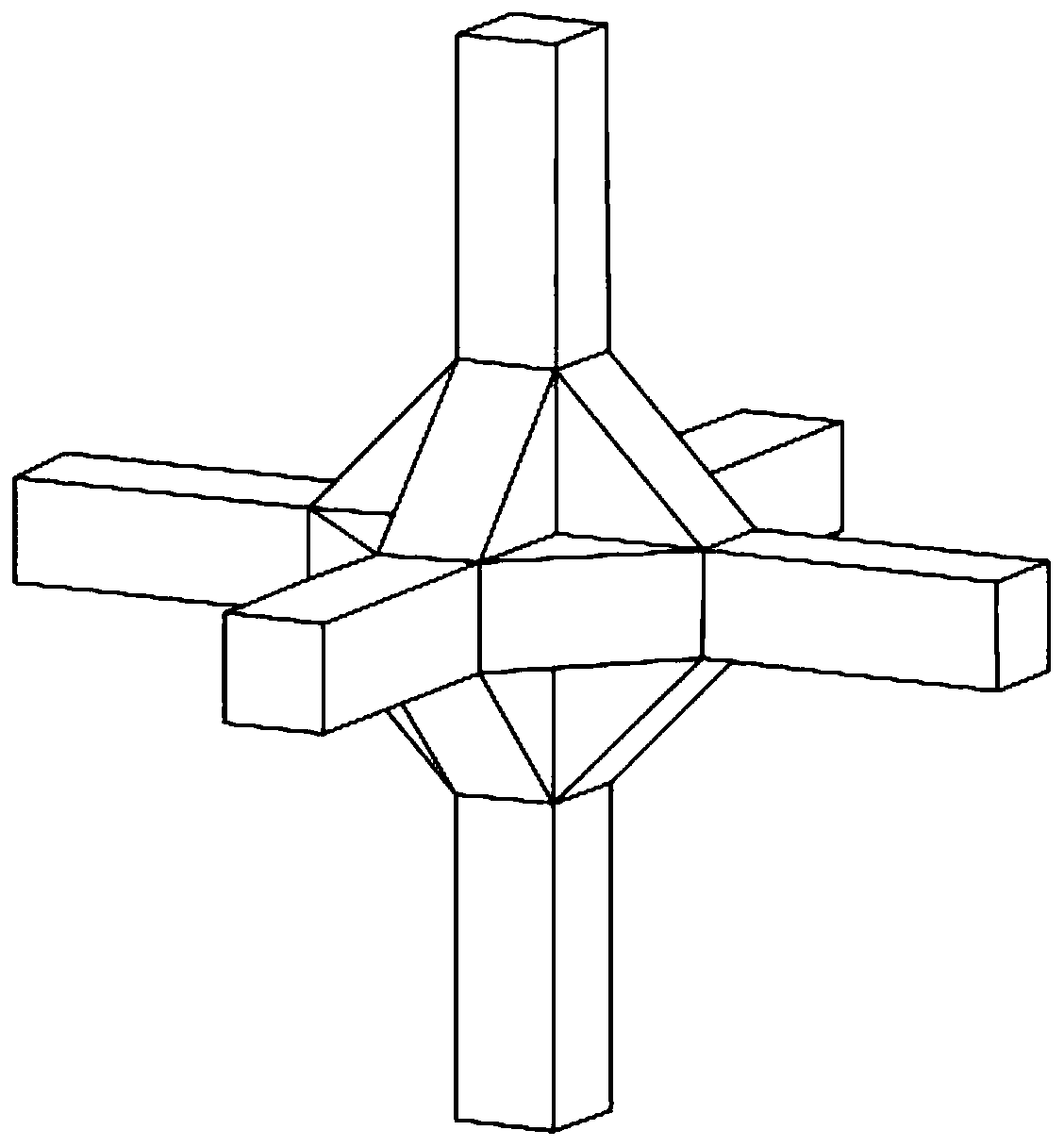

Hollow blade easy-to-remove aluminum oxide ceramic core and preparation method thereof

A technology of alumina ceramics and hollow blades, which is applied in cores, casting molding equipment, casting molds, etc., can solve the problems of high cost, unsuitable for mass production, and complicated manufacturing process of core rods, and achieves increased contact area. , The effect of shortening the core removal time and saving ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The specific implementation steps of the ceramic core made of alumina ceramic paste using 3D printing molding technology are as follows:

[0049] 1) Take 40g of alumina, 200ml of absolute ethanol and 0.4g of organosilicate and mix and stir for 10h.

[0050] 2) filtering and drying to prepare surface-functionalized graded alumina ceramic powder.

[0051] 3) Take 10g of silicon dioxide, 100ml of absolute ethanol and 0.2g of organosilicate and mix and stir for 10h.

[0052] 4) Filtrating and drying to prepare surface-functionalized graded silica ceramic powder.

[0053] 5) Mix 100ml of acrylic resin with an average molecular weight of 2500, 120ml of butyl acrylate, 20ml of methyl benzoylformate and 10ml of polydimethylsiloxane to prepare a photocurable resin premix.

[0054] 6) Mixing and stirring the graded alumina ceramic powder and the photocurable resin premix to obtain a photocurable ceramic slurry.

[0055] 7) Create a ceramic core model entity in the 3D modeling ...

Embodiment 2

[0072] The specific implementation steps of the ceramic core made of alumina ceramic paste using 3D printing molding technology are as follows:

[0073] 1) Take 35g of alumina, 200ml of absolute ethanol and 0.3g of organosilicate and mix and stir for 10h.

[0074] 2) filtering and drying to prepare surface-functionalized graded alumina ceramic powder.

[0075] 3) Take 8g of silicon dioxide, 120ml of absolute ethanol and 0.2g of organosilicate and mix and stir for 10h.

[0076] 4) Filtrating and drying to prepare surface-functionalized graded silica ceramic powder.

[0077] 5) Mix 100ml of acrylic resin with an average molecular weight of 2000, 120ml of butyl acrylate, 20ml of methyl benzoylformate and 10ml of polydimethylsiloxane to prepare a photocurable resin premix.

[0078] 6) Mixing and stirring the graded alumina ceramic powder and the photocurable resin premix to obtain a photocurable ceramic slurry.

[0079] 7) Create a ceramic core model entity in the 3D modeling s...

Embodiment 3

[0094] The specific implementation steps of the ceramic core made of alumina ceramic paste using 3D printing molding technology are as follows:

[0095] 1) Take 45g of alumina, 220ml of absolute ethanol and 0.3g of organosilicate and mix and stir for 10h.

[0096] 2) filtering and drying to prepare surface-functionalized graded alumina ceramic powder.

[0097] 3) Take 12g of silicon dioxide, 120ml of absolute ethanol and 0.3g of organosilicate and mix and stir for 10h.

[0098] 4) Filtrating and drying to prepare surface-functionalized graded silica ceramic powder.

[0099] 5) Mix 110ml of acrylic resin with an average molecular weight of 2500, 135ml of butyl acrylate, 25ml of methyl benzoylformate and 12ml of polydimethylsiloxane to prepare a photocurable resin premix.

[0100] 6) Mixing and stirring the graded alumina ceramic powder and the photocurable resin premix to obtain a photocurable ceramic slurry.

[0101] 7) Create a ceramic core model entity in the 3D modeling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com