High-light-transmittance organic glass sample preparation equipment and method thereof

A plexiglass and sample preparation technology, applied in the preparation, sampling, instruments and other directions of test samples, can solve the problems of poor cooling effect, large water consumption, increase production process and other problems, and achieve the effect of maintaining the cooling effect and speeding up the molding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

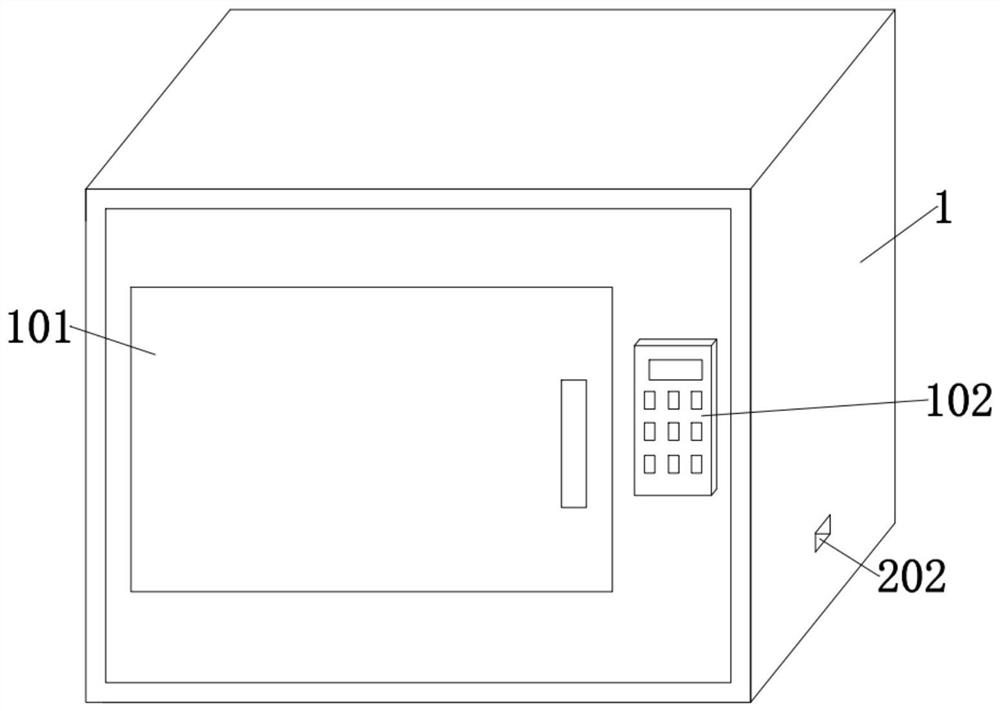

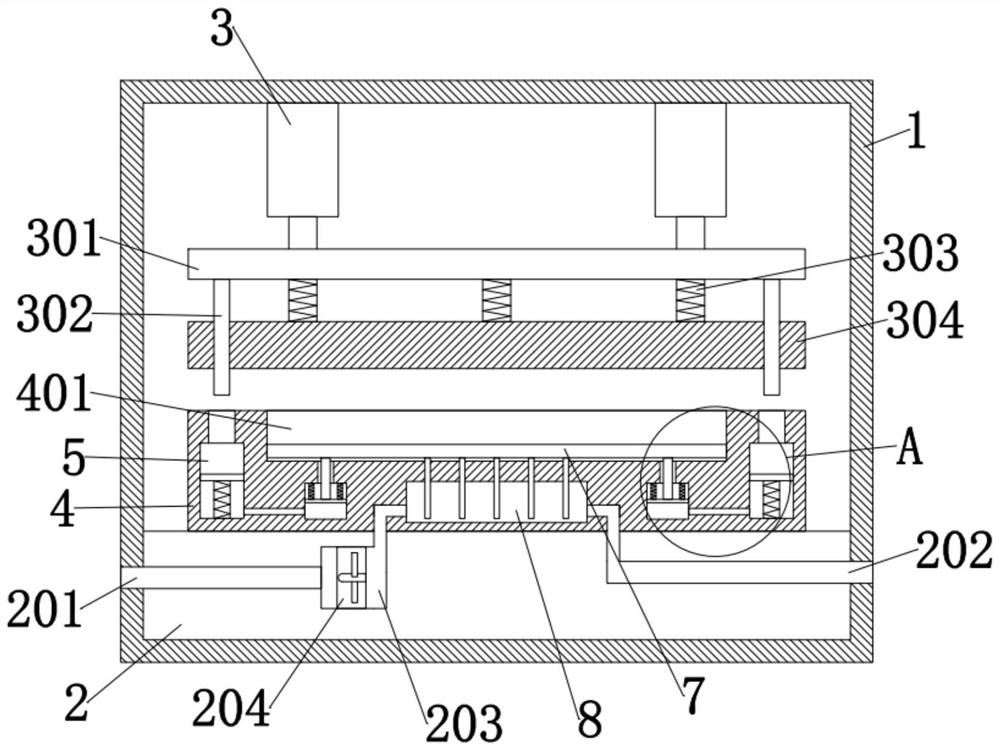

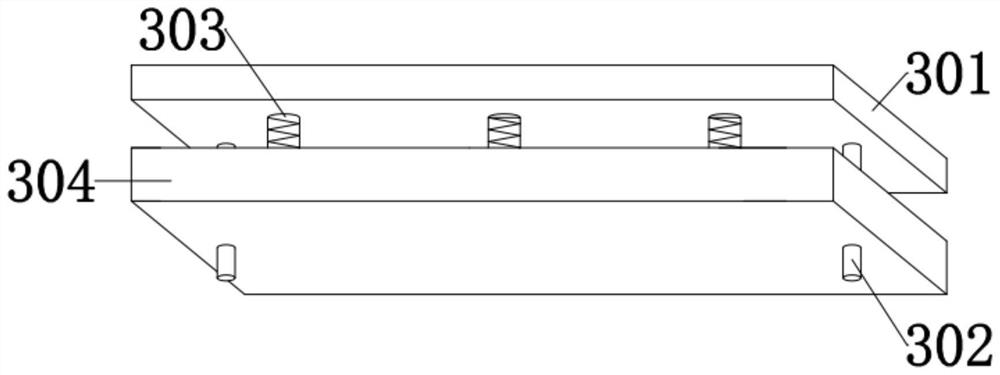

[0054] see Figure 1-7 Among them, a high-transparency plexiglass sample preparation device provided in this embodiment includes: a box body 1, a workbench 2 fixedly installed inside the box body 1 for installing the forming block 4, and fixedly installed on the workbench 2 The top is a forming block 4 for cooling and forming plexiglass, an extrusion component arranged inside the forming block 4 for compressing the material solution, and a cooling component disposed inside the forming block 4 and the table 2 to cool the material.

[0055] Further, the cooling assembly includes: a heat dissipation cavity 8 opened in the forming block 4, a ventilation duct 203 opened in the worktable 2, an exhaust fan 204 fixedly installed in the ventilation duct 203, and the heat dissipation cavity 8 is connected with the ventilation duct 203. , the front of the box body 1 is connected with a box door 101 through hinges, and the front of the box body 1 is fixedly installed with a control panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com