Skin-core type composite fiber bundle as well as preparation method and application thereof

A composite fiber, skin-core technology, used in fiber processing, fiber chemical characteristics, stretch spinning, etc., can solve the problems of easy closure of the inner cavity of the fiber, interpenetration, and loss of the liquid conduction function of the fiber. Excellent water conductivity, simple preparation process, high strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

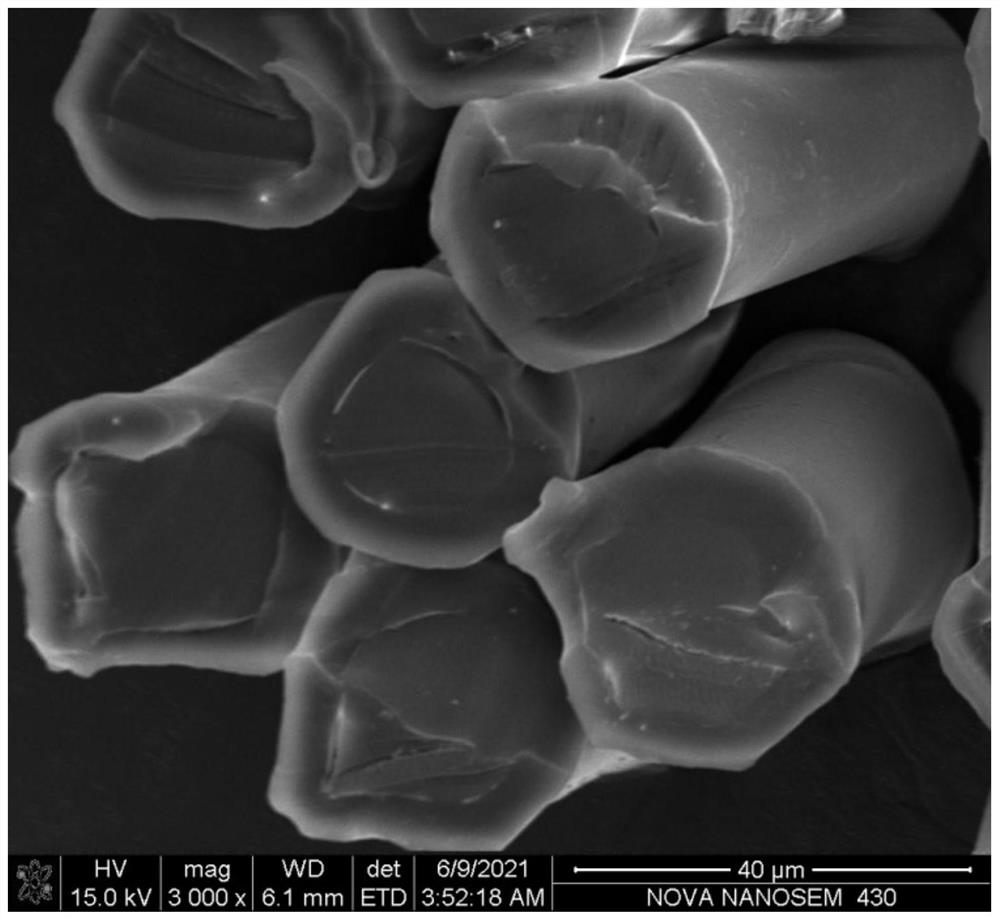

Image

Examples

Embodiment 1

[0041] A kind of sheath-core type composite fiber bundle, its preparation method comprises the following steps:

[0042] 1) With the polyethylene of 65 mass parts, the ethylene-propylene copolymer of 30 mass parts and the maleic anhydride grafted polyethylene of 5 mass parts as cortex material, carry out drying first, then add the first screw extruder, pass through the second A metering pump carries out melt distribution and enters the composite spinning pack, and 500 mass parts of polyethylene terephthalate and 400 mass parts of polyethylene terephthalate-1,4-cyclohexane Dimethyl ester copolymer is used as the core layer material, first dried, then added to the second screw extruder, and the melt is distributed through the second metering pump into the composite spinning assembly for composite spinning to obtain primary composite fibers;

[0043] 2) Stretch the nascent composite fiber by 1 time at 160°C, and then perform heat setting treatment at 140°C for 60s to obtain a she...

Embodiment 2

[0055] A kind of sheath-core type composite fiber bundle, its preparation method comprises the following steps:

[0056] 1) 97 parts by mass of polypropylene, 2 parts by mass of ethylene-propylene-non-conjugated diene copolymer and 1 part by mass of maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer As the cortex material, it is dried first, then added to the first screw extruder, and the melt is distributed into the composite spinning assembly through the first metering pump, and 900 parts by mass of polyethylene terephthalate-polyethylene Glycol block copolymer is used as the core layer material, first dried, then added to the second screw extruder, and the melt is distributed through the second metering pump into the composite spinning assembly for composite spinning to obtain primary composite fibers;

[0057] 2) Stretch the nascent composite fiber by 7 times at 195°C, and then perform heat setting treatment at 180°C for 150s to obtain a sheath-cor...

Embodiment 3

[0067] A kind of sheath-core type composite fiber bundle, its preparation method comprises the following steps:

[0068] 1) Use 90 parts by mass of polypropylene, 8 parts by mass of ethylene-butene copolymer and 2 parts by mass of glycidyl methacrylate grafted polypropylene as the skin layer material, dry it first, and then add the first screw extrusion Machine, through the first metering pump, the melt is distributed into the composite spinning assembly, and 538 parts by mass of polybutylene terephthalate and 28 parts by mass of polyethylene are used as core material, first dried, and then added to the second Two-screw extruder, through the second metering pump, the melt is distributed into the composite spinning assembly, and composite spinning is performed to obtain primary composite fibers;

[0069] 2) Stretch the nascent composite fiber 3 times at 180°C, and then perform heat setting treatment at 160°C for 300s to obtain a sheath-core composite fiber bundle.

[0070] Not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com