High-elongation low-modulus polyurethane elastic fiber and preparation method thereof

A polyurethane elastic, low-modulus technology, applied in the direction of fiber chemical characteristics, textile/flexible product manufacturing, rayon manufacturing, etc., can solve problems such as reducing production costs, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

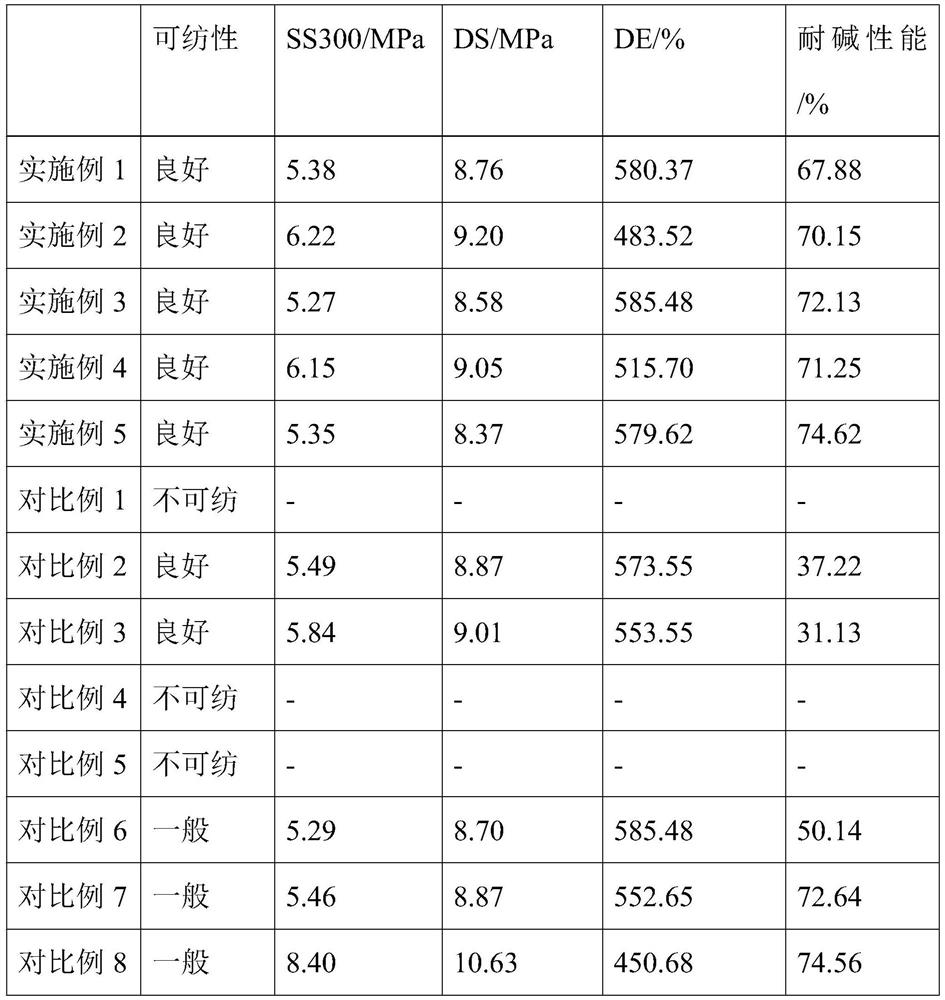

Examples

Embodiment 1

[0048] In this example, the high elongation low modulus polyurethane elastic fiber is prepared by the following steps:

[0049] 1. Polycondensation of 50.00kg polyester diol (3-methyl-1,3-butanediol, 1,4-butanediol, adipic acid in a molar ratio of 0.27:0.28:0.45, molecular weight 1800), 50.00 kg polytetramethylene ether glycol (molecular weight 1800) is mixed with 0.80kg 5A molecular sieve to form a glycol mixture;

[0050] 2. 23.46kg of 4,4'-diphenylmethane diisocyanate and 100.80kg of diol mixture were simultaneously sent to the first reactor, the reaction time was 2.2h, and the reaction temperature was 70°C to obtain an isocyanate-terminated prepolymer, which was In the dissolving machine, 195.53 kg of N,N-dimethylacetamide was used as a solvent to fully dissolve the isocyanate-terminated prepolymer to obtain an isocyanate-terminated prepolymer N,N-dimethylacetamide solution;

[0051] 3. Mix 319.79kg isocyanate-terminated prepolymer N,N-dimethylacetamide solution and 50.40...

Embodiment 2

[0056] In this example, the high elongation low modulus polyurethane elastic fiber is prepared by the following steps:

[0057] 1. Polycondensate 40.00kg of polyester diol (3-methyl-1,3-butanediol, 1,4-butanediol, adipic acid in a molar ratio of 0.3:0.25:0.45, molecular weight 1800, molecular weight of The determination adopts gel permeation chromatography (GPC, Shimadzu LC-20AD, Japan) to measure), 60.00kg polytetramethylene ether glycol (BASF Co., Ltd. trade mark is PTHF-1800 product, molecular weight 1800) is mixed with 0.80kg5A molecular sieve, form a diol mixture;

[0058] 2. 23.46kg of 4,4'-diphenylmethane diisocyanate and 100.80kg of diol mixture were sent to the first reactor at the same time, the reaction time was 2.2h, and the reaction temperature was 70°C to obtain an isocyanate-terminated prepolymer. In the dissolving machine, 195.53 kg of N,N-dimethylacetamide was used as a solvent to fully dissolve the isocyanate-terminated prepolymer to obtain an isocyanate-ter...

Embodiment 3

[0064] In this example, the high elongation low modulus polyurethane elastic fiber is prepared by the following steps:

[0065] 1. Polycondensate 60.00kg of polyester diol (2,5-dimethyl-2,5-hexanediol, 1,4-butanediol, and adipic acid in a molar ratio of 0.27:0.27:0.45, molecular weight 1800 ), 40.00kg polytetramethylene ether glycol (molecular weight 1800) are mixed with 0.50kg ZSM-5 molecular sieve to form a glycol mixture;

[0066] 2. 23.46kg of 4,4'-diphenylmethane diisocyanate and 100.80kg of diol mixture were simultaneously sent to the first reactor, the reaction time was 2.2h, and the reaction temperature was 70°C to obtain an isocyanate-terminated prepolymer, which was In the dissolving machine, 195.53 kg of N,N-dimethylacetamide was used as a solvent to fully dissolve the isocyanate-terminated prepolymer to obtain an isocyanate-terminated prepolymer N,N-dimethylacetamide solution;

[0067] 3. Mix 319.79kg isocyanate-terminated prepolymer N,N-dimethylacetamide solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com