One-sided reed traversing driving mechanism

A traversing mechanism and reed technology are applied in the field of unilaterally driven reed traversing mechanisms to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

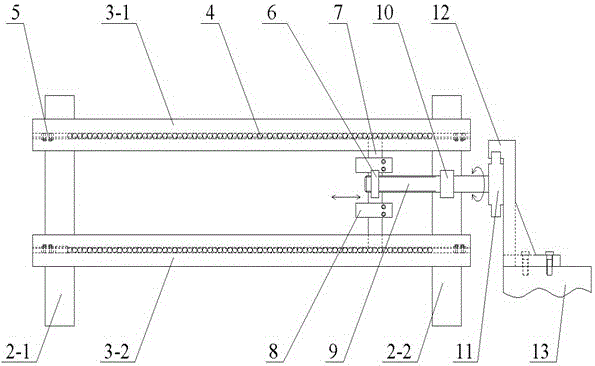

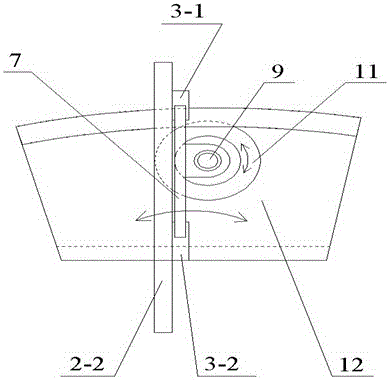

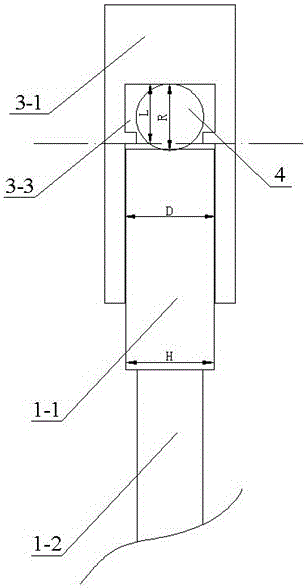

[0022] The embodiments will be further described below in conjunction with the accompanying drawings. Such as figure 1 Shown, install upper and lower reed caps 3-1, 3-2 additionally on the sley feet 2-1 and 2-2 of the shuttleless loom. The shape of the reed hat is as image 3 As shown, it is groove-shaped, and its groove width D is equal to the thickness H of the reed beam 1-1. Such as Figure 5 with figure 1 As shown, the reed 1 is loosely installed between the upper and lower reed caps 3-1 and 3-2, and the reed connector 8 is used to connect the reed and the slide block 7 as one. Two of slide block 7 stretch in the groove of reed cap, loosely dress on the right side between two reed caps, can move left and right along reed cap length direction, also drive steel reed to move sideways simultaneously.

[0023] The left and right movement of slide block 7 is realized in the following way. Such as figure 1 , a drive nut 6 is fixed on the slider 7, a bearing 10 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com