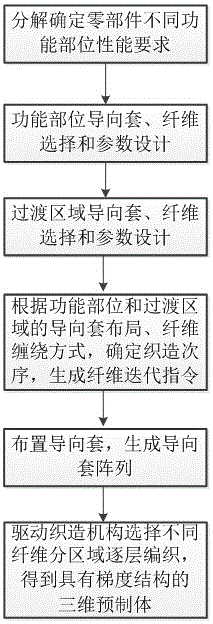

A Weaving Method of Three-dimensional Prefabricated Body with Gradient Structure

A gradient structure and prefabricated body technology, which is applied in textiles, papermaking, textiles, looms, etc., can solve the problem of not being able to weave three-dimensional prefabricated bodies, and achieve the effect of less dependence on labor and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

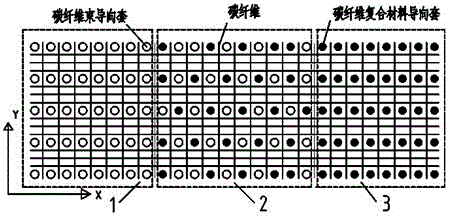

[0029] 1. Make a fiber-reinforced composite material prefabricated body with a carbon fiber cross-sectional size of 250mm×80mm×30mm. The working condition is that the main structure bears static load, and the X direction bears part of the dynamic load on the left side. Divide the prefab structure into 3 parts like figure 2 As shown, 1 is the full-fiber weaving area, 3 is the weaving area using the carbon fiber composite material guide sleeve in the Z direction, and 2 is the transition area between the full-fiber weaving area 1 and the Z-direction weaving area 3 using the carbon fiber composite material guide sleeve;

[0030] 2. According to the overall loading situation, the fibers are laid in the three directions of X, Y, and Z in the space, and the fibers in the X and Y directions running through the full fiber weaving area 1 and the Z direction using the carbon fiber composite guide sleeve in the weaving area 3 use T300 -6K carbon fiber, the fiber winding method is linear,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com