Electromagnetic shielding tarpaulin

A technology of electromagnetic shielding and tarpaulin, which is applied in fabrics, textiles, textiles, and papermaking, and can solve problems such as low strength index, low efficiency, and easy wear of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

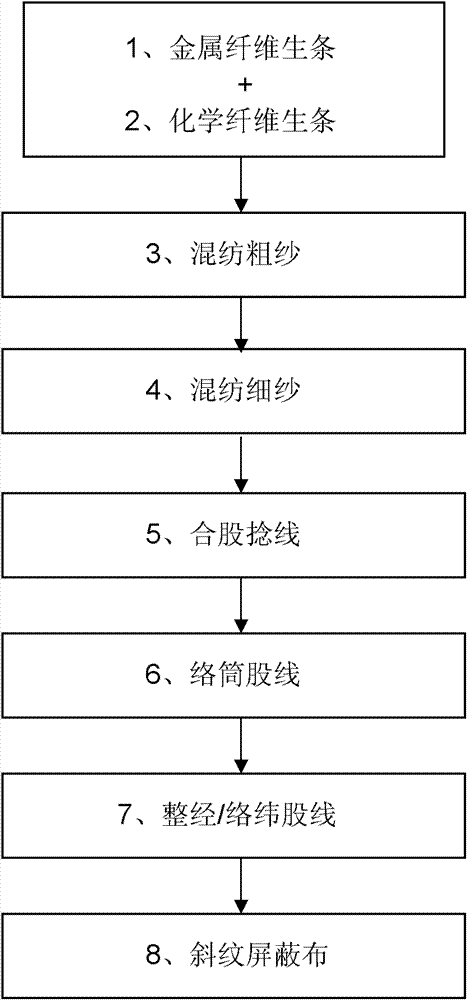

[0009] Referring to the drawings, the present invention mainly includes metal fiber 1, chemical fiber 2, blended roving 3, blended spun yarn 4, ply twisted yarn 5, winding strand 6, full diameter and weft strand 7, twill shielding cloth 8 .

[0010] During processing and weaving, stainless steel metal fiber raw sliver 1 and polyester chemical fiber raw sliver 2 are used for drawing. The number of drawing depends on the uniformity of the mixing of 1 and 2. After several times of drawing and mixing, a uniform mixture of front, back and inside is formed. Fiber roving sliver 3, roving sliver 3 is stretched and twisted to form fine yarn 4, yarn 4 is plied and twisted to form strand 5, strand 5 is wound to form bobbin 6, and bobbin 6 is wound twice Finally, the diameter and latitude are formed into diameter and weft strands 7, and the strands 7 are woven into a blended electromagnetic shielding tarpaulin 8 by adopting the 2 / 1 twill weave method.

[0011] The blended electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com