Creep-resistant high-temperature-resistant rare earth aluminum alloy and preparation method thereof

A technology of creep resistance and high temperature resistance, applied in the field of aluminum alloys, can solve problems such as mutual inhibition, and achieve the effect of refining grains, improving creep resistance, and increasing yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

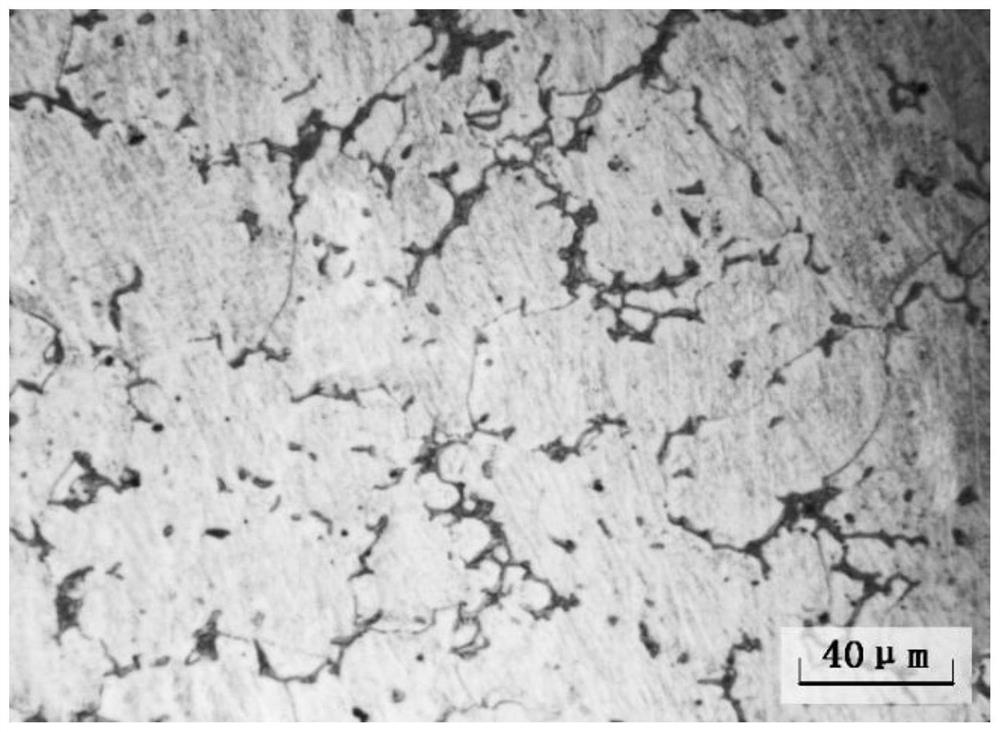

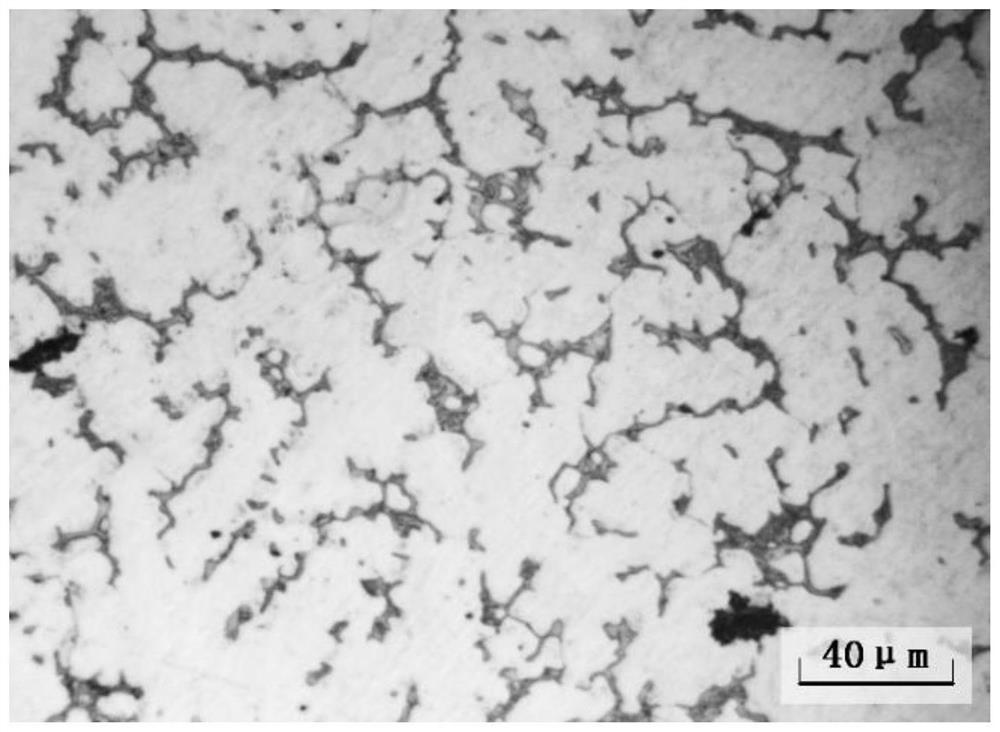

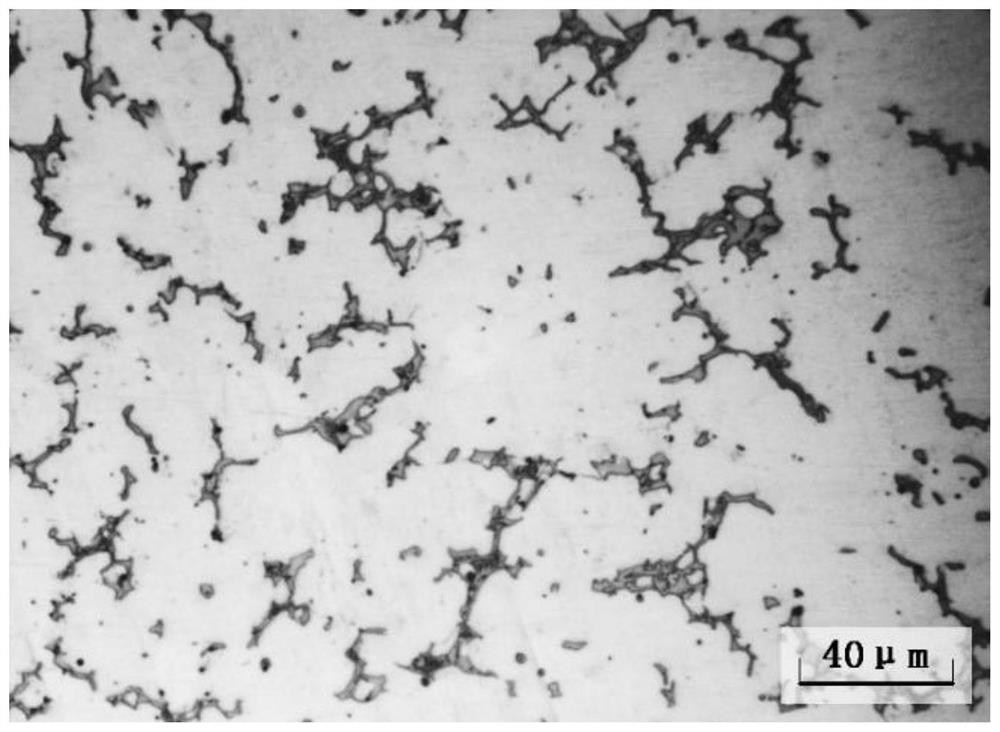

Image

Examples

Embodiment 1

[0033] Step 1: Accurately weigh aluminum, zinc, magnesium and master alloy Al- Hf, Al-Gd and Al-Zr are sent to the preheating kettle for preheating;

[0034] Step 2: put the aluminum into the melting kettle for melting, heat up to 700°C after melting, add zinc and magnesium, and add the master alloys Al-Hf, Al-Gd and Al-Zr when the melt temperature reaches 720°C;

[0035] Step 3: stir for 3 minutes to fully melt, then heat up to 790°C, keep the temperature for 25 minutes, then cool down, refine for 6 minutes, and let stand for 30 minutes;

[0036] Step 4: Cooling, removing surface scum, and casting.

Embodiment 2

[0038] Step 1: Accurately weigh aluminum, zinc, magnesium and master alloy Al- Hf, Al-Gd and Al-Zr are sent to the preheating kettle for preheating;

[0039] Step 2: put the aluminum into the melting kettle for melting, heat up to 700°C after melting, add zinc and magnesium, and add the master alloys Al-Hf, Al-Gd and Al-Zr when the melt temperature reaches 720°C;

[0040] Step 3: stir for 3 minutes to fully melt, then heat up to 790°C, keep the temperature for 25 minutes, then cool down, refine for 6 minutes, and let stand for 30 minutes;

[0041] Step 4: Cooling, removing surface scum, and casting.

Embodiment 3

[0043] Step 1: Accurately weigh aluminum, zinc, magnesium and master alloy Al- Hf, Al-Gd and Al-Zr are sent to the preheating kettle for preheating;

[0044] Step 2: put the aluminum into the melting kettle for melting, heat up to 700°C after melting, add zinc and magnesium, and add the master alloys Al-Hf, Al-Gd and Al-Zr when the melt temperature reaches 720°C;

[0045] Step 3: stir for 3 minutes to fully melt, then heat up to 790°C, keep the temperature for 25 minutes, then cool down, refine for 6 minutes, and let stand for 30 minutes;

[0046] Step 4: Cooling, removing surface scum, and casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com