Low-cost high-efficiency open circuit for arsenic in copper electrolysis and resource utilization method of low-cost high-efficiency open circuit

A low-cost, copper electrolysis technology, applied in the direction of electrolysis components, electrolysis process, process efficiency improvement, etc., can solve the problem of high content of antimony or bismuth, and achieve the effect of low cost, satisfying requirements and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

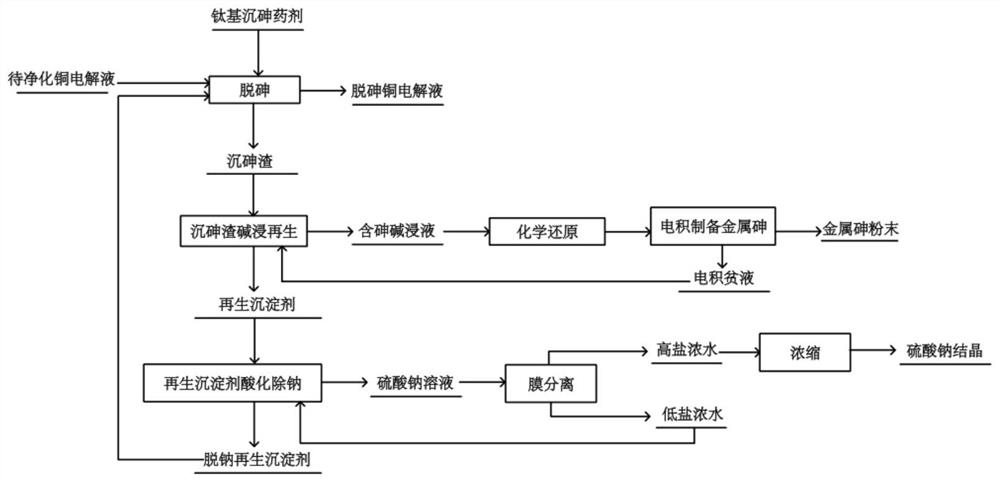

[0028] This embodiment provides a low-cost, high-efficiency open circuit for arsenic in copper electrolysis and a method for resource utilization thereof. The process is as follows figure 1 shown.

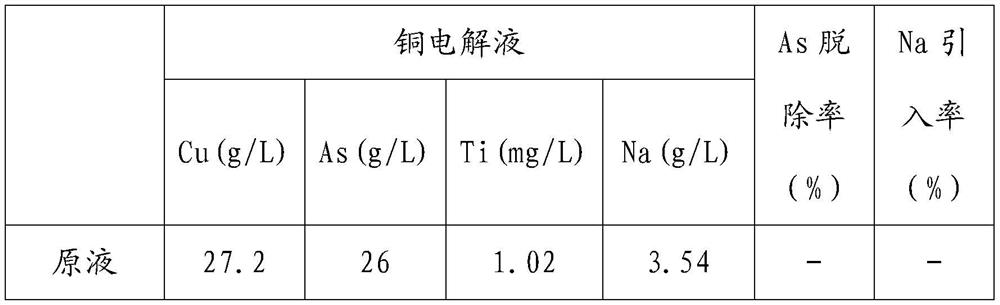

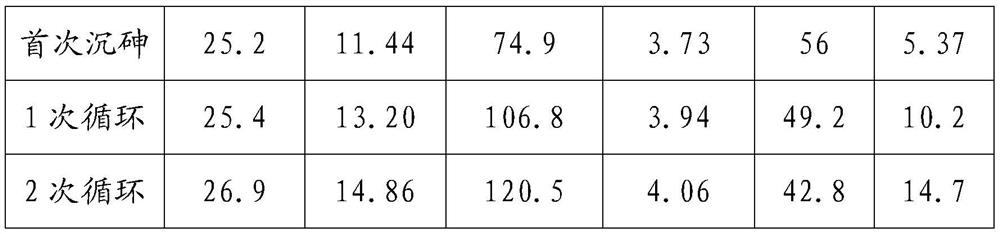

[0029] Main element content of copper electrolyte water sample: Cu 27.2g / L, As 26g / L, Ti 1.02mg / L, Na 3.54g / L, H 2 SO 4 353g / L.

[0030] (1) Preparation of precipitant

[0031] 70 g of titanyl sulfate was dissolved in 1.4 L of deionized water, and the reaction was stirred to 5 °C by an ice-water bath method. Slowly add 480g / L sodium hydroxide solution to adjust the pH to about 5. After the reaction is completed, carry out solid-liquid separation, and wash with deionized water until the conductivity is at 50us.cm -1 about, drying and grinding to obtain a titanium-containing precipitant.

[0032] (2) Arsenic removal

[0033] The addition amount of the titanium-containing precipitant is 1 times the mass of the total arsenic. Specifically, 26 g of the activated titanium-containi...

Embodiment 2

[0049] This embodiment provides a low-cost, high-efficiency open circuit for arsenic in copper electrolysis and a method for resource utilization thereof.

[0050] Main element content of copper electrolyte water sample: Cu 10.78g / L, As 23.92g / L, Ti2 SO 4 320.3g / L.

[0051] (1) Arsenic removal

[0052] The amount of titanium sulfate added is twice the mass of the total arsenic. Specifically, 191.36g of titanium sulfate is added to 4L of copper electrolyte, and the reaction is carried out at a temperature of 90 ° C for 1 hour; Arsenic residue;

[0053] (2) Alkaline leaching regeneration of arsenic-containing slag

[0054] The precipitation arsenic residue and 250g / L sodium hydroxide solution were mixed according to a liquid-solid mass ratio of 2:1, and the reaction was carried out at a temperature of 110 ° C for 1 hour; after liquid-solid separation, an arsenic-containing alkali leaching solution and a regenerated precipitant were obtained;

[0055] (3) Regenerating precipit...

Embodiment 3

[0067] This embodiment provides a low-cost, high-efficiency open circuit for arsenic in copper electrolysis and a method for resource utilization thereof.

[0068] Main element content of copper electrolyte water sample: Cu 59.69g / L, As 11.58g / L, Ti 0.42mg / L, Na3.44g / L, H 2 SO 4 186g / L.

[0069] (1) Arsenic removal

[0070] The addition amount of the titanium-containing precipitating agent is 5 times the mass of the total arsenic. Specifically, adding 57.9 g of the activated precipitating agent prepared by titanium oxysulfate to 1 L of copper electrolyte, and reacting at 60°C for 6 hours; Separation to obtain dearsenic electrolyte solution and arsenic precipitation residue;

[0071] (2) Alkaline leaching regeneration of precipitation arsenic residue

[0072] The precipitation arsenic residue and 100g / L sodium hydroxide solution are mixed according to the liquid-solid ratio of 5, and the reaction temperature is controlled to be 90°C and the reaction time is 2 hours;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com