Method for extracting DNJ in mulberry leaves through hydrothermal acid control and alcohol extraction

A mulberry leaf and hydrothermal technology, applied in organic chemistry, climate sustainability, chemical industry and other directions, can solve the problem of increasing equipment maintenance costs, hydrochloric acid environmental treatment costs, increasing production equipment purchase costs and production energy consumption, increasing production costs and increasing production costs. Environmental governance costs and other issues, to achieve the effect of realizing the utilization of mulberry leaves, improving the utilization rate of mulberry leaves, and reducing the impact of equipment and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concrete steps of a kind of hydrothermal acid-controlled alcohol extraction of DNJ in mulberry leaves are as follows:

[0020] (1) Raw material pretreatment

[0021] Using mulberry leaves (including fresh mulberry leaves, waste mulberry leaves, and leftovers from the processing of mulberry leaves) as raw materials. First wash the raw materials with water, then place them in an oven at 100 °C for 60 minutes, then grind them through a pulverizer and pass through a 60-mesh sieve. processed raw material.

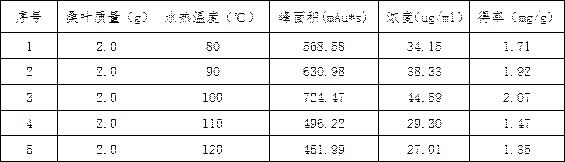

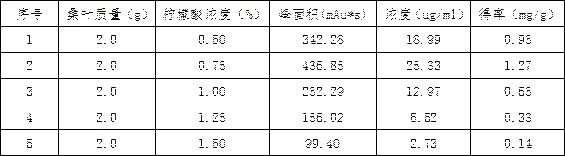

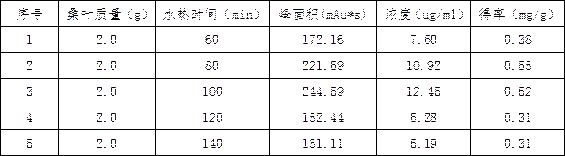

[0022] (2) Hydrothermal acid catalytic treatment of mulberry leaves

[0023] After the step (1) is completed, first weigh 2 g of the pretreated raw material obtained in the step (1) and place it in the hydrothermal reaction kettle, and then according to the ratio of the mass (g) of the raw material: the volume (ml) of the acid solution is 1 Add citric acid and ethanol aqueous solution in a ratio of 20:20, seal the reaction kettle after stirring, then put the hydrot...

Embodiment 2

[0027] A kind of DNJ method in mulberry leaf extraction with hydrothermal acid control alcohol, with embodiment 1, wherein:

[0028] In step (1), the oven temperature is 110°C, the oven time is 30 minutes, and the mesh number of mulberry leaves is 80 meshes.

[0029] In step (2), the ratio of the mass (g) of the raw material: the volume (ml) of the acid solution is 1:10, the reaction temperature is 80 °C, the reaction time is 100 min, the centrifugal speed is 2000 r / min, and the yield of DNJ is It is 0.54mg / g, the mass fraction of citric acid is 0.75%, and the volume fraction of ethanol solution is 60%.

[0030] In step (3), the retention time was 10.235 min, the purity of DNJ monomer was 41.0%, the mobile phase: methanol: water (30:70), the injection volume: 8 mL, and the flow rate: 15 mL / min.

Embodiment 3

[0032] A kind of DNJ method in mulberry leaf extraction with hydrothermal acid control alcohol, with embodiment 1, wherein:

[0033] In step (1), the oven temperature is 85°C, the oven time is 90 minutes, and the number of mulberry leaves is 100 meshes.

[0034] In step (2), the ratio of the mass (g) of the raw material: the volume (ml) of the acid solution is 1:15, the reaction temperature is 70 °C, the reaction time is 50 min, the centrifugation time is 10 min, and the DNJ yield is 0.89 mg / g, the mass fraction of citric acid was 0.5%, and the volume fraction of ethanol solution was 70%.

[0035] In step (3), the retention time was 15.893 min, the purity of DNJ monomer was 14.92%, mobile phase: methanol: water (20:80), injection volume: 5 mL, flow rate: 10 mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com