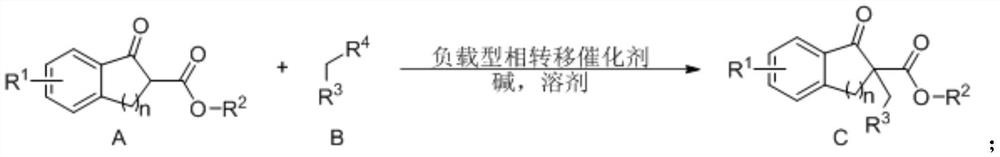

Method for realizing phase-transfer catalysis beta-dicarbonyl compound alkylation reaction by microchannel reactor

A dicarbonyl compound and microchannel reactor technology, which is applied in the preparation of organic compounds, chemical instruments and methods, chemical/physical/physical chemical reactors, etc., can solve the problems of difficult recovery and prolonged reaction time, and shorten the reaction time Effects of time, efficient recovery, stable scale-up and safe production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]

[0045] Add 10g SBA-15 (mesoporous molecular sieve), 5g tetrabutylammonium bromide (TBAB, quaternary ammonium salt) and 50mL toluene into a 100mL reaction flask, heat under reflux for 24h, remove toluene by vacuum distillation, and vacuum dry to obtain SBA-15-supported tetrabutylammonium bromide phase transfer catalyst 14.9 g (50% TBAB / SBA-15).

[0046] Disperse 0.310 g (1 mmol) 1-indanone-2-carboxylate adamantyl ester (A-1), 0.257 g (1.5 mmol) benzyl bromide (B-1), 0.03 g 50% TBAB / SBA-15 in 20 mL of toluene , an organic phase was obtained. A 1% KOH solution was prepared to obtain the aqueous phase. The flow rate of the organic phase was 5mL / min, and the flow rate of the aqueous phase was 5mL / min and passed into the microchannel reactor to carry out the alkylation reaction, the reaction temperature was 80°C, and the residence time was 30min to obtain 0.368g product (C-1, yield 92%). ). The reaction solution was filtered and washed with water to obtain a recovered...

Embodiment 7

[0055]

[0056] 10 g of chloromethylated polystyrene resin (PS, belonging to polystyrene resin), 1.2 g of tributylamine (Bu), 100 mL of dichloroethane and 50 mL of ethanol were added to a 250 mL reaction flask, and heated under reflux for 24 h. Filter and dry to obtain 11g PS grafted quaternary ammonium salt phase transfer catalyst (10%Bu / PS)

[0057] Disperse 0.345g (1mmol) of 5-chloro-1-indanone-2-carboxylate adamantate (A-2), 0.370g (2mmol) of m-methyl benzyl bromide (B-2), 0.069g of 10% Bu / PS In 20 mL of xylene, the organic phase was obtained. Formulated with 1% Na 2 CO 3 The solution gave an aqueous phase. The flow rate of the organic phase was 5mL / min, and the flow rate of the aqueous phase was 0.5mL / min and passed into the microchannel reactor to carry out the alkylation reaction. The reaction temperature was 60° C. and the residence time was 40min to obtain 0.386g of product (C-2, yield 86 %).

Embodiment 8

[0059]

[0060] Add 2g chloromethylated polystyrene resin (PS, belongs to polystyrene resin), 2.1g tetramethylpropylenediamine, 6g bromopropyltributylphosphonium bromide, and 100mL DMF into a 250mL reaction flask, and heat Reflux for 12h. Filter and dry to obtain 6.08 g of PS-grafted quaternary phosphonium salt phase transfer catalyst (300% P / PS).

[0061] 0.324g (1mmol) 4-methyl-1-indanone-2-carboxylate adamantyl ester (A-3), 0.717g (3mmol) p-trifluoromethyl benzyl bromide (B-3), 0.0648g 300%P / PS was dispersed in 20 mL of mesitylene to obtain an organic phase. Formulated 20% K 2 HPO 4 The solution gave an aqueous phase. The flow rate of the organic phase was 5mL / min, and the flow rate of the aqueous phase was 2.5mL / min and passed into the microchannel reactor to carry out the alkylation reaction, the reaction temperature was 100°C, and the residence time was 10min to obtain 0.429g product (C-3, yield 89 %).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com