Paste filling cementing material for tailings containing Zn and PAM as well as preparation method and application of paste filling cementing material

A paste filling and cementitious material technology, which is applied in the direction of filling, mining equipment, earth square drilling, etc., can solve the problems of reducing the formation of cement hydration products, which is not conducive to the development of early strength, and affects the development of early strength. Achieve high economic and environmental benefits, solve the effect of low early strength, and save filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

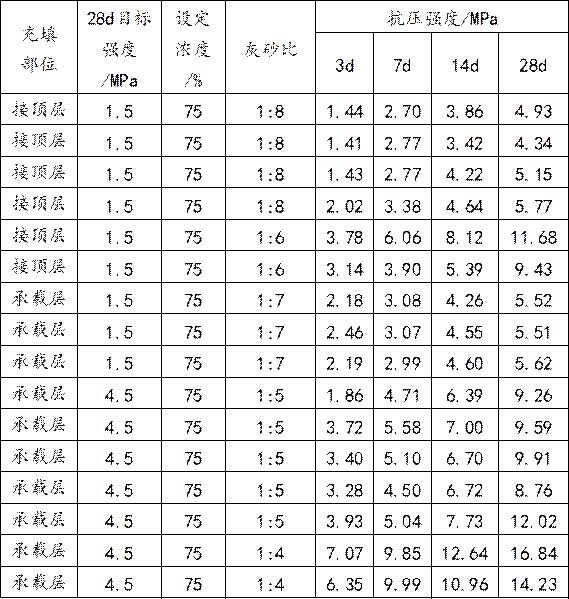

Examples

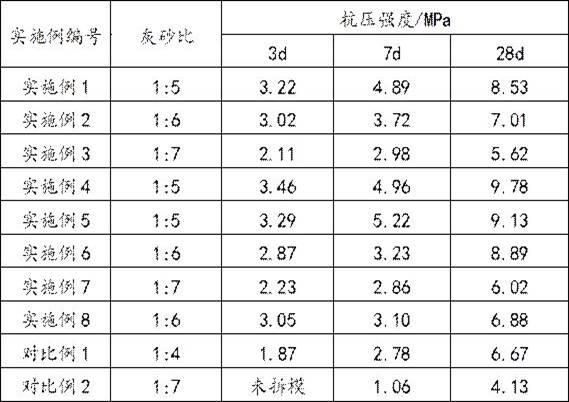

Embodiment 1

[0032] (1) Thoroughly dry the lead-zinc slag, and weigh 4.0kg of lead-zinc slag, 4.5kg of aluminate clinker, 0.7kg of industrial anhydrous aluminum sulfate and 0.8kg of slaked lime in proportion; put the lead-zinc slag into the mill The machine is firstly ground for 110 minutes, then put into aluminate clinker and then ground for 55 minutes, and finally put in industrial anhydrous aluminum sulfate and slaked lime for mixed grinding for 3 minutes; the specific surface area is not less than 400m after sieving. 2 The powder per kg is the paste filling cementitious material for tailings containing zinc and PAM.

[0033] (2) Weigh 1.6kg of the paste filling gelling material prepared above, mix it with 9.2kg of tailings containing Zn and PAM with a concentration of 87%, and add 2.0kg of water and stir to form a paste with a concentration of 75%. Filling slurry for molding; according to the curing conditions specified in the standard T / CECS 10091-2020 (temperature maintained at 20 °C...

Embodiment 2

[0035] (1) The lead-zinc slag is thoroughly dried, and 5.0kg of lead-zinc slag, 3.8kg of aluminate clinker, 0.5kg of industrial anhydrous aluminum sulfate and 0.7kg of quicklime are respectively weighed in proportion; the lead-zinc slag is put into the mill. The machine is firstly ground for 120 minutes, then put into aluminate clinker and then ground for 60 minutes, and finally put into industrial anhydrous aluminum sulfate and quicklime for mixed grinding for 5 minutes; the specific surface area after screening is not less than 400m 2 The powder per kg is the paste filling cementitious material for tailings containing Zn and PAM.

[0036] (2) Weigh 1.6kg of the paste filling gelling material prepared above, mix it with 11.0kg of tailings containing Zn and PAM with a concentration of 87%, and add 2.3kg of water and stir to form a paste with a concentration of 75%. Filling slurry for molding; according to the curing conditions specified in the standard T / CECS 10091-2020 (tempe...

Embodiment 3

[0038] (1) Thoroughly dry the lead-zinc slag, and respectively weigh 4.7kg of lead-zinc slag, 4.5kg of aluminate clinker, 0.3kg of industrial anhydrous aluminum sulfate and 0.5kg of slaked lime in proportion; put the lead-zinc slag into the mill. The machine is firstly ground for 115 minutes, then put into aluminate clinker and then ground for 60 minutes, and finally put in industrial anhydrous aluminum sulfate and slaked lime for mixed grinding for 4 minutes; the specific surface area is not less than 400m after sieving 2 The powder per kg is the paste filling cementitious material for tailings containing Zn and PAM.

[0039] (2) Weigh 1.6kg of the paste filling gelling material prepared above, mix it with 12.9kg of tailings containing Zn and PAM with a concentration of 87%, and add 2.6kg of water and stir to form a paste with a concentration of 75%. Filling slurry for molding; according to the curing conditions specified in the standard T / CECS 10091-2020 (temperature maintai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com