Composite modified red mud-based asphalt anti-aging agent, and preparation method and application thereof

A compound modification and anti-aging agent technology, which is applied in the direction of climate sustainability, on-site coagulation pavement, roads, etc., can solve problems such as aging problems, reduce road maintenance costs, improve comprehensive performance, The effect of prolonging service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

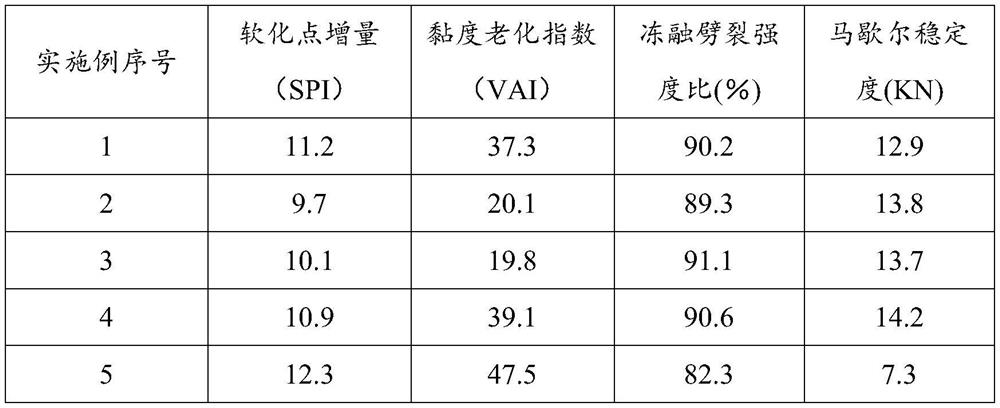

Examples

preparation example Construction

[0041] The second aspect of the present invention discloses the preparation method of the composite modified red mud-based asphalt anti-aging agent, comprising the following steps:

[0042] (1) Drying the red mud and the red mud modified material for subsequent use;

[0043] (2) pulverize the materials after drying in step (1), respectively, and then dry them again to obtain corresponding powders for use.

[0044] (3) After the nanomaterial is activated, it is co-dispersed in the solution with the coupling agent in proportion, and heated and refluxed after the dispersion.

[0045] (4) Mix the powders in steps (2) and (3) uniformly with the coupling agent and aromatic oil, and then obtain.

[0046] Further, in step (1), the red mud modified material is a mixture of red mud, slaked lime and montmorillonite.

[0047]Further, in step (1), the drying temperature is 100-150°C, and the time is 2-5h. The excess water in each material can be removed by drying, which is convenient fo...

no. 1 example

[0071] 1. A preparation method of a composite modified red mud-based asphalt anti-aging agent, comprising the following steps:

[0072] (1) The sintered red mud, slaked lime, montmorillonite, and cement were dried in a 100°C oven for 3 hours.

[0073] (2) The four kinds of dried raw materials in step (1) are respectively ball-milled in a ball mill for 20 minutes, and ground to the particle size required by the filler in "Technical Specification for Highway Asphalt Pavement Construction" (JTG F400-2004). The ball-milled powder was then placed in an oven at 100°C for 3 hours until dry.

[0074] (3) The nano-SiO 2 After activation at 400°C for 5h, disperse together with the silane coupling agent in a dewatered toluene solution (the silane coupling agent according to the mass percentage of each raw material: 5% of the silane coupling agent), ultrasonically disperse for 10min, and heat Reflux at 115°C until no droplets drip. After the reaction period, the reaction was stopped an...

no. 2 example

[0082] 1. A preparation method of a composite modified red mud-based asphalt anti-aging agent, comprising the following steps:

[0083] (1) The sintered red mud, slaked lime, montmorillonite and cement were dried in an oven at 150°C for 5 hours.

[0084] (2) The four kinds of dried raw materials in step (1) are respectively ball-milled in a ball mill for 50 minutes, and ground to the particle size required by the filler in "Technical Specification for Highway Asphalt Pavement Construction" (JTG F40-2004). Then, the ball-milled powder was placed in an oven at 150°C for 5 hours until dry.

[0085] (3) The nano-TiO 2 Activated at 400°C for 5 hours, and dispersed together with the titanate coupling agent in a dewatered toluene solution (the titanate coupling agent according to the mass percentage of each raw material: 5% of the titanate coupling agent) , ultrasonically dispersed for 10 min, heated at 110 °C and refluxed until no droplets were dropped. After the reaction period,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com