Electric heating fabric with pressure sensitive characteristic, preparation method of electric heating fabric, electric blanket and sitting and bedding

A pressure-sensitive technology, applied in the field of electric blankets, sitting and bedding, can solve problems such as waste of heat, waste, and increased energy consumption, and achieve the effects of saving electricity, reducing energy consumption, and reducing filling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

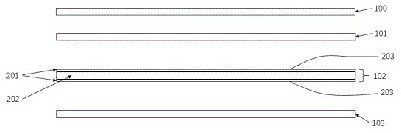

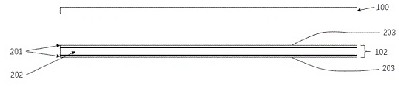

[0035] In some specific embodiments, the preparation method of the electric heating fabric with pressure-sensitive properties includes the following steps:

[0036] (1) Take two substances with a mass ratio of black phosphorus to metal oxide of 0.1-10 and place them in a ball mill filled with argon gas, and mill them at a speed of 500-1000r / min for 5-15h to obtain a particle size range of 10- 100nm black phosphorus / metal oxide composite;

[0037](2) In a glove box filled with inert gas, the black phosphorus / metal oxide nanocomposite was uniformly dispersed in deionized water after removing oxygen to obtain a dispersion with a concentration of 1-10 mg / ml; then the required mass The graphene is dispersed in the above-mentioned nanocomposite material dispersion liquid to obtain a graphene dispersion liquid with a concentration of 50-100mg / ml; an appropriate amount of solid content of 30-60% aqueous polyurethane emulsion is added to the above-mentioned dispersion liquid, and furth...

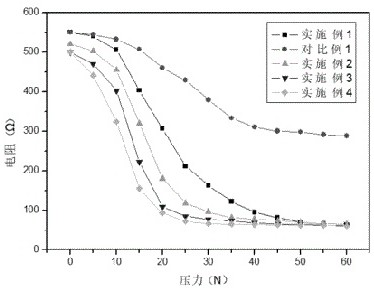

Embodiment 1

[0042] A preparation method of an electrothermal film with pressure-sensitive properties, comprising the steps of:

[0043] (1) Take two substances with a mass ratio of black phosphorus to nano-zinc oxide of 0.1, put them in a ball mill tank filled with argon, and grind them at a speed of 1000 r / min for 5 hours to obtain a black phosphorus / zinc oxide composite with a particle size range of 80 nm. Material;

[0044] (2) In a glove box filled with inert gas, the black phosphorus / zinc oxide nanocomposite was evenly dispersed in 100 ml of deionized water after removing oxygen to obtain a dispersion with a concentration of 1 mg / ml; Graphene is dispersed in the above-mentioned nano-composite material dispersion liquid to obtain a graphene dispersion liquid with a concentration of 50 mg / ml; 200 g of a 60% aqueous polyurethane emulsion with a solid content of 60% is added to the above-mentioned dispersion liquid, and further dispersed to obtain an aqueous slurry; The water-based slur...

Embodiment 2

[0050] (1) Take two substances with a mass ratio of black phosphorus and nano-alumina of 1:1, put them in a ball mill tank filled with argon, and grind them at a speed of 600r / min for 7h to obtain black phosphorus / oxidation with a particle size range of 100nm. Aluminum composite material;

[0051] (2) In a glove box filled with inert gas, the black phosphorus / alumina nanocomposite was uniformly dispersed in 100 ml of deionized water after removing oxygen to obtain a dispersion liquid with a concentration of 2 mg / ml; Graphene is dispersed in the above-mentioned nanocomposite material dispersion liquid to obtain a graphene dispersion liquid with a concentration of 60 mg / ml; 260 g of a 50% aqueous polyurethane emulsion with a solid content of 50% is added to the above-mentioned dispersion liquid, and further dispersed to obtain an aqueous slurry; The water-based slurry is applied by scraping, scraping a wet film with a thickness of 400 μm on the release film, and drying the wet f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com