Mesh spring ring and manufacturing method thereof

A technology of spring coils and mesh, which is applied in the field of mesh spring coils and its preparation, can solve the problems of heavy weight, compression, and low filling rate of spring coils, etc., and achieve low filling rate, weight reduction, and enhanced embolization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

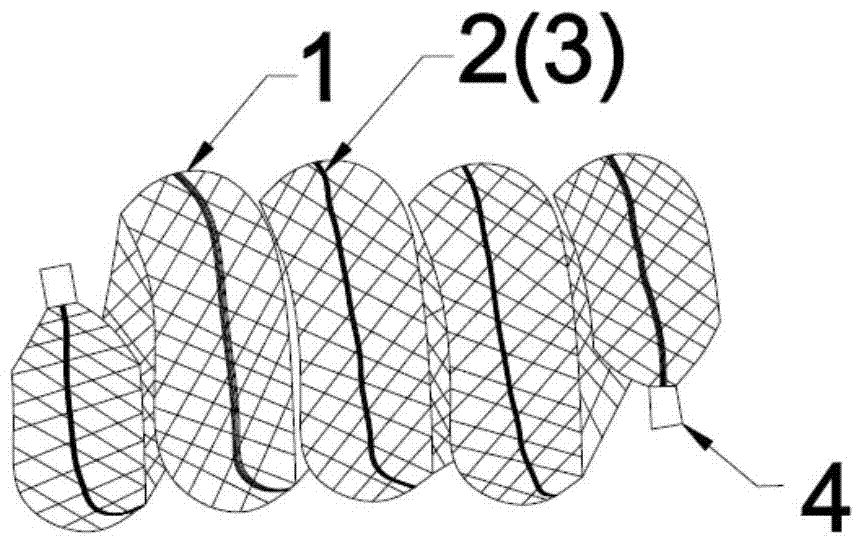

[0039] The invention provides a method for preparing a mesh spring coil, comprising:

[0040] The metal mesh pipe is prepared by using memory alloy as raw material;

[0041] heat treating the metal mesh pipe to obtain a metal mesh sleeve;

[0042] Fix the spring, metal core and metal mesh sleeve;

[0043] The metal mesh sleeve is sheathed on the outside of the spring, and the inner diameter of the metal mesh sleeve is larger than the outer diameter of the spring; the metal core is arranged through the inside of the spring.

[0044] In the present invention, firstly, the memory alloy is used as a raw material to prepare a metal mesh pipe; the metal mesh pipe is heat-treated to obtain a metal mesh sleeve. The present invention is preferably prepared by a weaving method; the preparation method of the metal mesh sleeve preferably specifically includes: weaving a memory alloy as a raw material to obtain a metal mesh tube; assembling the woven mesh tube on a mold, and shaping it i...

Embodiment 1

[0053] 60 nickel-titanium alloy wires (54.5% nickel, 45.5% titanium) with a diameter of 0.05mm are used to weave the network tube, and the network tube density is 100PPI (Per Point Inch, the number of crossing points per inch); the woven network tube is installed in the heat treatment molding On the mold, it is set into a spiral shape, the heat treatment temperature is 400 ° C, and the heat treatment time is 35 minutes, and the diameter of the net sleeve obtained is 1 mm; the spring is prepared by platinum alloy wire with a diameter of 0.04 mm, and the diameter of the spring is 0.2 mm; the pitch is 0.2 mm ;Put a platinum alloy with a diameter of 0.15mm and a length of 100mm as a metal core and place it inside the spring; place the spring together with the metal core inside the metal mesh sleeve, and use titanium alloy with an inner diameter of 0.2mm and an outer diameter of 0.25 mm, a metal ring 4 with a width of 0.3mm is used to fix the metal mesh sleeve 1, spring 2, and metal...

Embodiment 2

[0055] Use 40 nickel-titanium alloy wires (55% nickel, 45% titanium) with a diameter of 0.1mm to weave the network tube, and the network tube density is 65PPI (Per Point Inch, the number of intersections per inch); the woven network tube is installed in the heat treatment molding The mold is set in a spiral shape, the heat treatment temperature is 500°C, and the heat treatment time is 20 minutes, so that the diameter of the net sleeve is 3mm; the polyvinylpyrrolidone is coated on the surface of the nickel-titanium wire by spraying, and the thickness is 0.01mm. Use platinum wire with a diameter of 0.1mm to prepare the spring, the diameter of the spring is 0.3mm; the pitch is 0.3mm; a gold alloy with a diameter of 0.2mm and a length of 200mm is inserted inside the spring as a metal core; place the spring together with the metal core Inside the metal mesh sleeve, a metal ring 4 made of platinum alloy, with an inner diameter of 0.5mm, an outer diameter of 1.0mm, and a width of 1.0m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com