Bone fracture plate for ulna and radius shaft

A bone plate and backbone technology, applied in the field of medical devices, can solve the problems that it is not easy to determine the diameter of the screw path just in the bone section, increase the forearm compartment syndrome, and the low stress demand of the ulna and radius, etc., to achieve the benefit of screw double Double cortex fixation, beneficial to double cortex fixation, and the effect of reducing the probability of complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

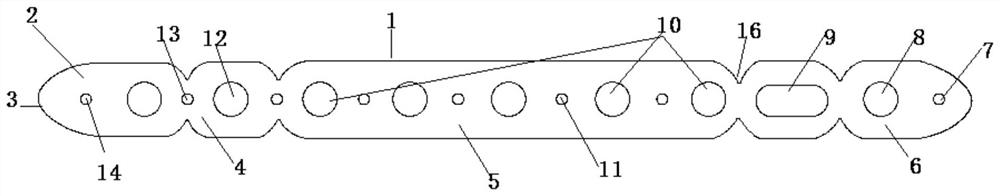

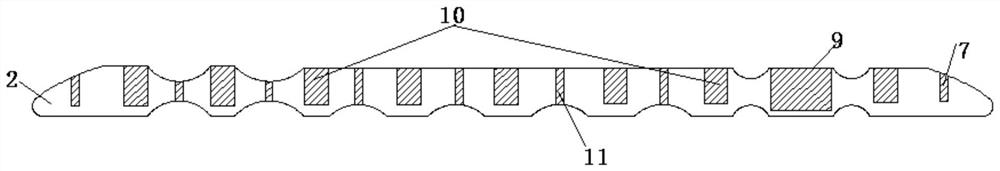

[0019] Such as Figure 1-Figure 4 A radial and ulna bone bone plate shown includes a bone plate body 1, the bone plate body 1 is in the shape of a strip, with a length of 6-20 cm, a width of 1-1.2 cm, and a thickness of 2.0-3.0 mm. The cross-section of the bone plate body 1 is an arc-shaped surface, and the two sides are curved toward the middle. The plate body 1 is divided into a proximal joint section 4, a middle section 5 and a distal joint section 6. The distal joint section 6 is provided with a distal Kirschner wire hole 7, a distal locking hole 8 and a sliding hole 9 in sequence. The end Kirschner wire holes 7 are located at the end of the distal joint section 6, and the middle section 5 is provided with a plurality of intermediate locking holes 10, and intermediate Kirschner wire holes 11 are arranged between adjacent intermediate locking holes 10, and the proximal A plurality of proximal locking holes 12 and proximal upper Kirschner wire holes 13 are opened on the joi...

Embodiment 2

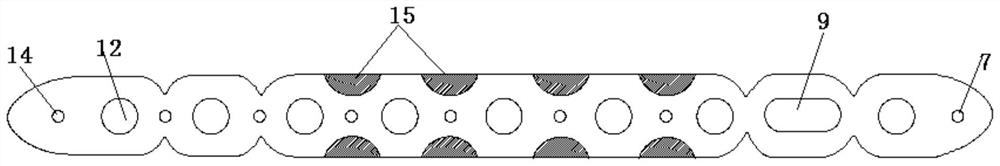

[0021] Such as Figure 1-Figure 4 A bone plate for the ulnar and radial shafts shown includes a bone plate body 1, the bone plate body 1 is elongated, and the edge is a smooth arc surface structure, which reduces the stimulation of the bone plate body 1 to the surrounding soft tissue. The body 1 has a length of 6-20cm, a width of 1-1.2cm, and a thickness of 2.0-3.0mm. The end is a shuttle-shaped structure 2, the end surface of the shuttle-shaped structure 2 is a smooth arc 3, the bone plate body 1 is divided into a proximal joint segment 4, a middle segment 5 and a distal joint segment 6, the bone plate body 1 There are multiple arc-shaped grooves 15 on the back, and the arc-shaped grooves 15 are symmetrically distributed on both sides of the middle section 5, so as to reduce the compression of the bone plate body 1 on the periosteum without affecting the strength of the bone plate body 1. To avoid damage to the blood supply, the distal joint segment 6 is sequentially provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com