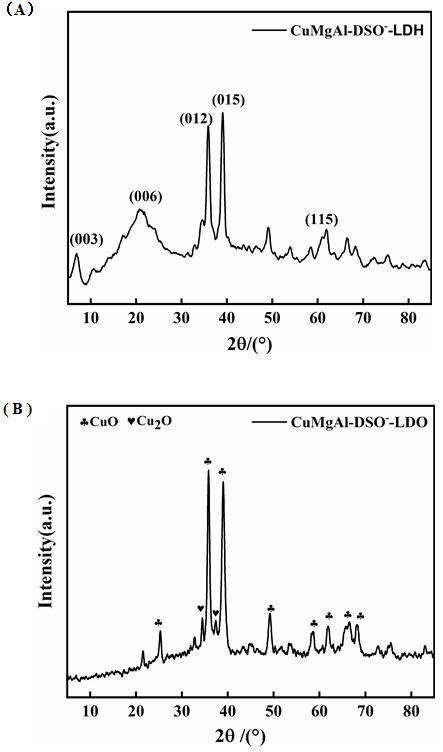

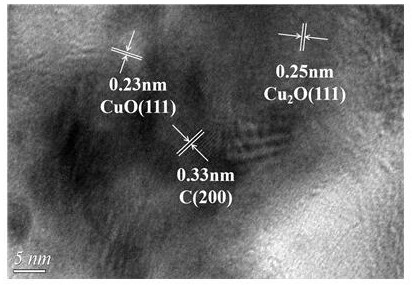

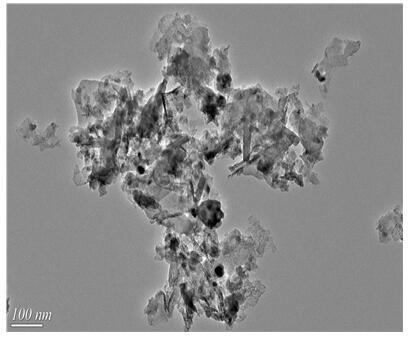

Preparation method and application of hydrotalcite-based carbon-doped copper-magnesium-aluminum composite oxide catalyst

A hydrotalcite-based, aluminum composite technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the high cost of carbon nanotubes and the modification process of carbon tubes. It can improve the anti-sulfur performance, slow down the poisoning effect, and improve the activity effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Take 30 ml respectively and the concentration is 0.5 mol·L -1 Aqueous solution of aluminum nitrate nonahydrate, 30 ml concentration is 0.5mol·L -1 Aqueous solution of magnesium nitrate hexahydrate and 30 ml with a concentration of 1.0 mol L -1 The prepared aqueous solution of copper nitrate trihydrate was placed in a beaker, stirred with a magnetic stirrer for 10 min to make it evenly mixed, and the prepared salt solution was transferred to a dropping funnel for use;

[0037] (2) Take 300 ml as a concentration of 1.00 mol L -1 The sodium hydroxide aqueous solution is transferred to the dropping funnel for use;

[0038] (3) Take 90 ml as 0.2 mol L -1 The sodium dodecyl sulfonate solution is placed in a four-necked flask, and the sodium hydroxide aqueous solution and the mixed salt solution are simultaneously dropped into the above solution under magnetic stirring, and the pH value in the titration process is monitored in real time with an acidity meter to control th...

Embodiment 2

[0043] (1) Take 30 ml respectively and the concentration is 0.5 mol·L -1 Aqueous solution of aluminum nitrate nonahydrate, 0.5 mol L in 60 ml -1 Aqueous solution of magnesium nitrate hexahydrate and 15 ml with a concentration of 1.0 mol L -1 The prepared aqueous copper nitrate trihydrate solution was placed in a four-necked flask, and stirred for 10 min with a magnetic stirrer to make it evenly mixed, and the prepared salt solution was transferred to a dropping funnel for use;

[0044] (2) Take 300 ml as a concentration of 1.00 mol L -1 The sodium hydroxide aqueous solution is transferred to the dropping funnel for use;

[0045] (3) Take 45 ml as 0.4 mol L -1 The sodium dodecyl sulfonate solution is placed in a four-necked flask, and the sodium hydroxide aqueous solution and the mixed salt solution are simultaneously dropped into the above solution under magnetic stirring, and the pH value in the titration process is monitored in real time with an acidity meter, and the tit...

Embodiment 3

[0050] (1) Take 30 ml respectively and the concentration is 0.5 mol·L -1 Aqueous solution of aluminum nitrate nonahydrate, 60 ml concentration is 0.5mol·L -1 Aqueous solution of magnesium nitrate hexahydrate and 30 ml with a concentration of 1.0 mol L -1 The prepared aqueous copper nitrate trihydrate solution was placed in a four-necked flask, and stirred for 10 min with a magnetic stirrer to make it evenly mixed, and the prepared salt solution was transferred to a dropping funnel for use;

[0051] (2) Take 300 ml as a concentration of 1.00 mol L -1 The sodium hydroxide aqueous solution is transferred to the dropping funnel for use;

[0052] (3) Take 60 ml as 0.4 mol L -1 The sodium dodecyl sulfonate solution is placed in a beaker, and the sodium hydroxide aqueous solution and the mixed salt solution are dropped into the above solution at the same time under magnetic stirring, and the pH value in the titration process is monitored in real time with an acidity meter, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com