Method for enhancing interface heat transfer between metal material and organic material

A technology of metal materials and organic materials, which can be used in metal material coating processes, chemical instruments and methods, heat exchange materials, etc., and can solve the problems of limited effect of interface strengthening heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

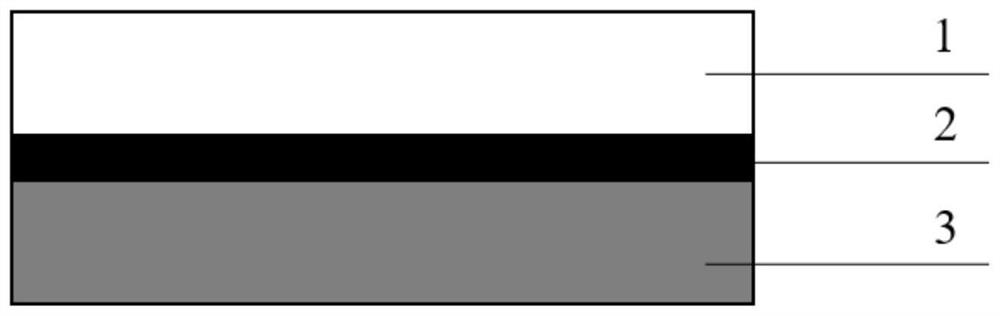

[0042] like figure 1 As shown, a sandwich structure material is provided, which is in the form of a flat plate, including a metal material 1, an electro-acoustic coupling material 2 and an organic material 3; the electro-acoustic coupling material 2 is in the middle of the metal material 1 and the organic material 3. .

[0043] Wherein, the electro-acoustic coupling material 3 is liquid metal gallium.

[0044] The metal material 1 can be pure metals such as copper, iron, nickel and their alloys;

[0045] The organic material 3 can be high molecular polymer, silicone oil, etc.;

[0046] The metal material 1 is connected with the electro-acoustic coupling material 2 by metal bonds or van der Waals force; specifically, the metal material 1 can be immersed in the electro-acoustic coupling material 2 and then placed in a high-temperature furnace for 10 minutes, so that the two A metal bond is formed at the interface of the metal material 1; the electro-acoustic coupling material...

Embodiment 2

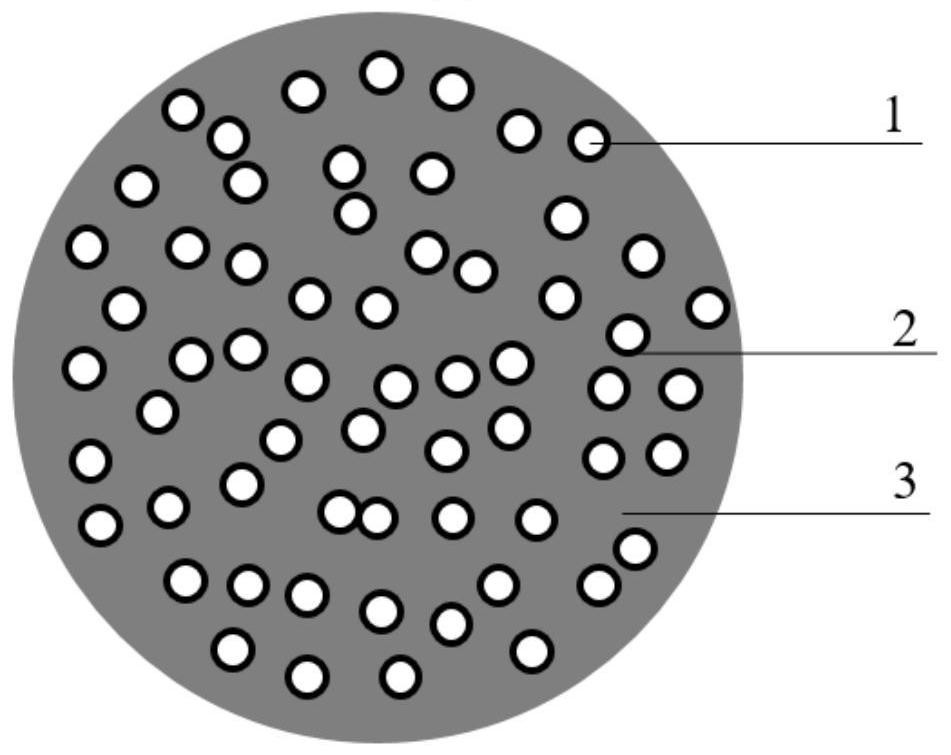

[0050] like figure 2 As shown, the metallic material is dispersed in the organic material matrix, including metallic material 1 , electro-acoustic coupling material 2 and organic material 3 . In this embodiment, the electro-acoustic coupling material 2 is first attached to the surface of the metal material 1 , and then the metal material 1 is dispersed in the organic material 3 . The material selection and connection method are the same as those in the first embodiment.

Embodiment 3

[0052] 1. Preparation of copper powder / gallium indium / polydimethylsiloxane composites

[0053] First, immerse 20g copper powder (800 mesh) in 30mL, 1mol / L hydrochloric acid for 10 minutes at room temperature to remove the surface oxide layer; then, pour 110g gallium indium alloy into the solution and stir at room temperature for 10 minutes to make A layer of liquid metal was plated on the surface of the copper powder; then the mixture of liquid metal and copper powder was taken out and dried to completely remove the moisture; the dried mixture was added to 21 g of polydimethylsiloxane, stirred thoroughly for 10 minutes, and placed After evacuating in a vacuum drying oven for 30 minutes, it was heated at 120° C. for 2 hours for curing.

[0054] 2. Preparation of copper powder / polydimethylsiloxane composites

[0055] At room temperature, soak 89g copper powder (800 mesh) in 50mL, 1mol / L hydrochloric acid for 10 minutes to remove the surface oxide layer; then take out the copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com