Formaldehyde-free flame-retardant magnesium oxychloride cement-based wood adhesive and preparation method thereof

A technology of adhesives and lightly burned magnesia, applied in adhesives, inorganic adhesives, adhesive additives, etc., can solve problems such as poor water resistance, fire hazards, and formaldehyde pollution of magnesium oxychloride cement-based adhesives, and achieve Solve the problems of formaldehyde pollution and fire hazards, no formaldehyde release, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides an adhesive comprising components of the following weight: lightly burned magnesium oxide 106 parts, magnesium chloride hexahydrate 64 parts, water 40 parts, biochar 5.25 parts.

[0042] The present embodiment also provides a method for preparing the above adhesive: comprising the following steps:

[0043] (1) Disperse magnesium chloride hexahydrate in water and stir evenly at room temperature;

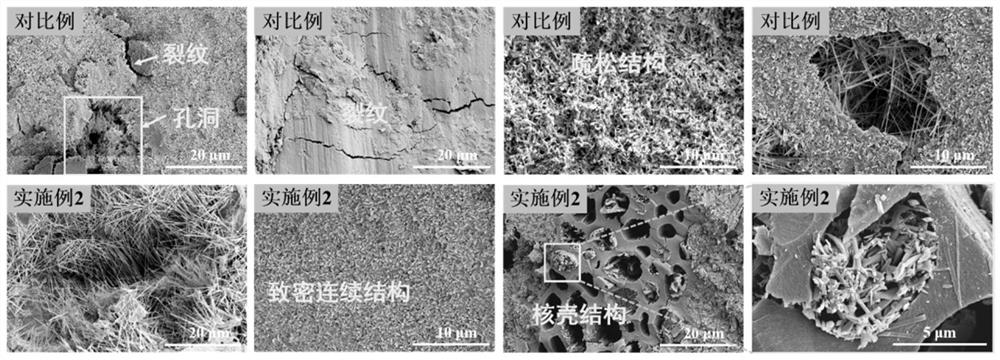

[0044] (2) The lightly burned magnesium oxide and biochar are slowly added to the dispersion obtained in step (1), and stirred evenly at room temperature to obtain a magnesium oxychloride cementitious adhesive with a porous structure of cuttlefish bone.

Embodiment 2

[0046] The present embodiment provides an adhesive comprising components of the following weight: lightly burned magnesium oxide 106 parts, magnesium chloride hexahydrate 64 parts, water 40 parts, biochar 10.5 parts.

[0047] The present embodiment also provides a method for preparing the above adhesive: comprising the following steps:

[0048] (1) Disperse magnesium chloride hexahydrate in water and stir evenly at room temperature;

[0049] (2) The lightly burned magnesium oxide and biochar are slowly added to the dispersion obtained in step (1), and stirred evenly at room temperature to obtain a magnesium oxychloride cementitious adhesive with a porous structure of cuttlefish bone.

Embodiment 3

[0051] The present embodiment provides an adhesive comprising components of the following weight: lightly burned magnesium oxide 106 parts, magnesium chloride hexahydrate 64 parts, water 40 parts, biochar 15.75 parts.

[0052] The present embodiment also provides a method for preparing the above adhesive: comprising the following steps:

[0053] (1) Disperse magnesium chloride hexahydrate in water and stir evenly at room temperature;

[0054] (2) The lightly burned magnesium oxide and biochar are slowly added to the dispersion obtained in step (1), and stirred evenly at room temperature to obtain a magnesium oxychloride cementitious adhesive with a porous structure of cuttlefish bone.

PUM

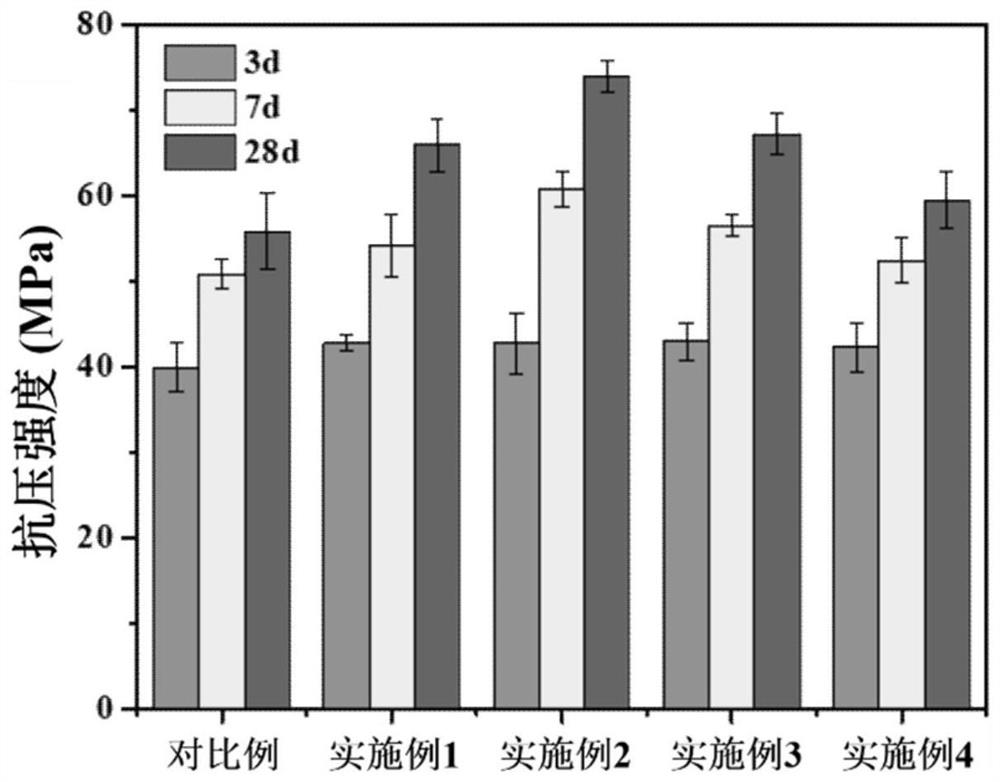

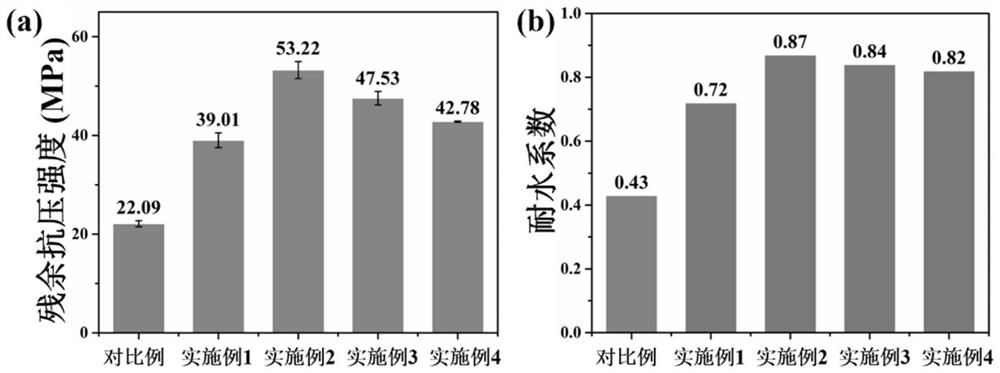

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water resistance coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com