Amorphous silicon-based material and preparation method and application thereof

A base material, amorphous silicon technology, applied in the field of biomedical hemostatic materials, can solve the problems of high preparation cost, easy to form waste water, less blood loss in mice, etc., and achieve effective hemostatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This embodiment prepares an amorphous silicon-based material, and the specific preparation method is as follows:

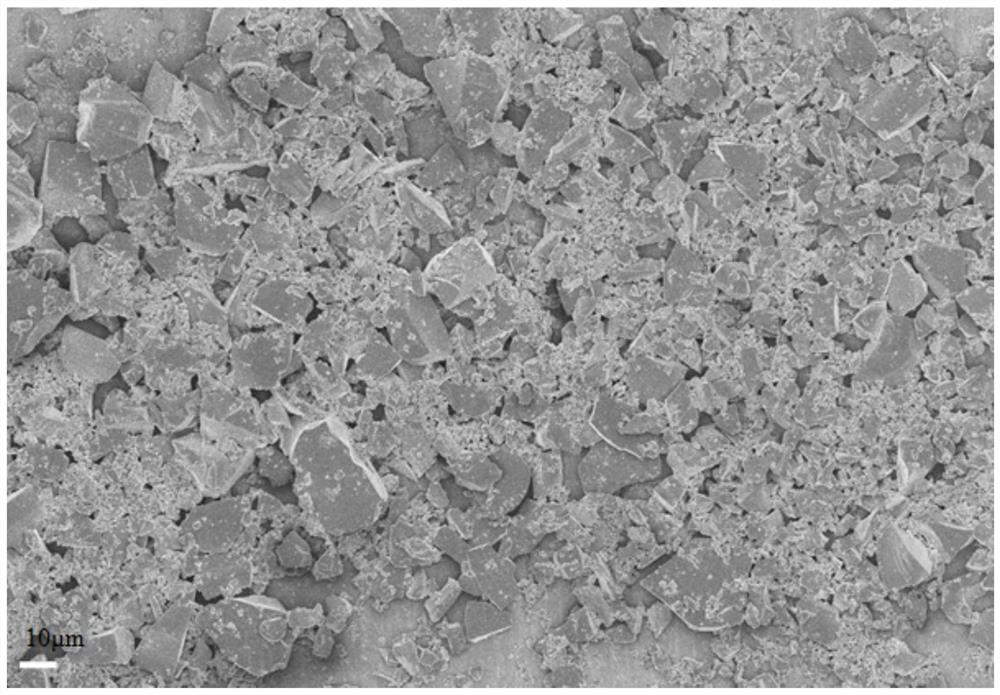

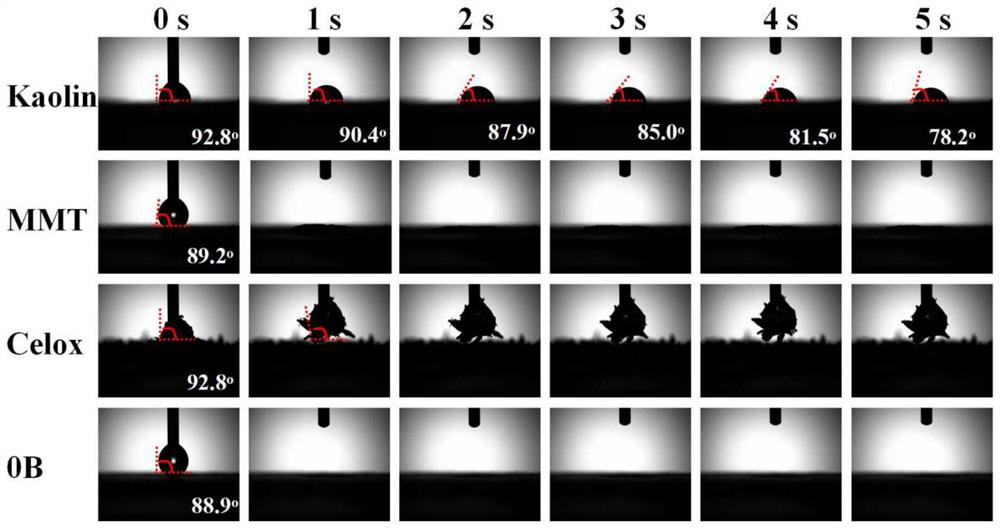

[0075] Weigh 142.48g SiO 2 , 54.18g CaO, 34.12g (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O, 14.5g NaH 2 PO 4 ·2H 2 O, 12.96g anhydrous Na 2 CO 3 , 24.28g anhydrous K 2 CO 3 Place in a ceramic jar and mix well with a ternary mixer. Add the mixed powder into a platinum crucible, keep it at 1400 °C for 20 minutes to melt, then quench the glass water on a cold steel plate, and finally perform ball milling with a planetary ball mill with a ball-to-material ratio of 4:1, ball milling for 2 hours, vibrating screen The sieve is carried out by the analyzer to obtain the amorphous silicon-based material of the present invention (hereinafter referred to as OB) of the micron scale. Depend on figure 1 SEM image of 0B material. figure 2 It is the appearance diagram of 0B material.

Embodiment 2

[0077] This embodiment prepares an amorphous silicon-based material, and the specific preparation method is as follows:

[0078] Accurately weigh 106.63g SiO 2 , 37.68g H 3 BO 3 , 96.50g CaCO 3 , 20.45g Mg(OH) 2 , 42.25gSrCO 3 , 13.67g NaH 2 PO 4 ·2H 2 O, 13.93g anhydrous Na 2 CO 3 , 16.51g anhydrous K 2 O placed in a ceramic jar and mixed well with a ternary mixer. Add the mixed powder into a platinum crucible, keep it at 1300°C for 20 minutes to melt, then quench the glass water on a cold steel plate, and finally perform ball milling with a planetary ball mill with a ball-to-material ratio of 3:1, ball milling for 4 hours, vibrating screen The sieve is carried out by the analyzer to obtain the amorphous silicon-based material of the present invention (hereinafter referred to as 1B) in the micrometer scale.

Embodiment 3

[0080] This embodiment provides an amorphous silicon-based material, and the specific preparation method is:

[0081] Accurately weigh 77.40g SiO 2 , 164.09g H 3 BO 3 , 56.56g Ca(OH) 2 , 37.07g (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O, 45.25g SrCO 3 , 29.77g NaH 2 PO4 ·2H 2 O, 4.05g anhydrous Na 2 CO 3 , 26.37g anhydrous K 2 CO 3 Place in a ceramic jar and mix well with a ternary mixer. Add the mixed powder into a platinum crucible, keep at 1200 °C for 20 minutes to melt, then quench the glass water on a cold steel plate, and finally perform ball milling with a planetary ball mill with a ball-to-material ratio of 2:1, ball milling for 6 hours, vibrating screen The micrometer-scale borosilicate bioactive glass material (hereinafter referred to as 2B) is obtained by sieving through the analyzer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com