Self-repairing and self-lubricating difunctional microcapsule as well as preparation method and application thereof

A self-healing, dual-function technology, applied in the direction of microcapsule preparation, microsphere preparation, coating, etc., can solve environmental burden and other problems, and achieve excellent self-healing and self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

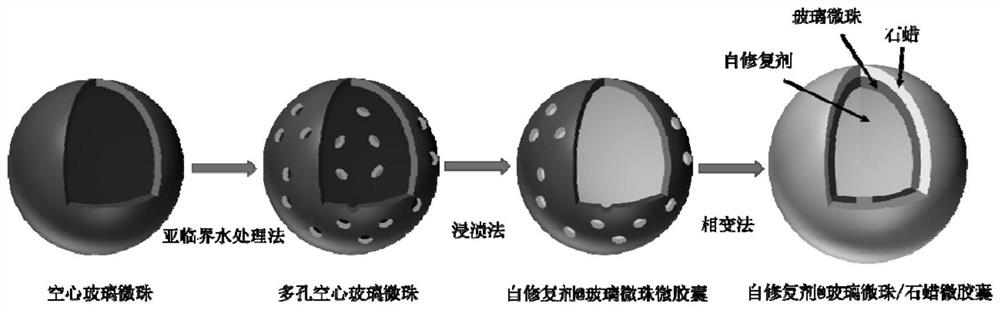

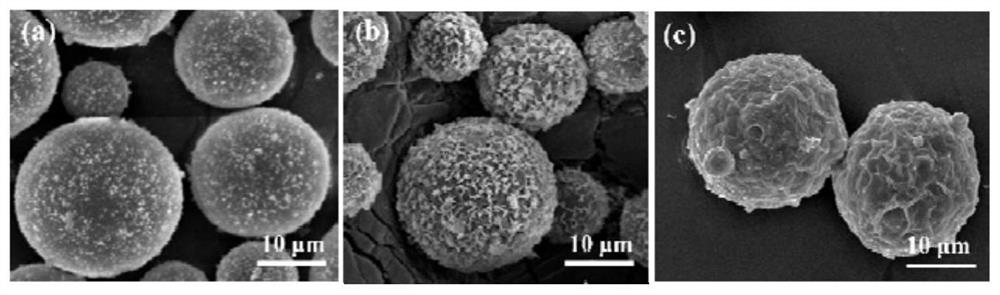

[0073] 1 g of hollow glass microspheres with an outer diameter of 20 μm and an inner diameter of 18 μm (see figure 2 Figure (a)) and 40mL (0.1mol / L) sodium hydroxide aqueous solution were added to the reaction kettle, and the temperature was raised to 250°C in a closed state. After maintaining this temperature for 2 hours, the reaction kettle was naturally cooled to room temperature, filtered, and removed. Porous hollow glass microspheres were obtained after washing with ion water and drying.

[0074] Disperse 1g of porous hollow glass microspheres into 10g of linseed oil as a self-healing agent, ultrasonically disperse for 20min with an ultrasonic power of 180W, put it in a vacuum oven at a temperature of 50°C and a vacuum of 0.06MPa for 30min, and then in air Place it for 12h, filter and wash off the linseed oil on the outer surface of the glass beads with ethyl acetate solvent to obtain self-healing agent@glass beads microcapsules (see figure 2 Figure (b)).

[0075] Mel...

preparation example 2

[0077] The method is basically the same as that of Preparation Example 1, except that isocyanate is used instead of linseed oil as the self-healing agent.

preparation example 3

[0079] The method is basically the same as that of Preparation Example 1, except that epoxy resin is used instead of linseed oil as the self-healing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com