Method for manufacturing perovskite layer at high speed

A perovskite, multi-layer substrate technology, used in the manufacture of perovskite layers and perovskite photovoltaic devices, the composition of perovskite solutions, the field of high-speed manufacturing of photovoltaic devices, to achieve low equipment cost, convenient handling and storage temperature, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

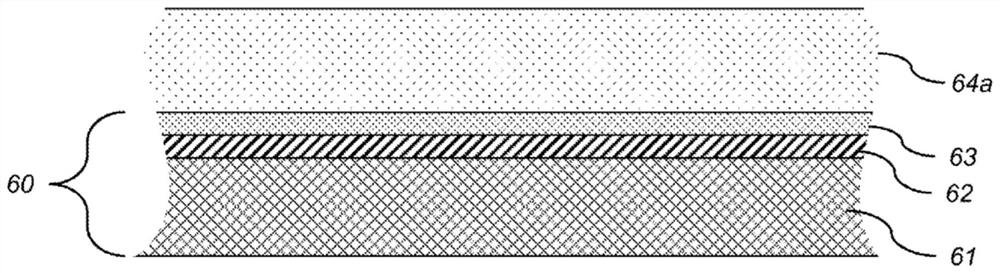

Embodiment 1

[0057] A flexible multilayer substrate with a width of 25.4 cm was conveyed through an R2R deposition and drying equipment manufactured by Polytype Converting for 3 trials at constant speeds of 30, 32 and 35 meters per minute. The Polytype Converting machine was modified as described below to implement the multi-step drying method of the present disclosure. The R2R deposition and drying equipment has an in-line arrangement for conveying the continuous flexible substrate from the unwind roll through the following sections: surface treatment equipment, deposition and first drying step section, second drying step fast drying section and long duration heating section. Flexible multilayer substrates with perovskite layers are wound on rewind rolls. The flexible multilayer substrate has a polyester film as a flexible support, a thin layer of indium tin oxide as a first conductive layer, and poly(triarylamine) as a first carrier transport layer. The surface treatment equipment is a ...

Embodiment 2

[0060] A flexible multilayer substrate with a width of 15.2 cm was conveyed through a R2R deposition and drying apparatus manufactured by Eastman Kodak Co. at constant speeds of 11.9, 12.2, 12.5, 12.8, 13.1, and 13.4 meters per minute for six trials. The R2R machine was modified as described below to implement the multi-step drying method of the present disclosure. The R2R deposition and drying apparatus has a tandem arrangement for conveying a continuous flexible substrate from an unwind roll through the following sections: a deposition and first drying step section, a second drying step taking place in a fast drying section, and a long duration heating section. Flexible multilayer substrates with perovskite layers are wound on rewind rolls. The flexible multilayer substrate has a polyester film as a flexible support, a thin layer of indium tin oxide as a first conductive layer, and poly(triarylamine) as a first carrier transport layer. In the deposition part, a 4.5 μm thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com