Construction method and construction equipment for additionally paving thin overlay structure on bridge floor

A thin-layer overlay and construction method technology, applied in bridge construction, bridge reinforcement, bridge and other directions, can solve the problems of unsatisfactory mixing effect, insufficient anti-skid performance, low work efficiency, etc., and achieve good construction process time, shear resistance With high bonding strength, the effect of improving the application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A construction method for adding a thin layer of overlay structure to the bridge deck, including the following steps:

[0071] S1、Preparation:

[0072] S11. Formulate effective treatment measures according to the characteristics and causes of different diseases and damages of the bridge deck, and carry out damage repair and pretreatment of the original bridge deck;

[0073]S12. Traffic closure of the construction section and the installation of construction safety signs;

[0074] S13. Sweep the road surface of the construction section, prohibit pedestrians and vehicles from passing, and ensure the safety and quality of the construction;

[0075] S2, thin layer construction:

[0076] S21, the use of milling machine to the bridge deck for 1-1.5cm fine milling, all diseases after repair and clean up;

[0077] S22, the use of epoxy resin and No. 70 A grade road petroleum asphalt mixed in the ratio of 4-5:5-6 to make secondary curing epoxy asphalt as a waterproof bonding layer;...

Embodiment 2

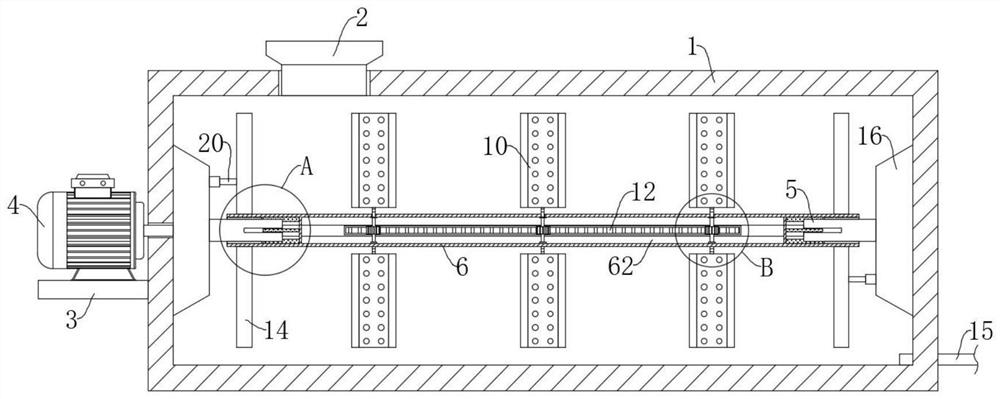

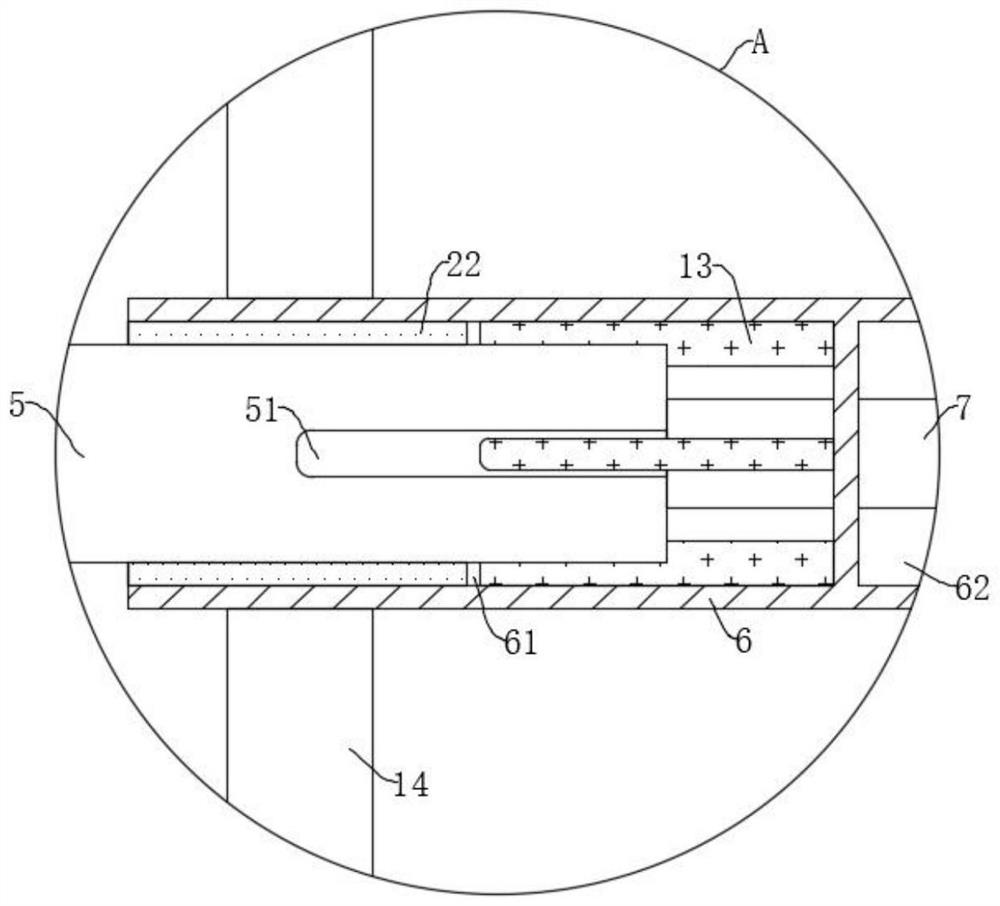

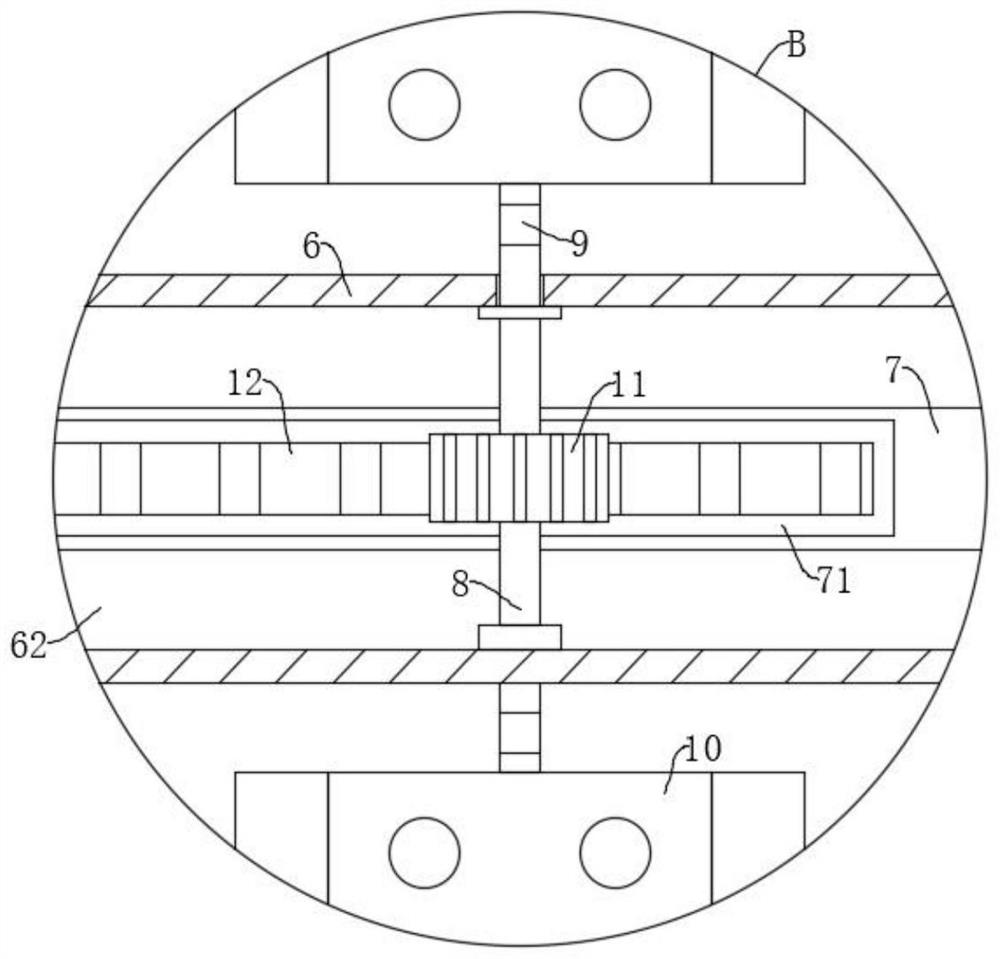

[0147] The present embodiment as a further improvement of the previous embodiment: reference Figure 1-11 , a kind of bridge deck plus a thin layer of overlay structure of the construction equipment, including a stirring device for the construction of mixing, the mixing device comprises a tank 1, the top of the tank 1 is provided with an inlet hopper 2, the bottom of one side of the tank 1 is provided with an outlet pipe 15, the other end of the discharge pipe 15 is connected to the external discharge equipment, the outer wall of the tank 1 is fixed with a horizontal plate 3, the top of the horizontal plate 3 is fixed with a mixing motor 4, and the inner wall of the side of the tank 1 is symmetrically rotated away from each other and connected to two rotary rods 5, And the output shaft of the stirring motor 4 runs through one side of the tank 1 and is fixedly connected to one of the ends of one of the rotary rods 5, the outer wall sliding sleeve of the two rotary rods 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com