Preparation process of inorganic ecological stone capable of keeping high luminosity and inorganic ecological stone

A preparation process and ecological stone technology, applied in the direction of manufacturing tools, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problems of low gloss of inorganic ecological stone, affecting product appearance, dust generation, etc., to achieve increased Long-lasting decorative effect, increased gloss retention and waterproof performance, and the effect of avoiding subtle chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

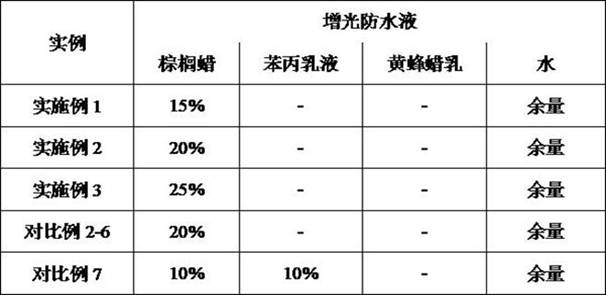

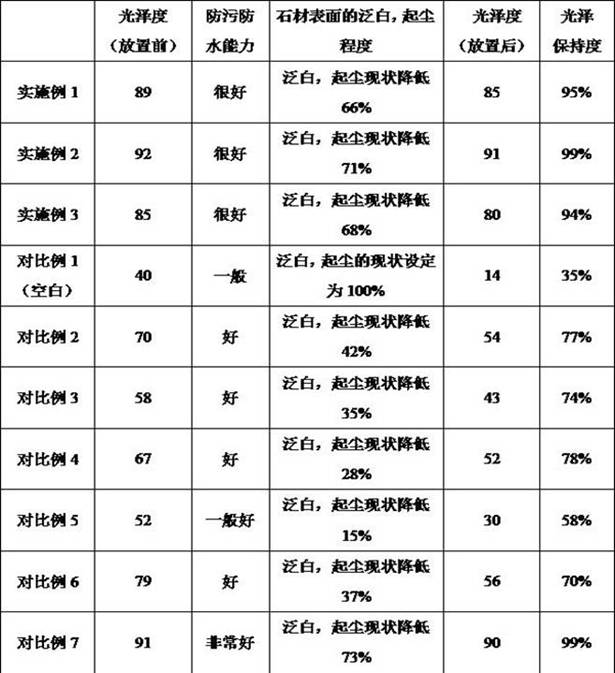

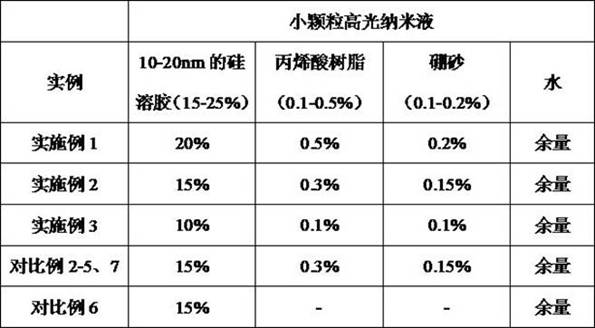

Embodiment 1-3 and comparative example 1-7

[0060] Take the same batch of inorganic ecological stones produced by a certain company on the market, and perform high-gloss surface treatment on the above-mentioned inorganic ecological stones according to the preparation processes of Examples 1-3 and Comparative Examples 1-7 respectively.

Embodiment 1

[0062] A preparation process for inorganic ecological stones maintaining high luminosity, comprising the following steps:

[0063] (1) Filling steps of large particle pretreatment liquid:

[0064] Use grinding equipment to pre-polish and grind the surface of the inorganic ecological stone to make the surface of the inorganic ecological stone smooth, clean the debris on the surface of the inorganic ecological stone, and preheat the inorganic ecological stone at a temperature of 55 ° C; with the help of the inorganic ecological stone temperature, drop the large particle pretreatment liquid I into and coat the surface of the inorganic ecological stone, the amount of the large particle pretreatment liquid I is 10g / m 2 , the dripping time of the large particle pretreatment I liquid is controlled at 5s, the grinding and coating time is 30s, the revolution speed of the grinding disc of the grinding equipment is 90r / min, and the rotation speed of the abrasive material installed on the...

Embodiment 2

[0070] A preparation process for inorganic ecological stones maintaining high luminosity, comprising the following steps:

[0071] (1) Filling steps of large particle pretreatment liquid:

[0072] Use grinding equipment to pre-polish and grind the surface of the inorganic ecological stone to make the surface of the inorganic ecological stone smooth, clean the debris on the surface of the inorganic ecological stone, and preheat the inorganic ecological stone at a temperature of 60°C; temperature, drop the large particle pretreatment I liquid and coat it on the surface of the inorganic ecological stone, the amount of the large particle pretreatment I liquid is 13g / m 2, the dripping time of the large particle pretreatment I liquid is controlled at 6s, the grinding and coating time is 40s, the revolution speed of the grinding disc of the grinding equipment is 115r / min, and the rotation speed of the abrasive installed on the grinding disc is 1000r / min, so that it can penetrate into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com