Mullite fiber reinforced metal-based composite ceramic sheet and preparation method thereof

A metal matrix composite, mullite fiber technology, applied in the production of ceramic materials and other directions, can solve the problem of uneven dispersion of self-growing substances, and achieve the effect of improving mechanical structure stability, high reactivity, and avoiding material failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

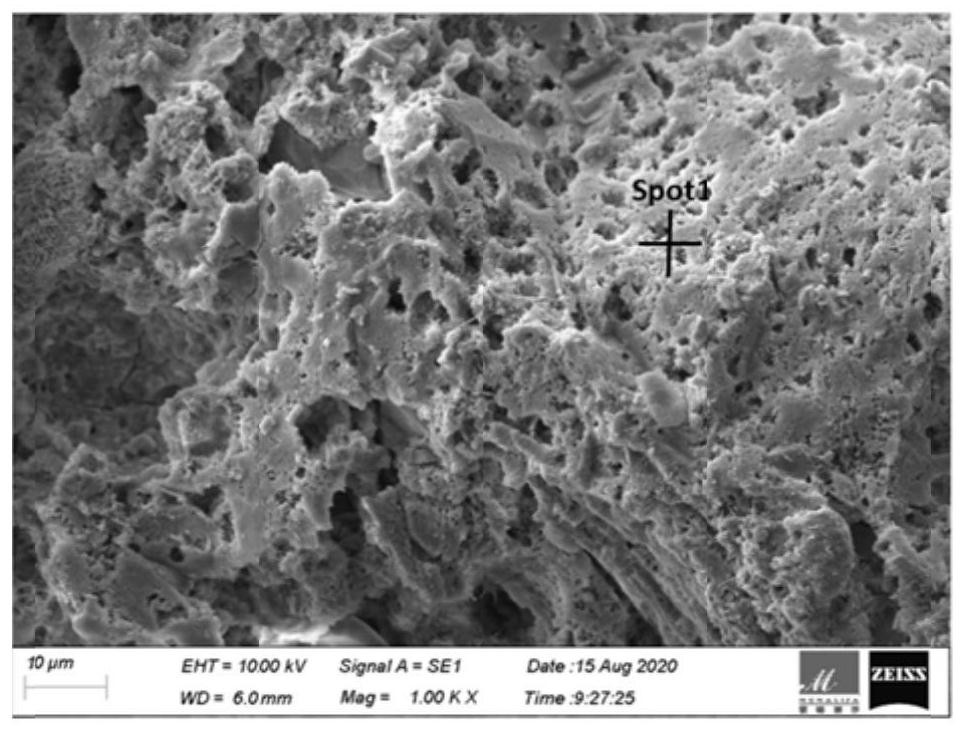

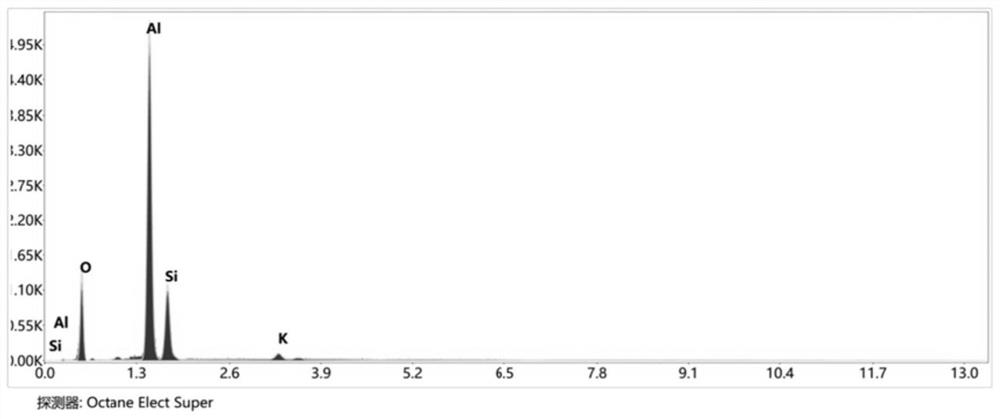

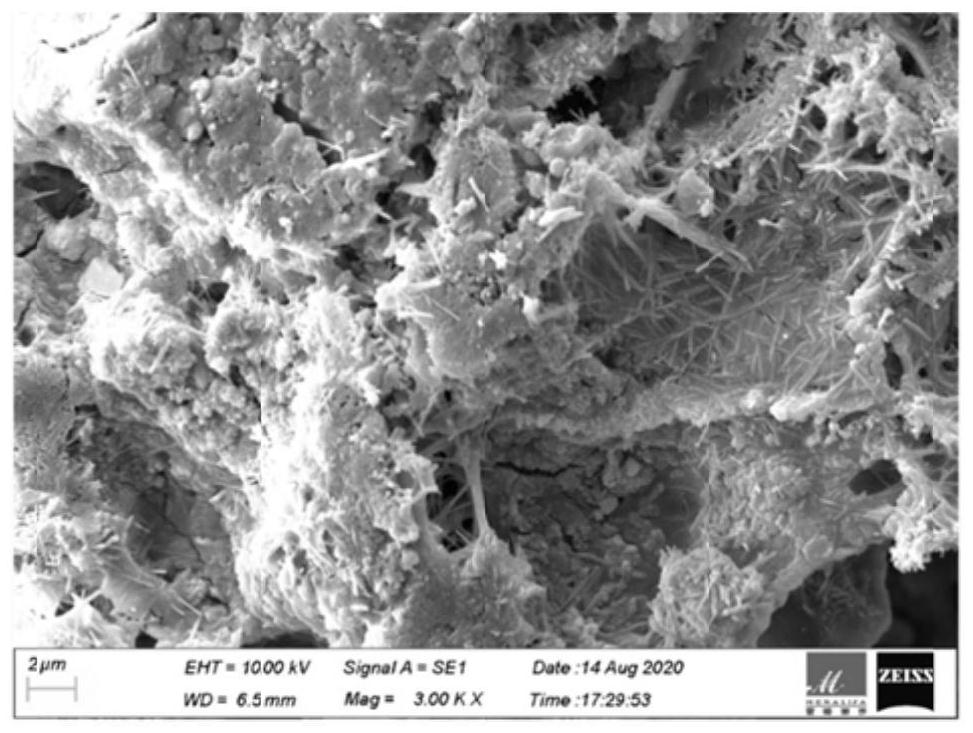

Image

Examples

Embodiment 1

[0039] 1) According to a specific stoichiometric ratio, 8 raw materials of calcined alumina, magnesia, nanoscale fused silica, monazite, bentonite, pyrophyllite, black talc, and potassium albite feldspar are uniformly mixed. Then, based on the quality of the mixed raw materials, nano-scale aluminum powder and sodium tripolyphosphate were added thereto, followed by ball milling, and then the ball milled product was passed through an 80-mesh sieve, and the undersize was collected and dried to obtain powder A. Among them, the mass ratio of calcined alumina, magnesia, nanoscale fused silica, monazite, bentonite, pyrophyllite, black talc and potassium albite feldspar is 30:5:20:10:1:5:5:10, mixed The mass percentage of aluminum powder added to powder A is 5%, the particle size is 100nm, and the mass percentage of sodium tripolyphosphate is 0.5%.

[0040] 2) The powder A is subjected to iron removal, sieving, pulping, spray granulation and other processes to obtain green body powder...

Embodiment 2

[0044] 1) According to a specific stoichiometric ratio, 8 raw materials of calcined alumina, magnesia, nanoscale fused silica, monazite, bentonite, pyrophyllite, black talc, and potassium albite feldspar are uniformly mixed. Then, based on the quality of the mixed raw materials, nano-scale aluminum powder and sodium tripolyphosphate were added thereto, followed by ball milling, and then the ball milled product was passed through a 120-mesh sieve, and the undersize was collected and dried to obtain mixed powder A. Among them, the mass ratio of calcined alumina, magnesia, nanoscale fused silica, monazite, bentonite, pyrophyllite, black talc and potassium albite feldspar is 35:10:25:15:3:10:10:15, mixed The mass percentage of aluminum powder added to powder A is 10%, the particle size is 300nm, and the mass percentage of sodium tripolyphosphate is 1.2%.

[0045] 2) The powder A is subjected to iron removal, sieving, pulping, spray granulation and other processes to obtain green b...

Embodiment 3

[0049] 1) According to a specific stoichiometric ratio, 8 raw materials of calcined alumina, magnesia, nanoscale fused silica, monazite, bentonite, pyrophyllite, black talc, and potassium albite feldspar are uniformly mixed. Then, based on the quality of the mixed raw materials, nano-scale aluminum powder and sodium tripolyphosphate were added thereto, followed by ball milling, and then the ball milled product was passed through a 100-mesh sieve, and the undersize was collected and dried to obtain powder A. Among them, the mass ratio of calcined alumina, magnesia, nanoscale fused silica, monazite, bentonite, pyrophyllite, black talc and potassium albite feldspar is 32:8:22:12:2:8:7:13. The mass percentage of aluminum powder added to the mixed powder A is 8%, the particle size is 220nm, and the mass percentage of sodium tripolyphosphate is 0.7%.

[0050] 2) The powder A is subjected to iron removal, sieving, pulping, spray granulation and other processes to obtain green body po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com