System and method for preparing large-size blue iron stone based on kitchen waste hydrothermal carbonization liquid

A technology for hydrothermal carbonization and kitchen waste, which is applied in chemical instruments and methods, water pollutants, anaerobic digestion treatment, etc. Problems such as poor cyanite purity, to achieve good environmental benefits, avoid oxidation problems, and good application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

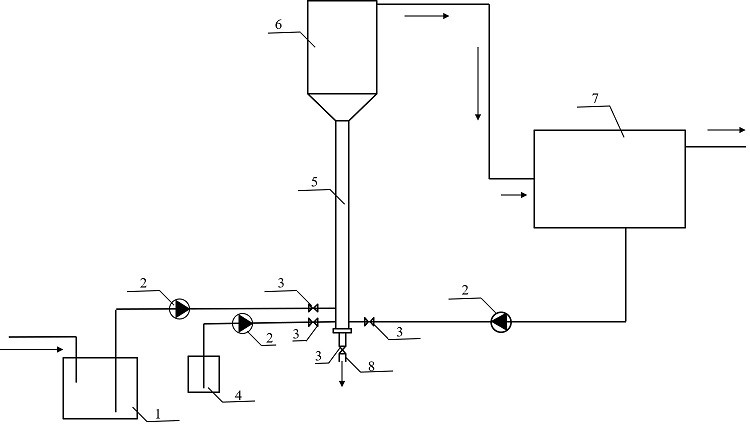

Image

Examples

Embodiment 1

[0032] The following steps were used to prepare large-sized blue-ironite recovery phosphate from kitchen waste hydrothermal carbonization liquid:

[0033] (1) Adjust the pH of the hydrothermal carbonization solution of kitchen waste to 6.0~7.5 in the adjustment pool;

[0034] (2) After adjusting the pH value, the hydrothermal carbonization liquid of kitchen waste enters the two-stage fluidized bed from the bottom. m / h;

[0035] (3) Inoculate anaerobic sludge in the fluidized bed;

[0036] (4) The iron salt solution in the trivalent iron source pool enters the two-stage fluidized bed from the bottom;

[0037] (5) After the reaction, the hydrothermal carbonization liquid of kitchen waste overflows from the second-stage fluidized bed, and the effluent flows to the reflux pool by gravity. The outlet water overflows and discharges from the top of the backflow pool, and the backflow flow rate is 10 to 25 times that of the inflow water flow rate;

[0038] (6) An emptying pipe is ...

Embodiment 2-8

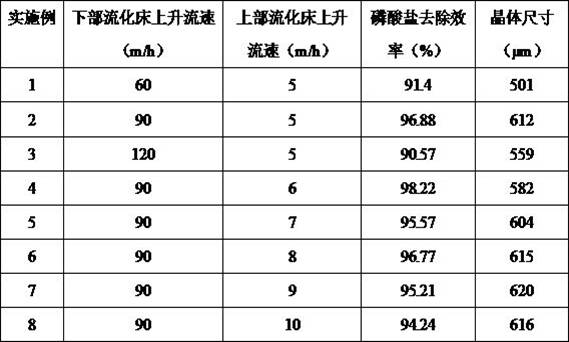

[0042] The ascending flow rate of the two-stage fluidized bed was changed according to the parameters in Table 1, and other process parameters were the same as in Example 1.

[0043] The ascending flow rate, phosphate removal efficiency and crystal size of each embodiment are shown in Table 1.

[0044] Table 1 The rising flow rate and phosphate removal efficiency, crystal size of each embodiment

[0045]

[0046] It can be seen from Table 1 that the removal efficiency of phosphate and the size of blue iron in the fluidized bed are mainly affected by the rising flow rate of the lower fluidized bed, and the removal efficiency of phosphate and the size of blue iron increase with the rising flow rate of the first stage First increase and then decrease. The ascending flow rate of the upper fluidized bed has little effect on the removal efficiency of phosphate and the size of bluestone. Each example shows that the method provided by the present invention uses a two-stage fluidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com