Production formula and process of 24K new pure gold

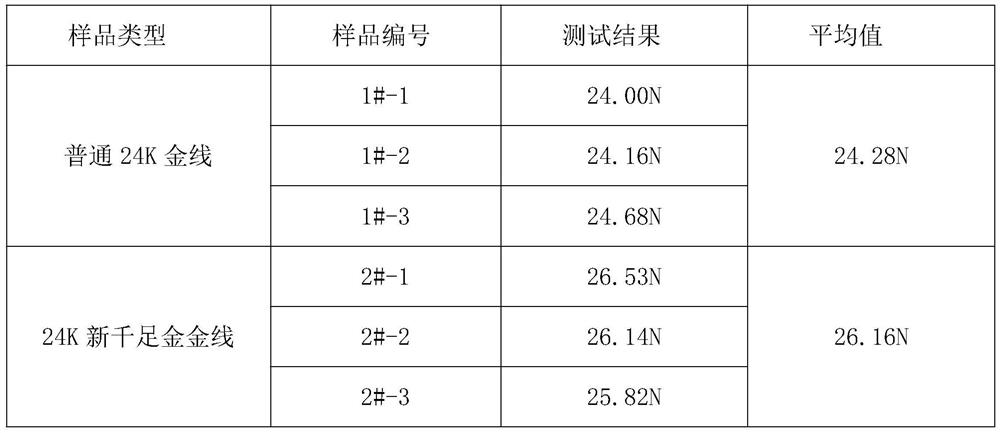

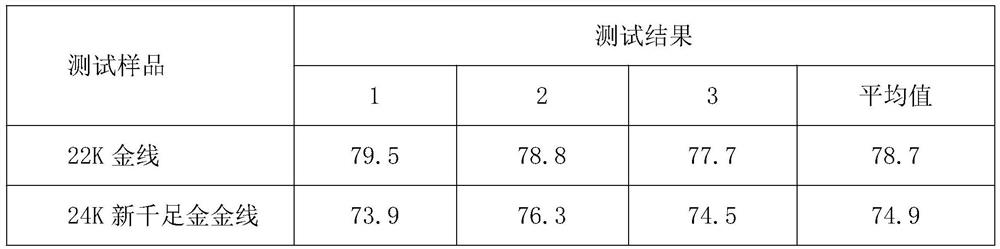

A technology for producing formula and new pure gold, applied in the field of pure gold, it can solve the problems of easy breaking of gold, soft gold texture, easy to have scratches, etc., to improve hardness and scratch resistance, high tensile force and hardness, and prevent oxidation problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the embodiment of the present invention, a production formula of 24K new pure gold is prepared by including the following raw materials in parts by weight: 999.3 parts of gold and 0.7 parts of metal alloy, and the metal alloy is prepared by including the following raw materials in parts by weight: copper 0.53 parts of silver, 0.03 parts of silver, 0.02 parts of platinum, 0.04 parts of zinc, and 0.08 parts of trace metal elements.

Embodiment 2

[0027] In the embodiment of the present invention, a production formula of 24K new pure gold is prepared from the following raw materials in parts by weight: 999.5 parts of gold and 0.5 part of metal alloy, and the metal alloy is prepared from raw materials in the following weight ratio: copper 0.37 parts of silver, 0.02 parts of silver, 0.015 parts of platinum, 0.03 parts of zinc, and 0.065 parts of trace metal elements.

Embodiment 3

[0029] In the embodiment of the present invention, a production formula of 24K new pure gold is prepared from the following raw materials in parts by weight: 999.5 parts of gold and 0.5 part of metal alloy, and the metal alloy is prepared from raw materials in the following weight ratio: copper 0.37 parts of silver, 0.02 parts of silver, 0.015 parts of platinum, 0.03 parts of zinc, and 0.065 parts of trace metal elements.

[0030] The technique of embodiment 1-3, comprises the following steps:

[0031] 1. The general department distributes the prepared gold material to the gold melting department. The gold melting department gets the gold material, puts the gold material into the gold melting furnace first, and then puts the alloy metal in after the gold is melted, and stirs for 2-3 minutes , the stirring tool is a quartz rod. The temperature of the gold melting furnace is within 1050-1080 degrees Celsius. The time for melting gold is 5-10 minutes. In the strip mold, after na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com