Centrifugal sample separation equipment for agricultural product detection, and centrifugal sample separation method thereof

A technology for agricultural products and equipment, applied in the field of centrifugal detection equipment, can solve problems such as poor juice purity, juice detection errors, browning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

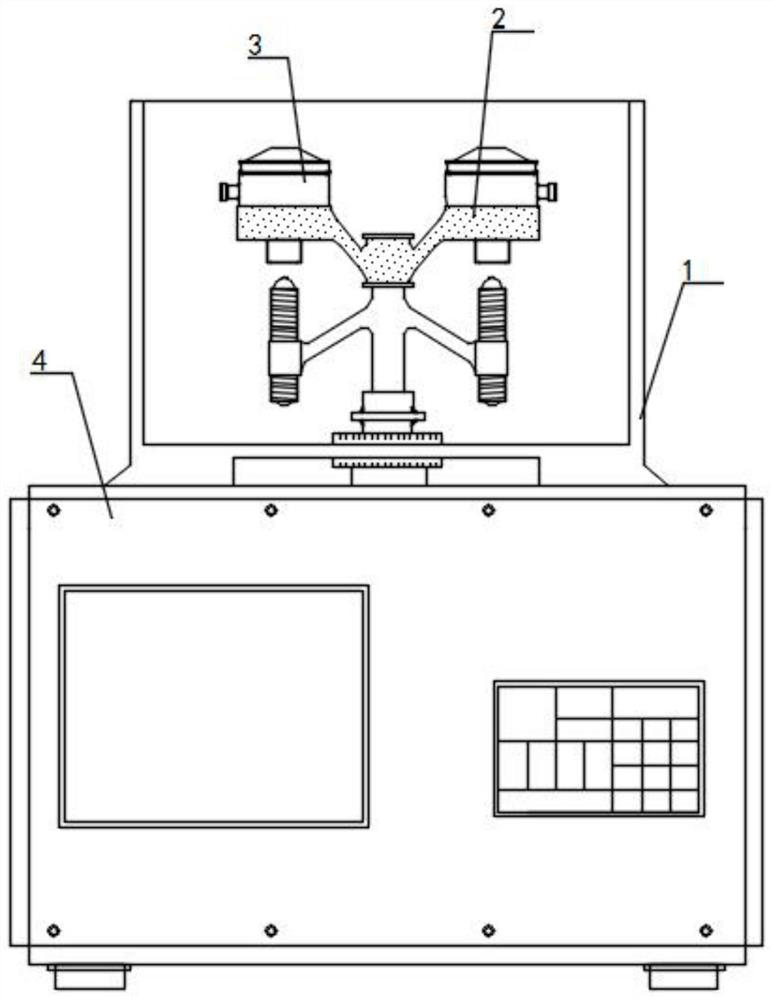

Embodiment 1

[0031] like Figure 1-7 As shown, the centrifugal sampling equipment used for agricultural product detection includes a body 4 and a box body 1, the top of the body 4 is fixedly connected with a box body 1, and a centrifugal frame 2 is arranged in the box body 1; the centrifugal frame 2 includes a collar 21, Bearing sleeve 22, internal thread sleeve 23, shaft rod 24 and connecting handle 25, the shaft rod 24 is fixedly connected to the drive shaft at 4 places of the body, and the side wall of the shaft rod 24 is symmetrically fixed with connecting handle 25, and the connecting handle 25 is in addition One end is fixedly connected with an internal thread sleeve 23; a bearing sleeve 22 is arranged above the shaft rod 24, and the bearing sleeve 22 is sleeved to the top end of the shaft rod 24; the side wall of the bearing sleeve 22 is symmetrically fixed with a collar 21; the centrifugal frame 2 A material processing device 3 is arranged at the place, and the material processing ...

Embodiment 2

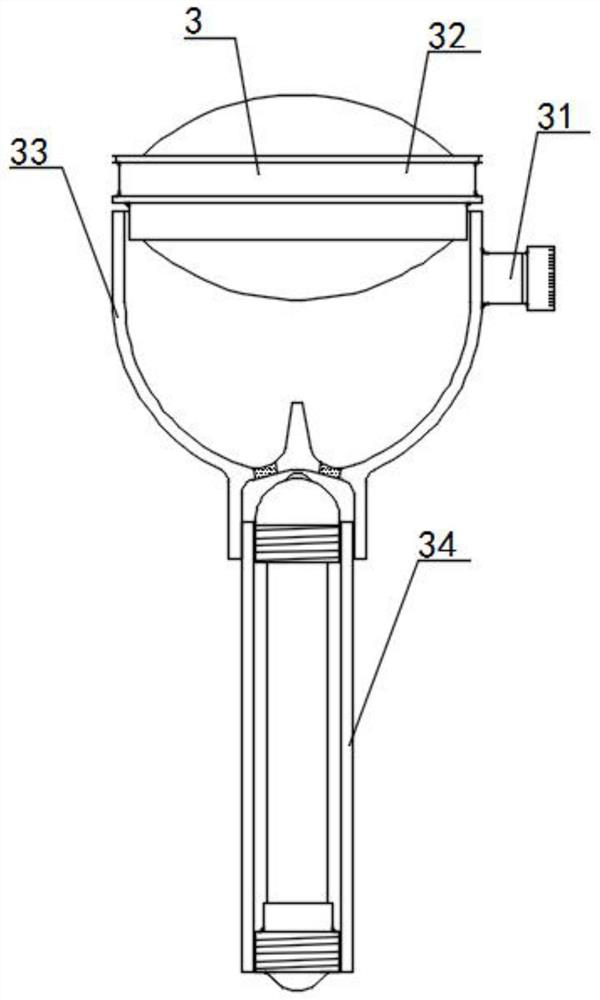

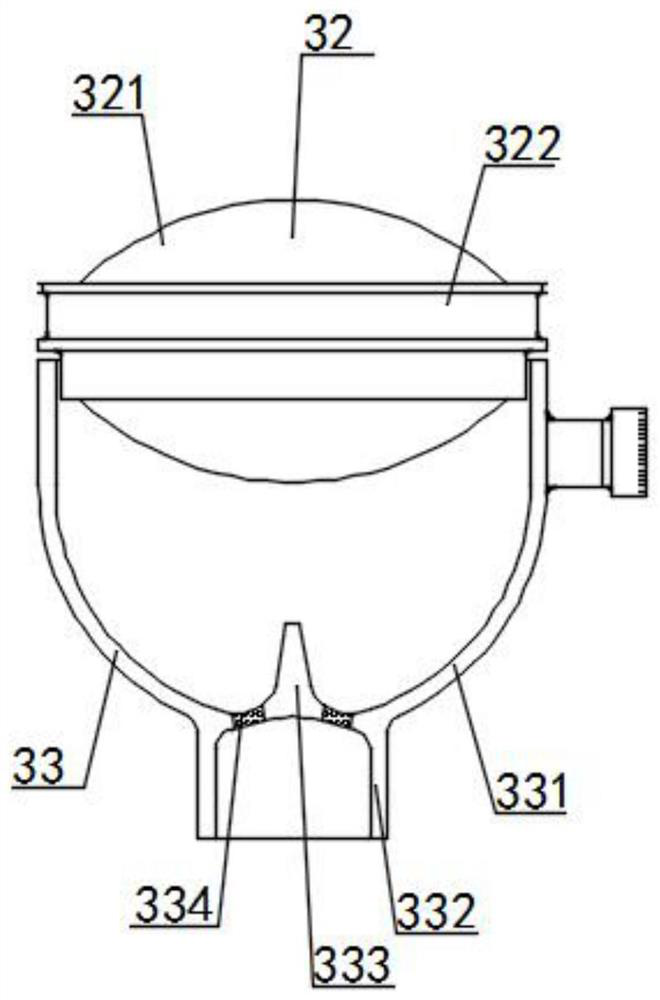

[0035] like Figure 1-4As shown, the centrifugal sampling equipment used for the detection of agricultural products, the juicer cup 33 includes a cup body 331, an internally threaded sleeve 332, a cone 333 and a filter plug 334, and the collar 21 is clamped with a cup body 331, and the cup body 331 The bottom end of the inner thread sleeve 332 is integrally formed, and a cone 333 is arranged on the inner side of the joint between the inner thread sleeve 332 and the cup body 331, and the annular edge of the cone body 333 is fixedly connected to the inner thread sleeve 332 and the cup body 331 The annular joints of the cones 333 and the surface of the cone 333 are equally divided into holes in a circular distribution near the edge of the ring, and a filter plug 334 is embedded in the holes; the pressing assembly 32 includes a rubber air bag 321 and a socket 322, and a juicer cup 33 The port is covered with a socket 322, the socket 322 is divided into an insertion end and an expo...

Embodiment 3

[0040] like Figure 2-6 As shown, the centrifugal sampling equipment used for the detection of agricultural products,

[0041] The contact valve 341 includes a ball groove 3411, a ball body 3412, a plug 3413, an opening and closing structure 3414 and an introduction notch 3415. The upper port of the externally threaded pipe 344 is bolted with a plug 3413, and the ball cap at the plug 3413 is socketed and fixed with an opening and closing structure. 3414, above the opening and closing structure 3414, there is a ball groove 3411 at the ball cap, and a ball 3412 is set inside the ball groove 3411; the outer periphery of the ball groove 3411 is provided with a circular distribution on the surface of the ball cap at the plug 3413. 3415; wherein the opening and closing structure 3414 includes a ring body 34141, a notch 34142, a ball cap-shaped rubber sleeve 34143, a spacer ring 34144, a spring 34145, a test tube cover 34146 and a ball pad 34147, and the ring body is fixed in the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com