In-situ nano-copper paste and preparation process and application thereof

A preparation process, nano-copper technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve long-term stable storage, good dispersion, and avoid agglomeration problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

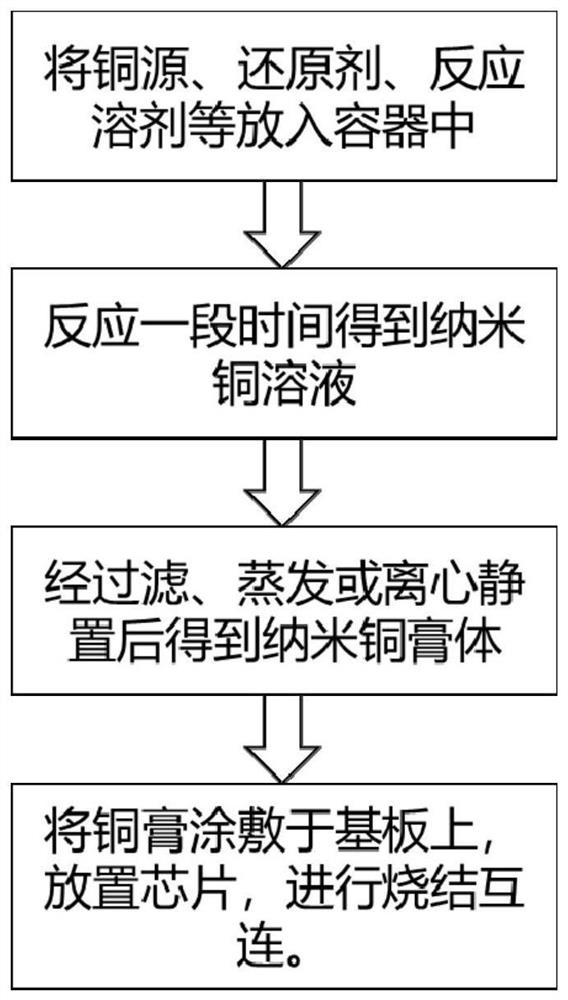

[0045] This embodiment provides an in-situ nano-copper paste, and using the in-situ nano-copper paste for sintering interconnection, such as figure 1 As shown, the preparation process is as follows:

[0046] S1. Preparation of nano-copper solution

[0047] Under the condition of 50°C, copper acetate and ascorbic acid were put into 500mL ethylene glycol solvent for reaction according to the molar ratio of 1:6, and the nano-copper solution was obtained after reaction for 20 minutes;

[0048] S2. Preparation of in-situ nano copper paste

[0049] Pour the nano-copper solution obtained in S1. into a centrifuge tube, centrifuge in a centrifuge for 5 minutes under the condition of 12000r / min, and then stir to obtain a uniform mass fraction of 80% in-situ nano-copper paste, nano-copper particles The particle size is 50-100nm.

[0050] Coat the paste on the copper substrate, cover the coated copper paste with the interconnect chip, put it into a hot-press furnace, and sinter it at 300...

Embodiment 2

[0052] This embodiment provides an in-situ nano-copper paste, and using the in-situ nano-copper paste for sintering interconnection, such as figure 1 As shown, the preparation method is as follows:

[0053] S1. Preparation of nano-copper solution

[0054] Under the condition of 80°C, copper hydroxide and ascorbic acid were put into 400mL terpineol solvent for reaction according to the molar ratio of 1:10, and the nano-copper solution was obtained after reaction for 30 minutes;

[0055] S2. Preparation of in-situ nano copper paste

[0056] Pour the nano-copper solution obtained in S1 into a rotary evaporator and evaporate it for 30 minutes at a rotation speed of 120r / min, an evaporation temperature of 200°C, and a vacuum of 180Pa, take it out and stir to obtain a uniform mass fraction of 85% in situ The nano-copper paste, the particle diameter of the nano-copper particles is 50-100nm.

[0057] Coat this paste on a silicon substrate, cover the coated copper paste with an inte...

Embodiment 3

[0059] This embodiment provides an in-situ nano-copper paste, and using the in-situ nano-copper paste for sintering interconnection, such as figure 1 As shown, the preparation process is as follows:

[0060] S1. Preparation of nano-copper solution

[0061] Under the condition of 65°C, put copper acetylacetonate and glucose into 300mL ethylene glycol solvent for reaction according to the molar ratio of 2:1, and obtain nano-copper solution after 10 minutes of reaction;

[0062] S2. Preparation of in-situ nano copper paste

[0063] Filter the nano-copper solution obtained in S1. through a microfiltration membrane, take out the filtered nano-copper solution and stir to obtain an in-situ nano-copper paste with a uniform mass fraction of 78%, and the particle size of the nano-copper particles is 50-100nm .

[0064] Coat this paste on a silicon carbide substrate, cover the coated copper paste with an interconnection chip, put it into a hot-press furnace, and sinter it at 260°C and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear force | aaaaa | aaaaa |

| Shear force | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com