Method for assembling and welding tube socket on positioning-free table

A welding method and non-positioning technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of wrinkling, uneven welding shrinkage, low production efficiency, etc. , to achieve the effect of improving machining accuracy, improving subsequent machining accuracy and production efficiency, and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

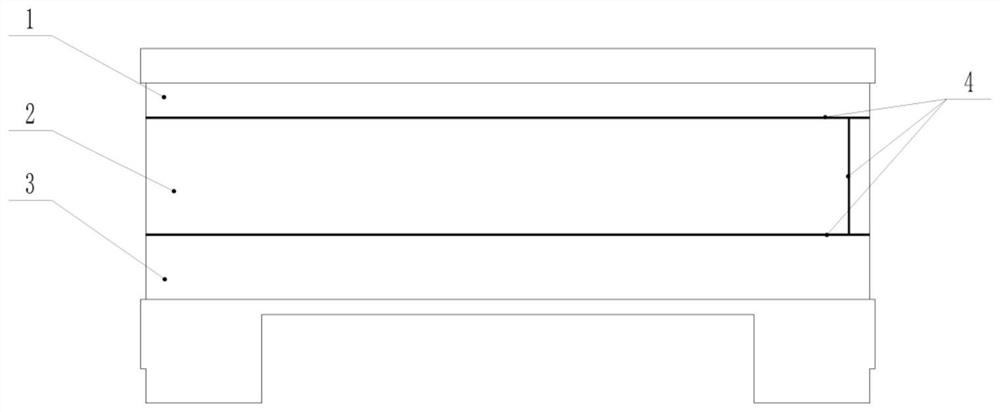

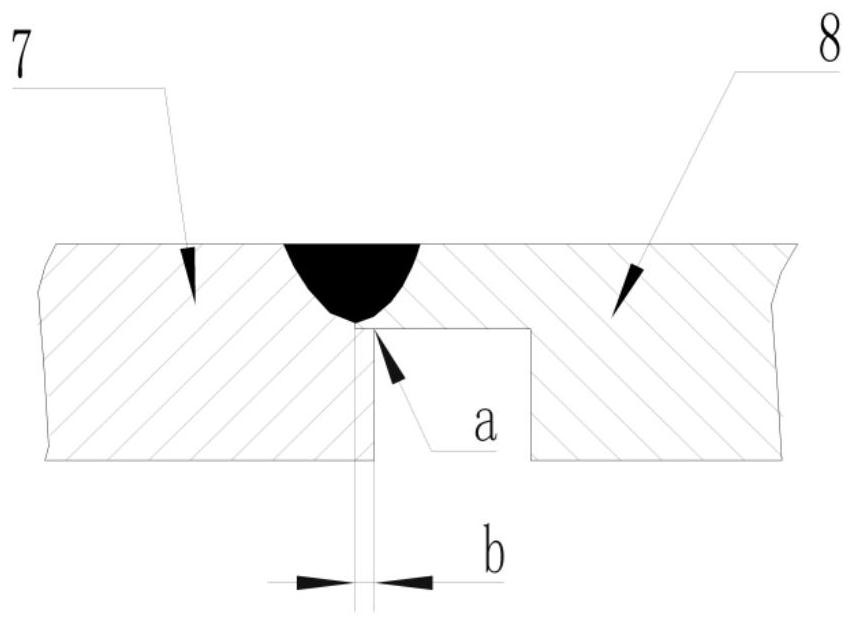

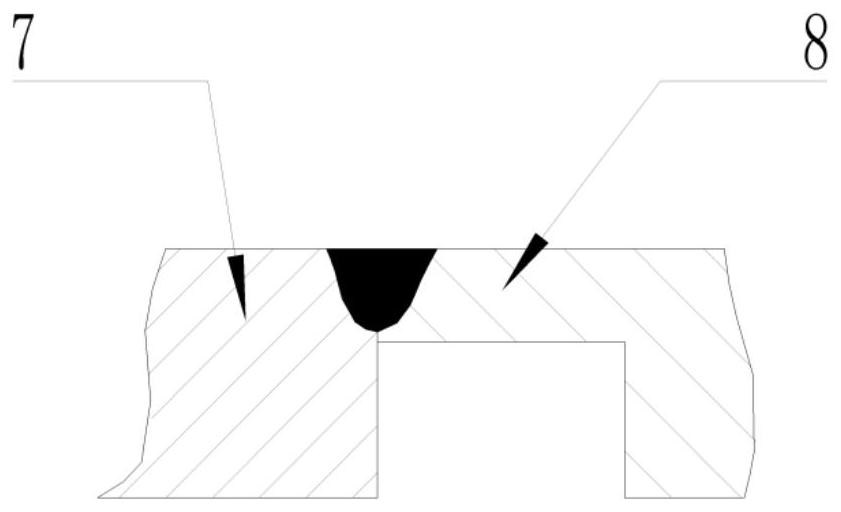

[0041] A method for assembling and welding tube bases without a positioning platform of the present invention, a new type of assembly and positioning structure is designed, and a structural form without a positioning platform (no locking bottom flush joints) is adopted, but the result of the tube base is complicated, the parts are many and scattered, and the increase Difficulty in assembly and positioning. Develop a new welding process method. The welding method is: assembly TIG spot welding + electron beam fixed spot welding + electron beam scanning welding and repair welding + defect manual repair welding when necessary.

[0042] A method for assembling and welding pipe sockets without a positioning platform, comprising the following steps:

[0043] Step 1: Design the structural form of the upper tube seat without a positioning pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com